Problems needing attention when using plug-in electromagnetic flow timing

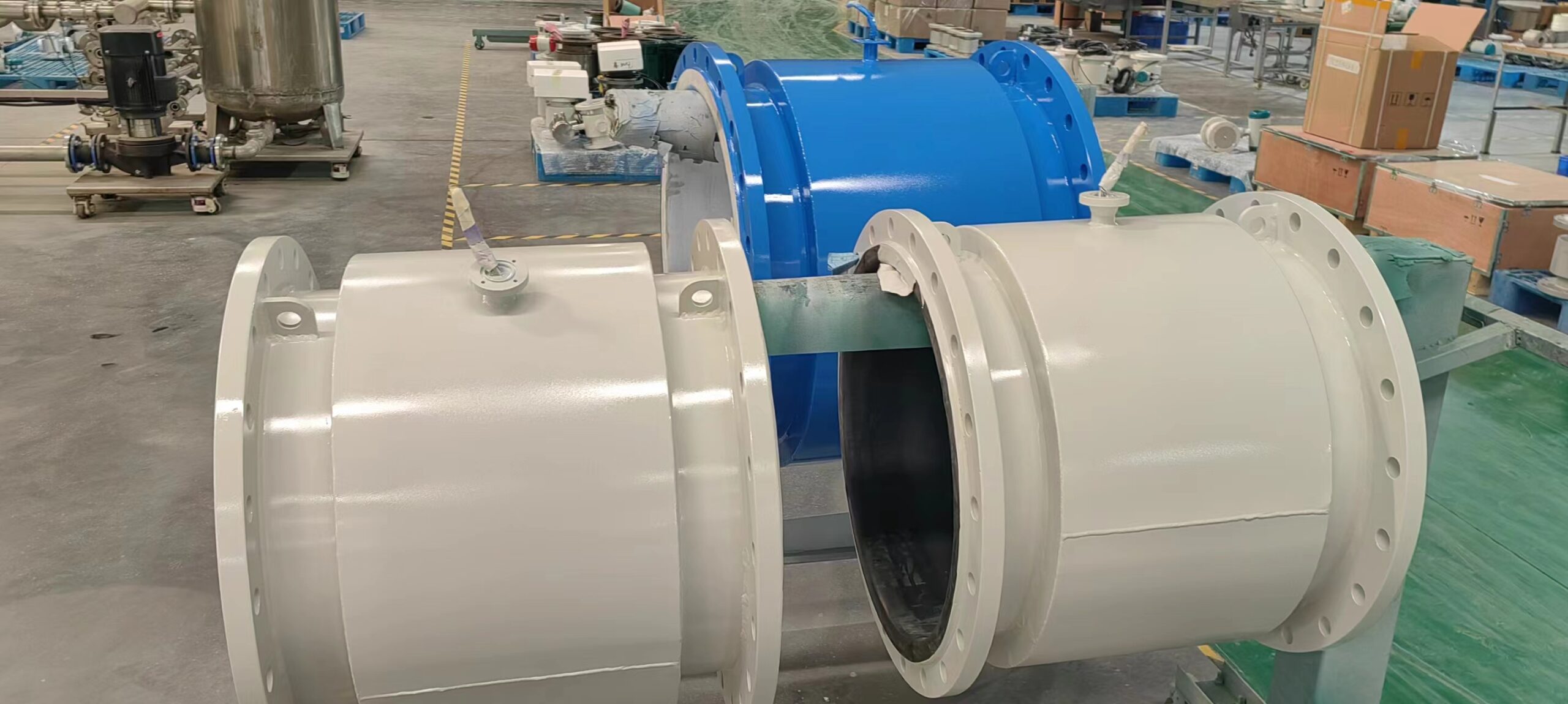

The plug-in electromagnetic flowmeter has a wide range of applications, and can be used to measure the volume flow of conductive liquid and slurry in closed pipelines in many fields such as petroleum, chemical industry, metallurgy, paper making, environmental protection, municipal management, water conservancy construction and so on.

