Matters needing attention during the installation process of thermal gas mass flowmeters

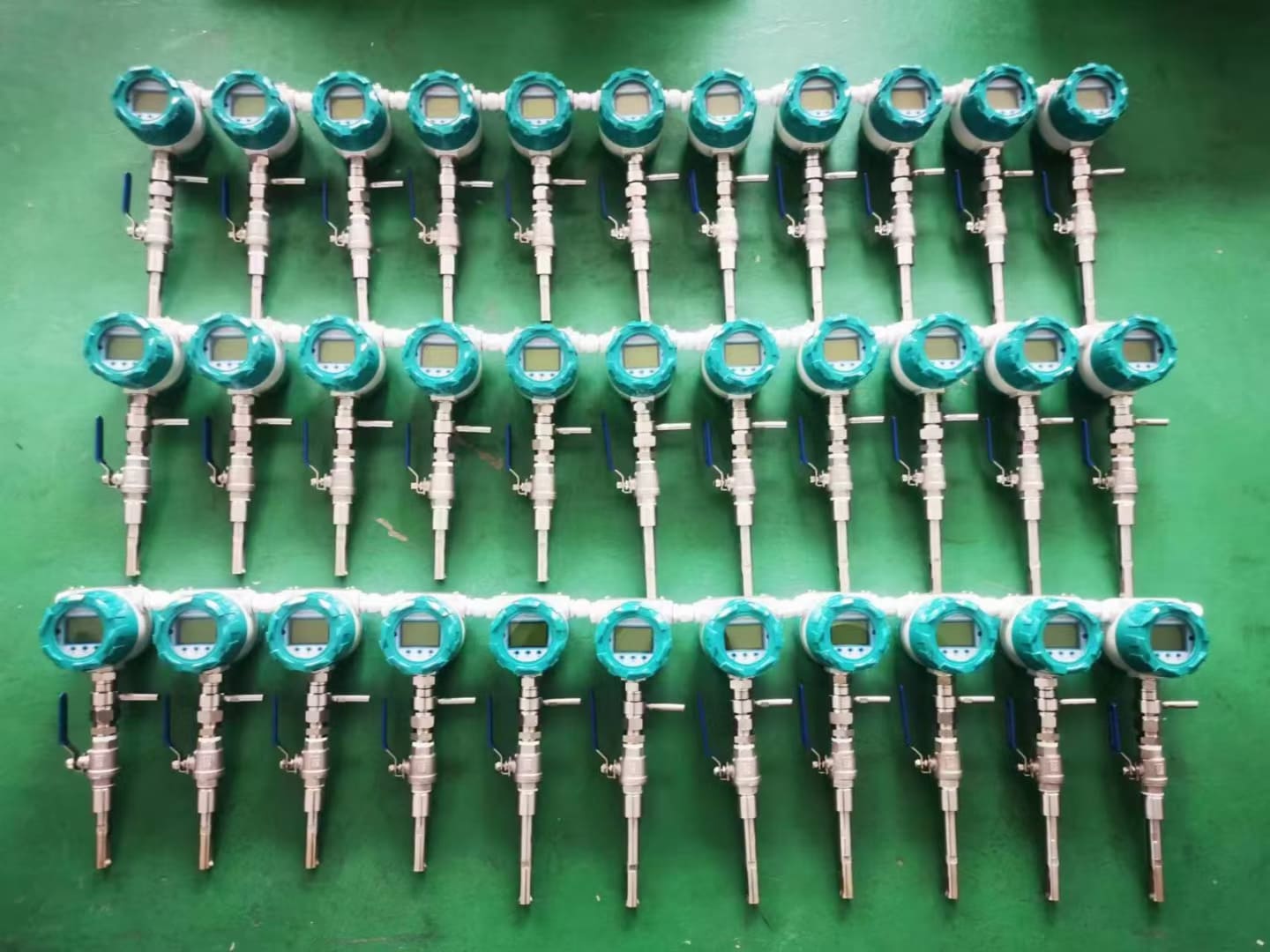

A thermal gas mass flowmeter is an instrument that measures the flow of fluids based on the principle of heat conduction. This instrument accurately measures gas flow by using the constant temperature difference method. It has the advantages of small size, high degree of digitalization, easy installation and accurate measurement. Today, let’s mainly talk about what matters need to be noted during the installation process of thermal gas mass flowmeters?

1. Installation and connection requirements for integrated type

1) If the converter is installed outdoors, an instrument box needs to be added to avoid rain and sun exposure.

2) It is prohibited to install in places with strong vibration or in environments with a large amount of corrosive gases.

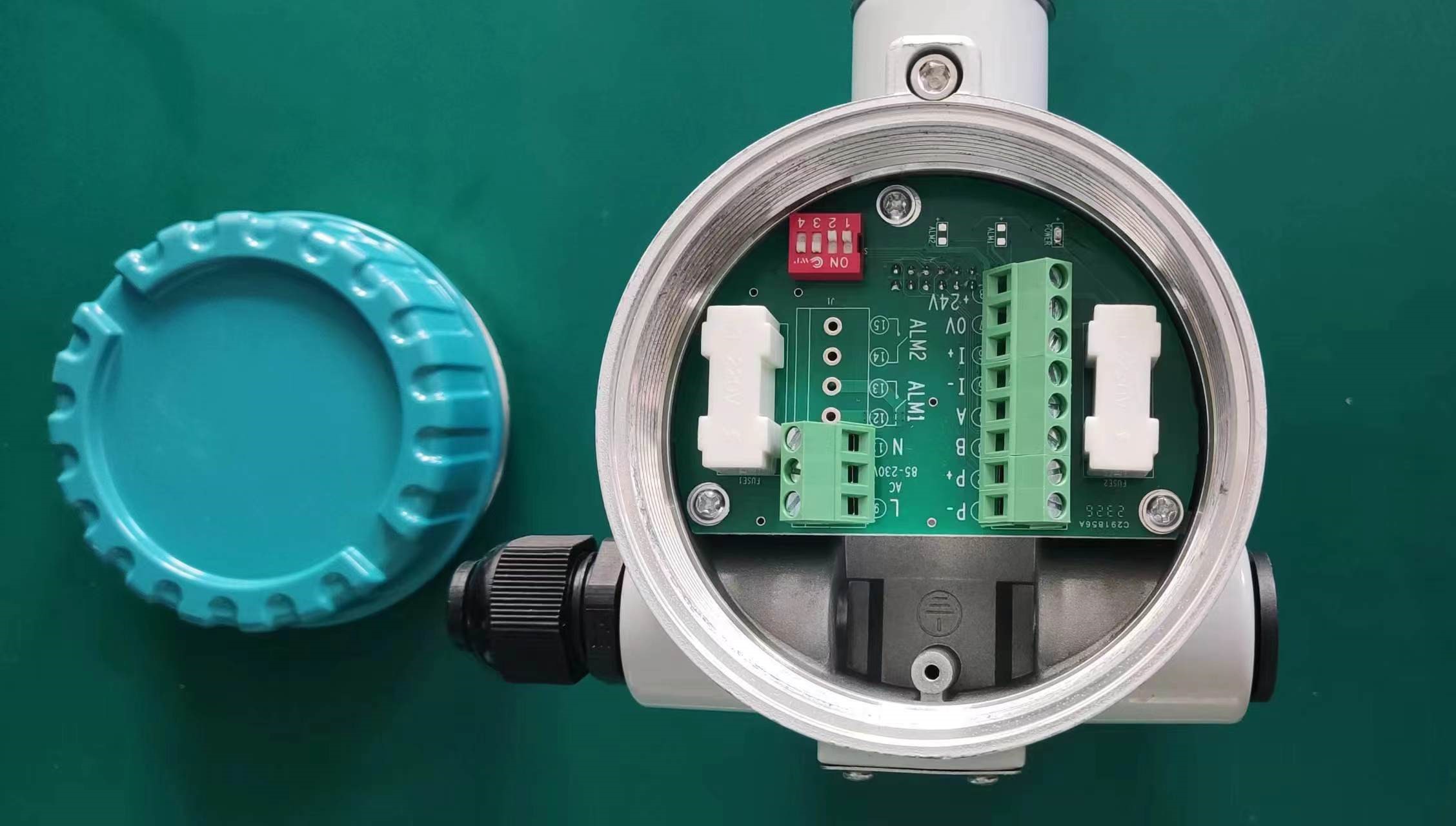

3) Do not share an AC power supply with equipment such as frequency converters and welding machines that pollute the power supply. If necessary, install a purified power supply for the converter.

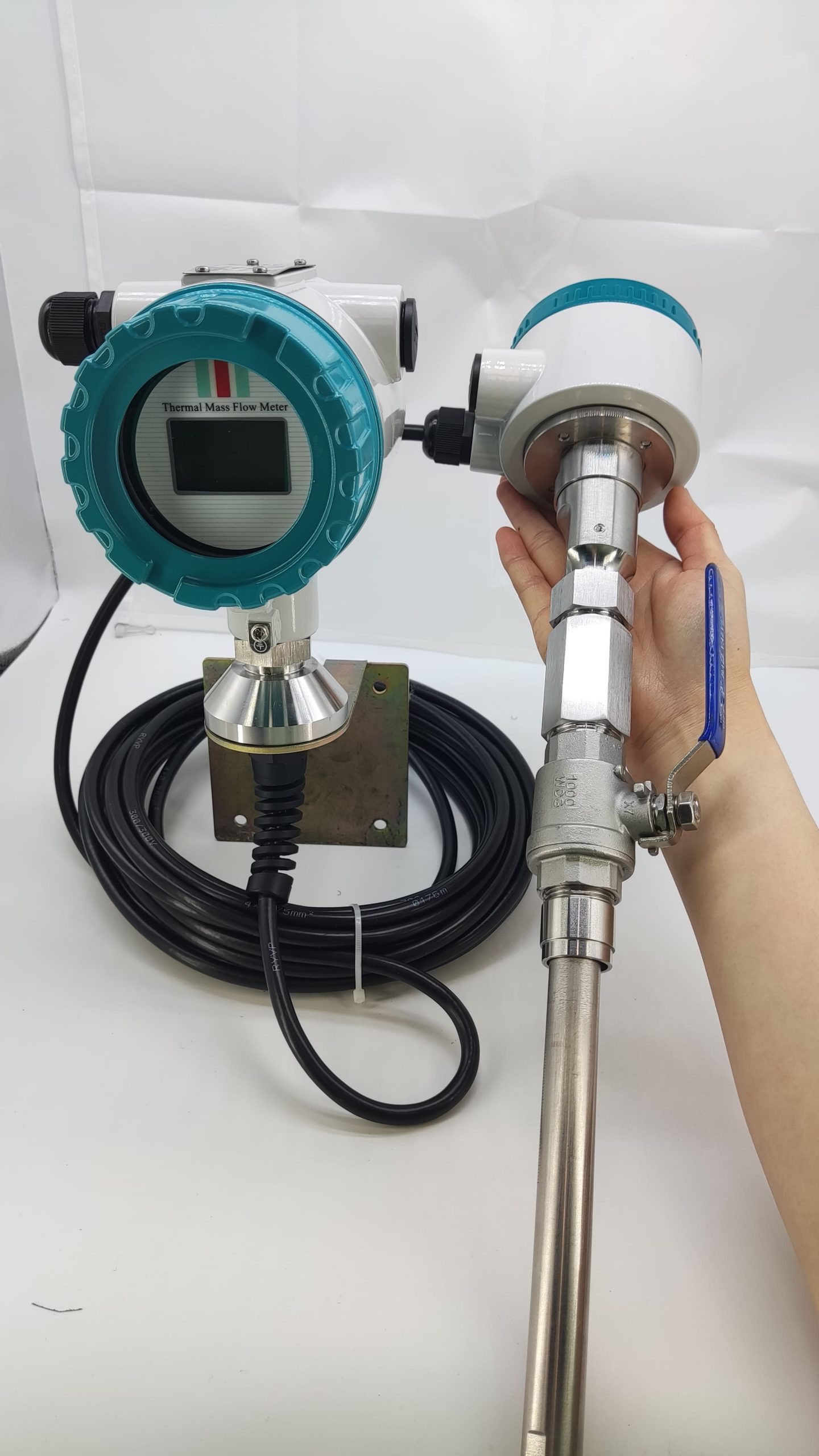

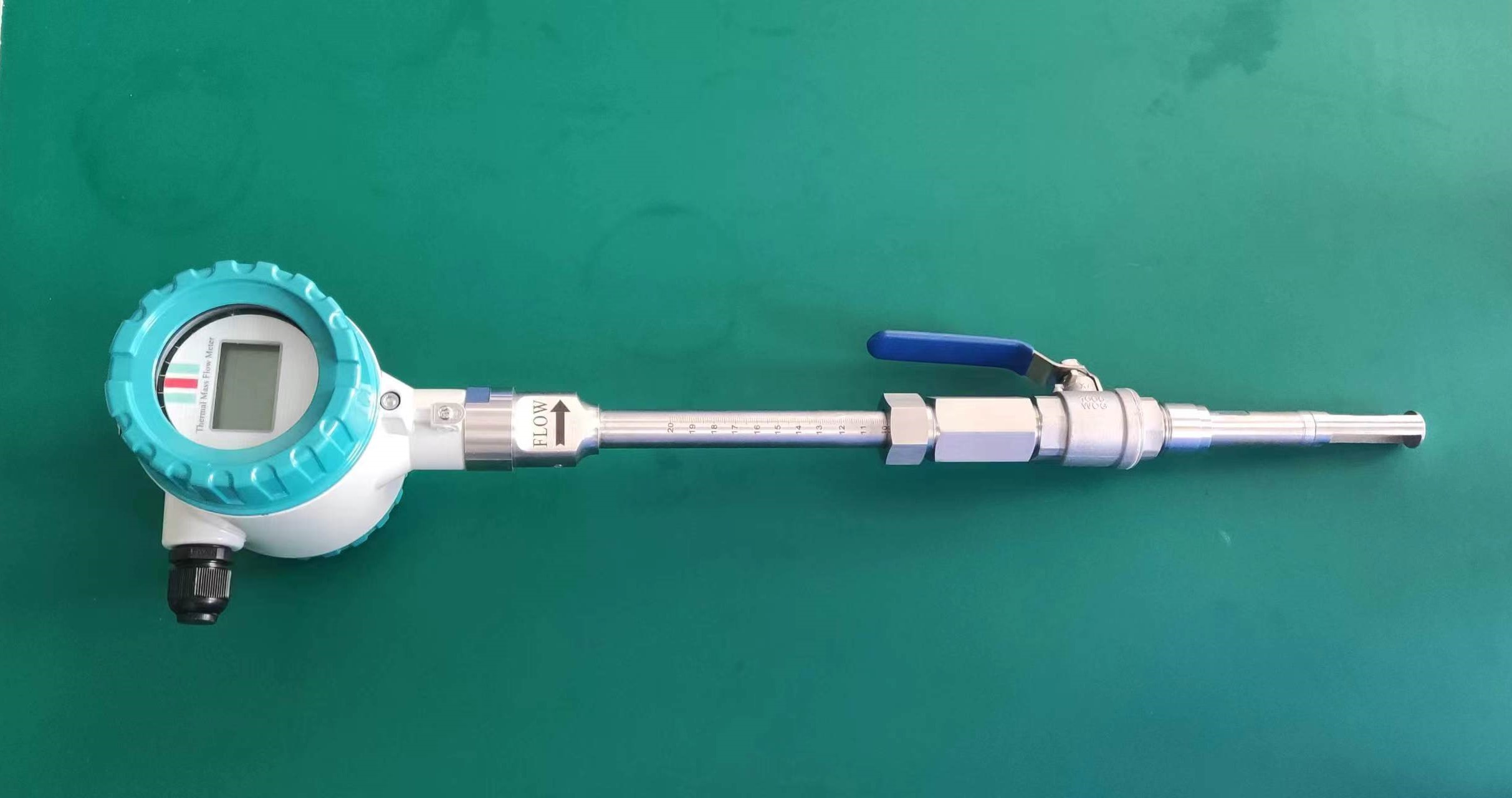

4) The integrated insertion type should be inserted into the center of the pipe to be measured. Therefore, the length of the measuring rod depends on the diameter of the pipe to be measured. Please specify this when placing an order. If it cannot be inserted into the center of the pipe, the calibration coefficient will be provided by the manufacturer to ensure accurate measurement.

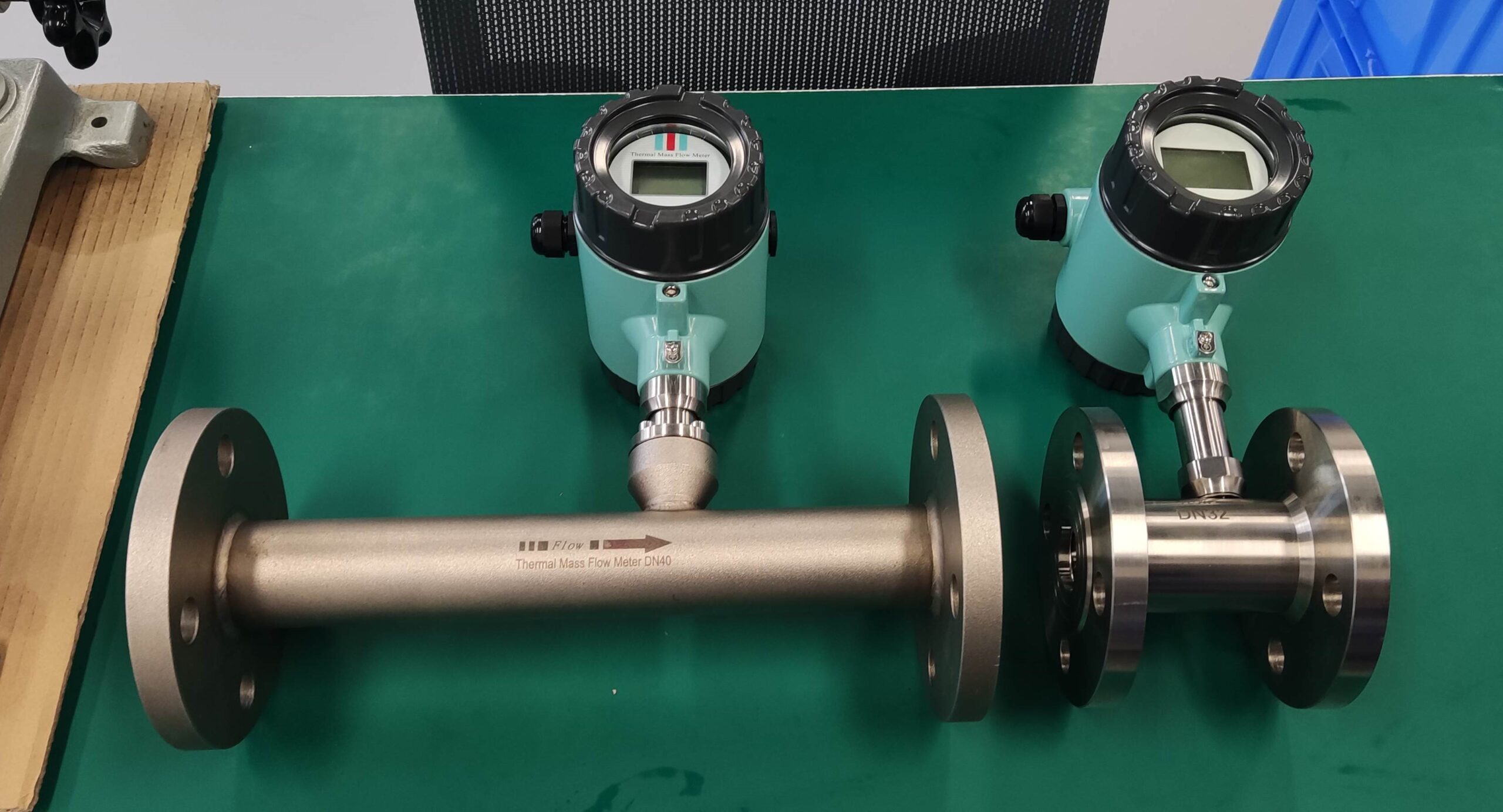

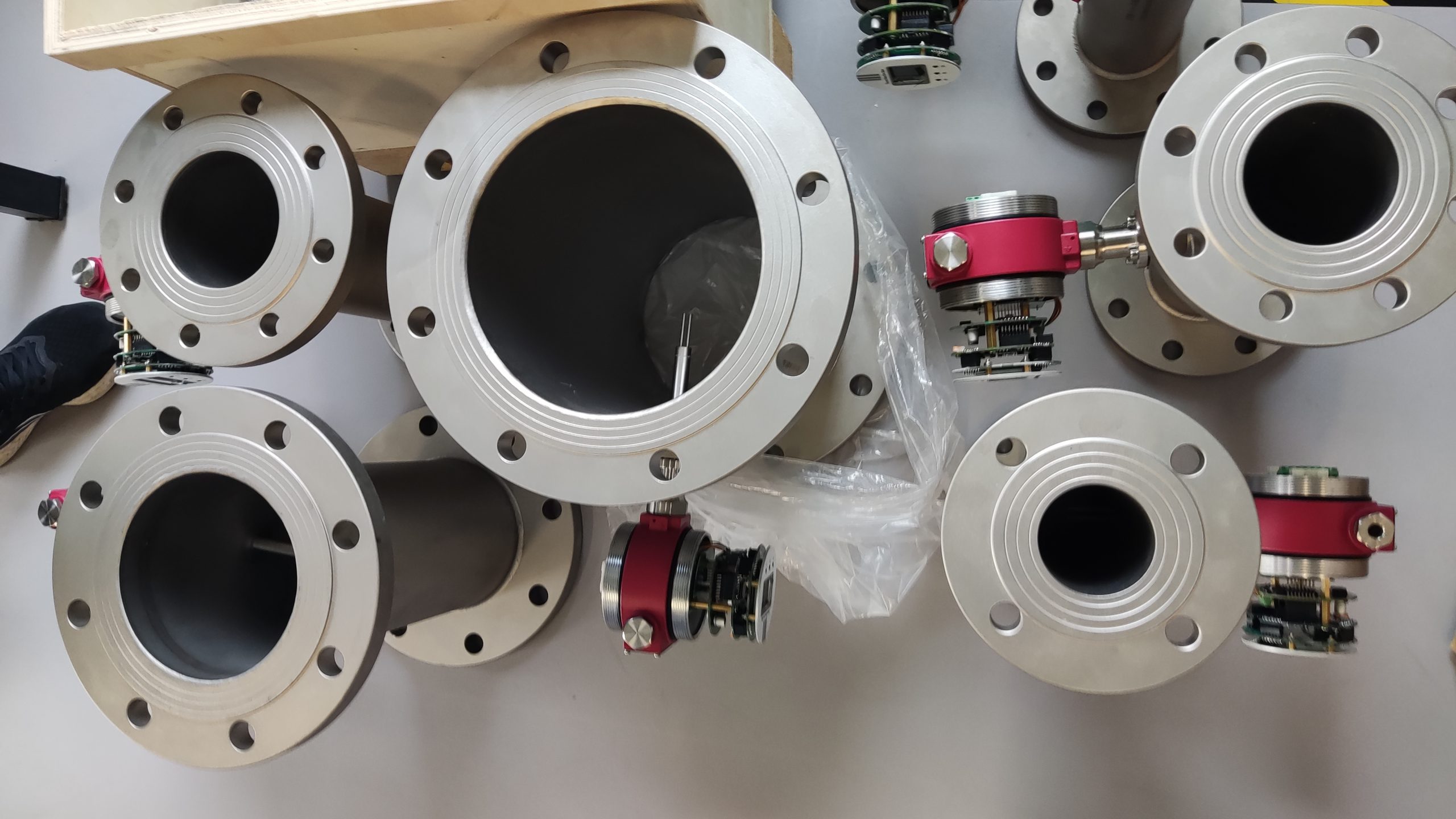

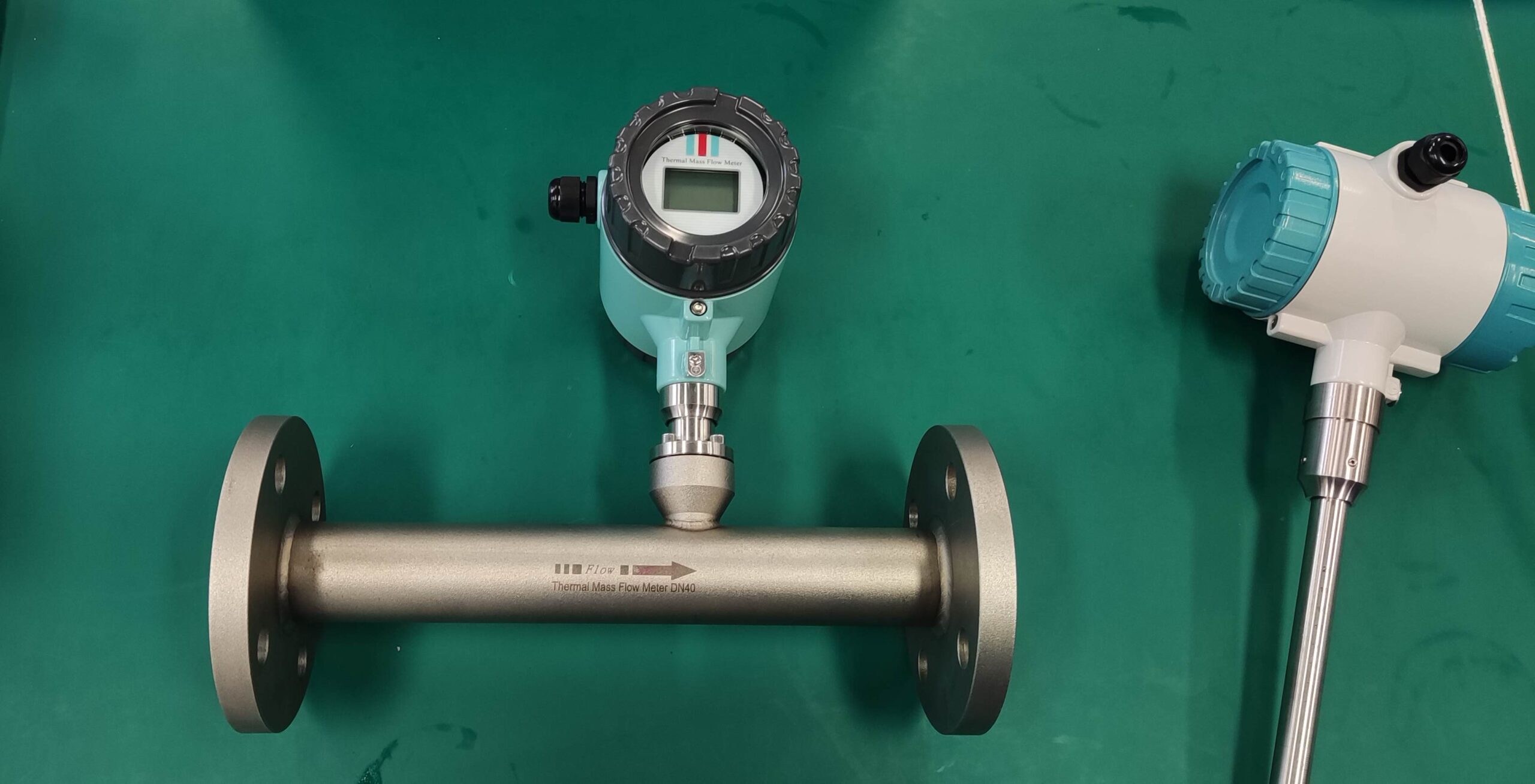

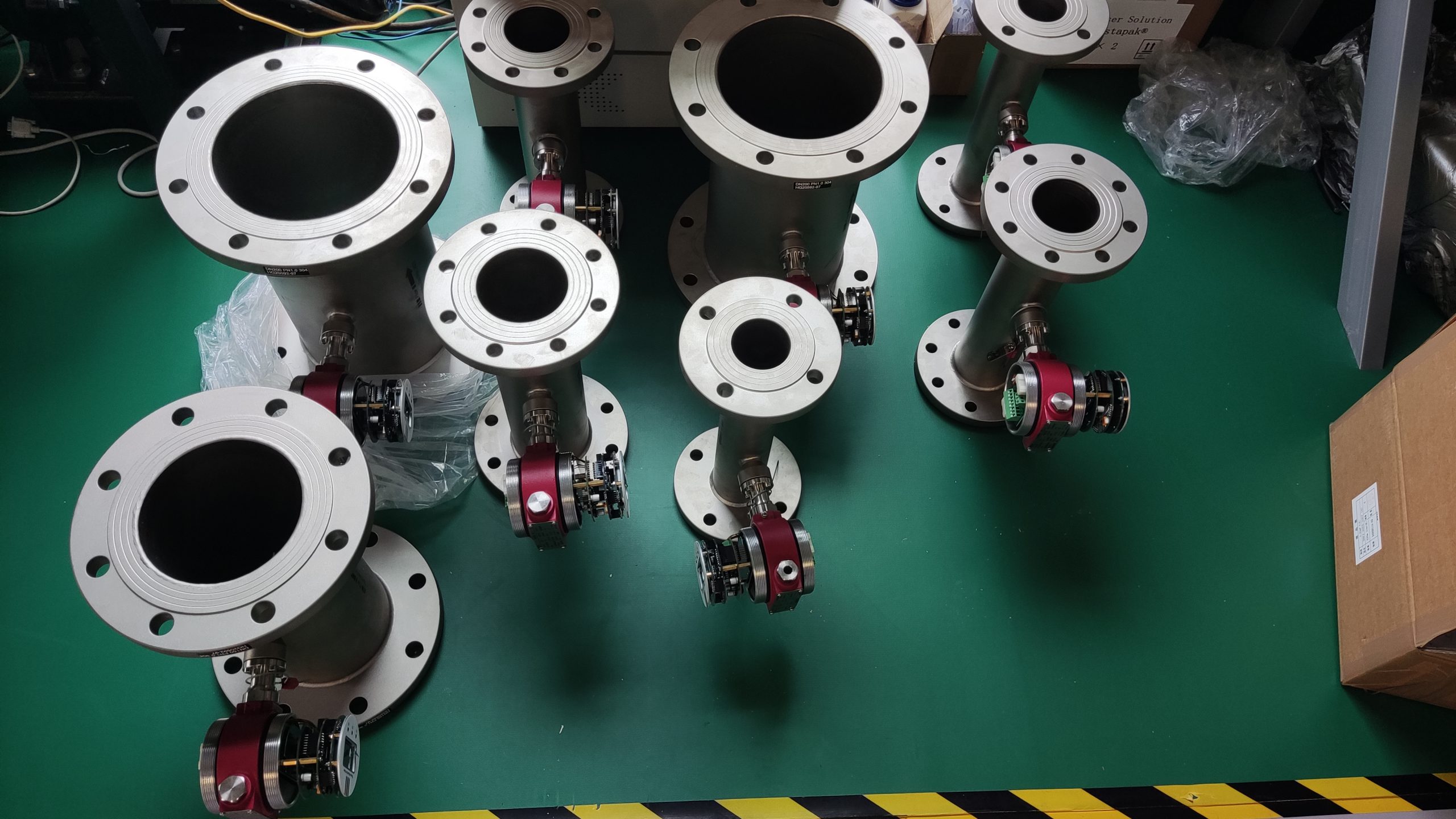

5) The integrated pipe section type adopts flange connection, which complies with the national standard GB/T9119-2000.

2. Installation of thermal gas mass flowmeters

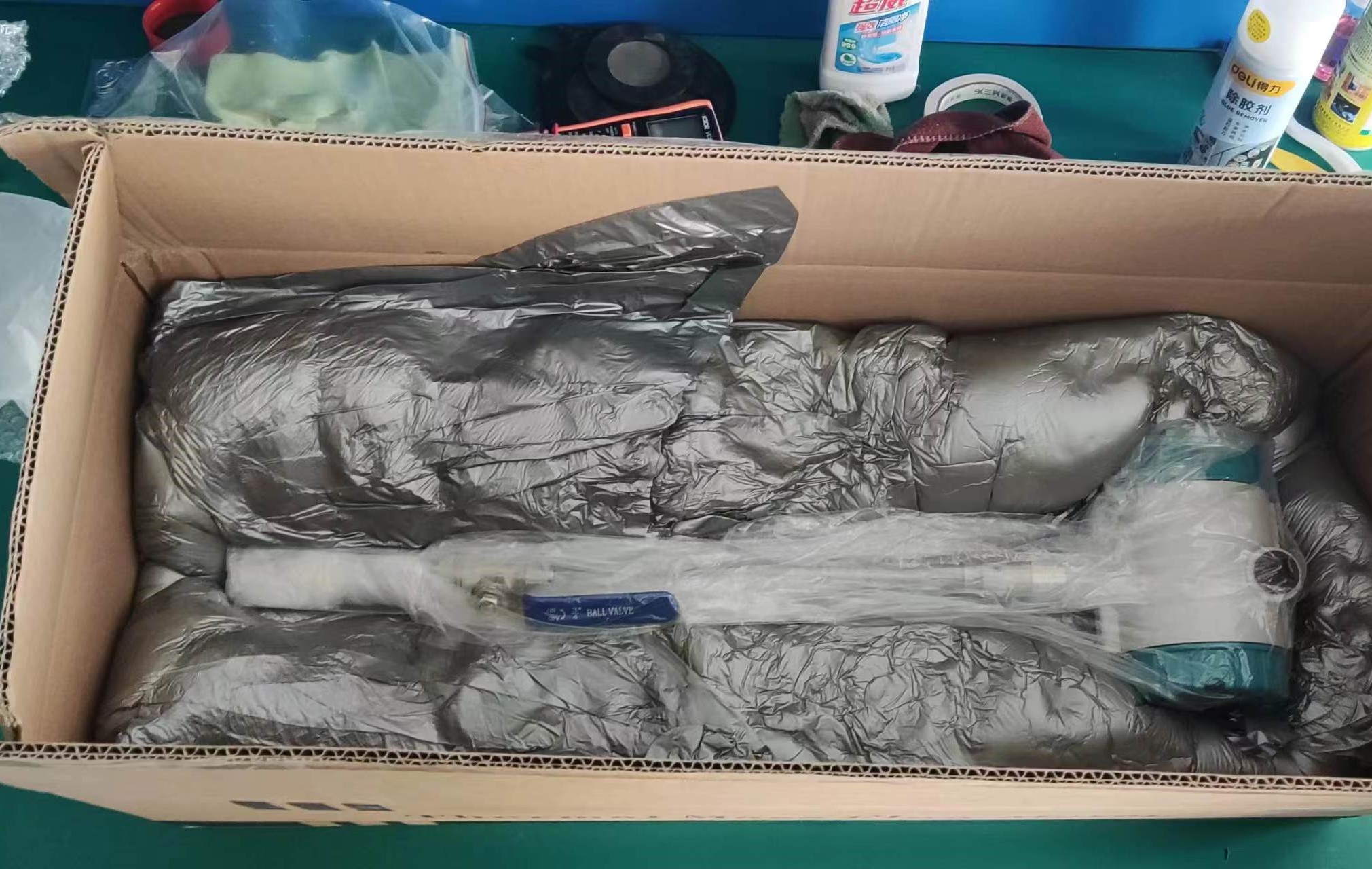

1) The integrated plug-in installation is provided with pipe connectors and valves by the manufacturer. For non-weldable pipes, the factory shall provide pipe clamps. For example, weldable pipes. First, weld the connecting parts to the pipeline. Then, install the valve and drill holes with a special tool. Finally, install the instrument. When maintaining the instrument, remove the instrument and close the valve without affecting normal production.

2) For pipe section installation, flanges of corresponding standards should be selected for connection.

3) When installing, it should be noted that the “Medium flow direction marking” on the instrument should be the same as the actual flow direction of the gas.

3. Commissioning and operation of thermal gas mass flowmeters

The potential on the instrument enters the measurement state. At this point, it is essential to input the data according to the actual working conditions.

4. Maintenance of thermal gas mass flowmeters

When opening the casing, be sure to cut off the power first.

2) When removing the sensor, pay attention to the pressure, temperature of the pipeline or whether the gas is toxic.

3) The sensor does not sense a small amount of dirt, but when used in a dirtiest environment, it should also be cleaned regularly. Otherwise, it will affect the measurement accuracy.