What problems do we need to pay attention to when using the plug-in electromagnetic flow meter?

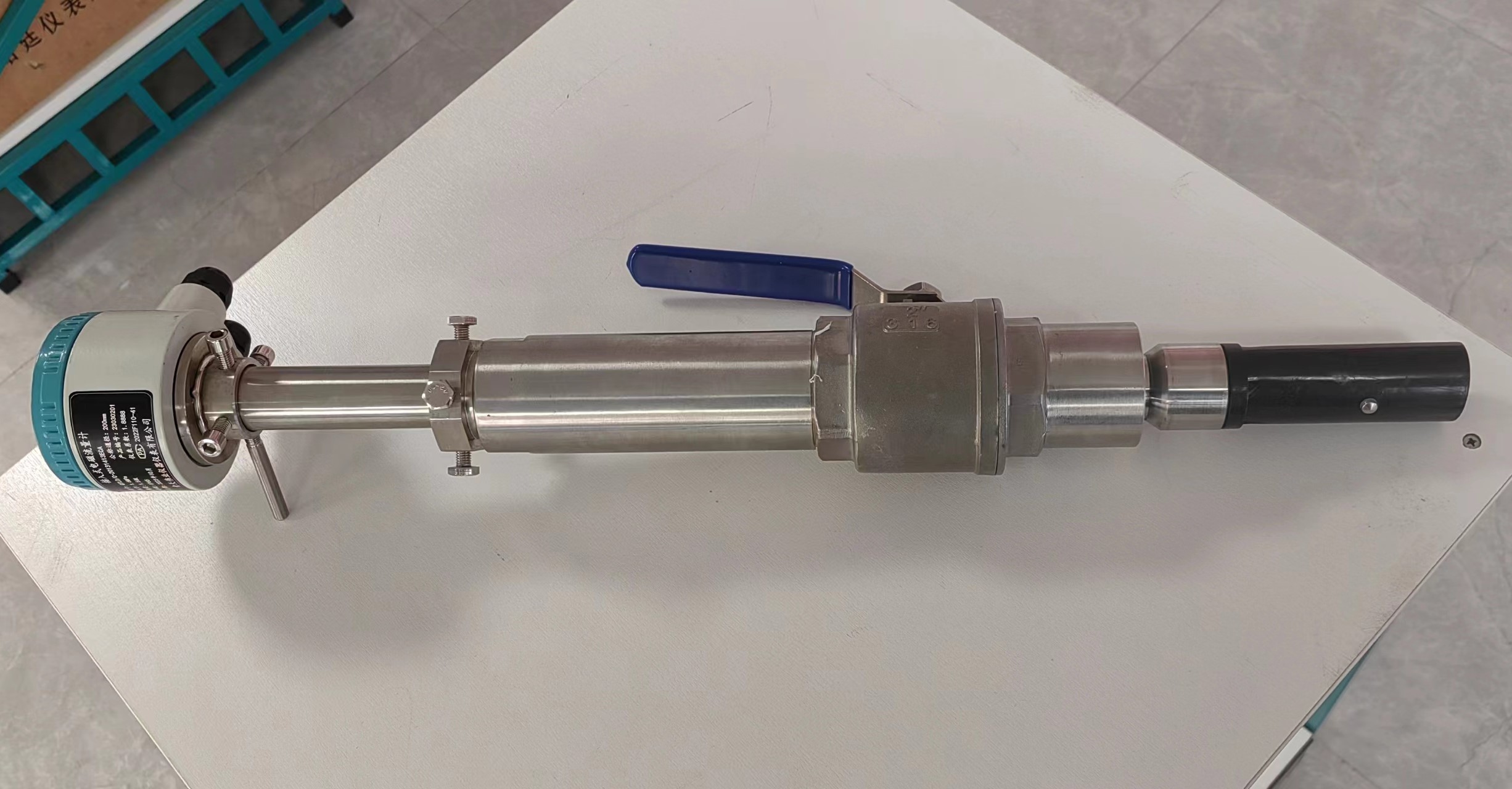

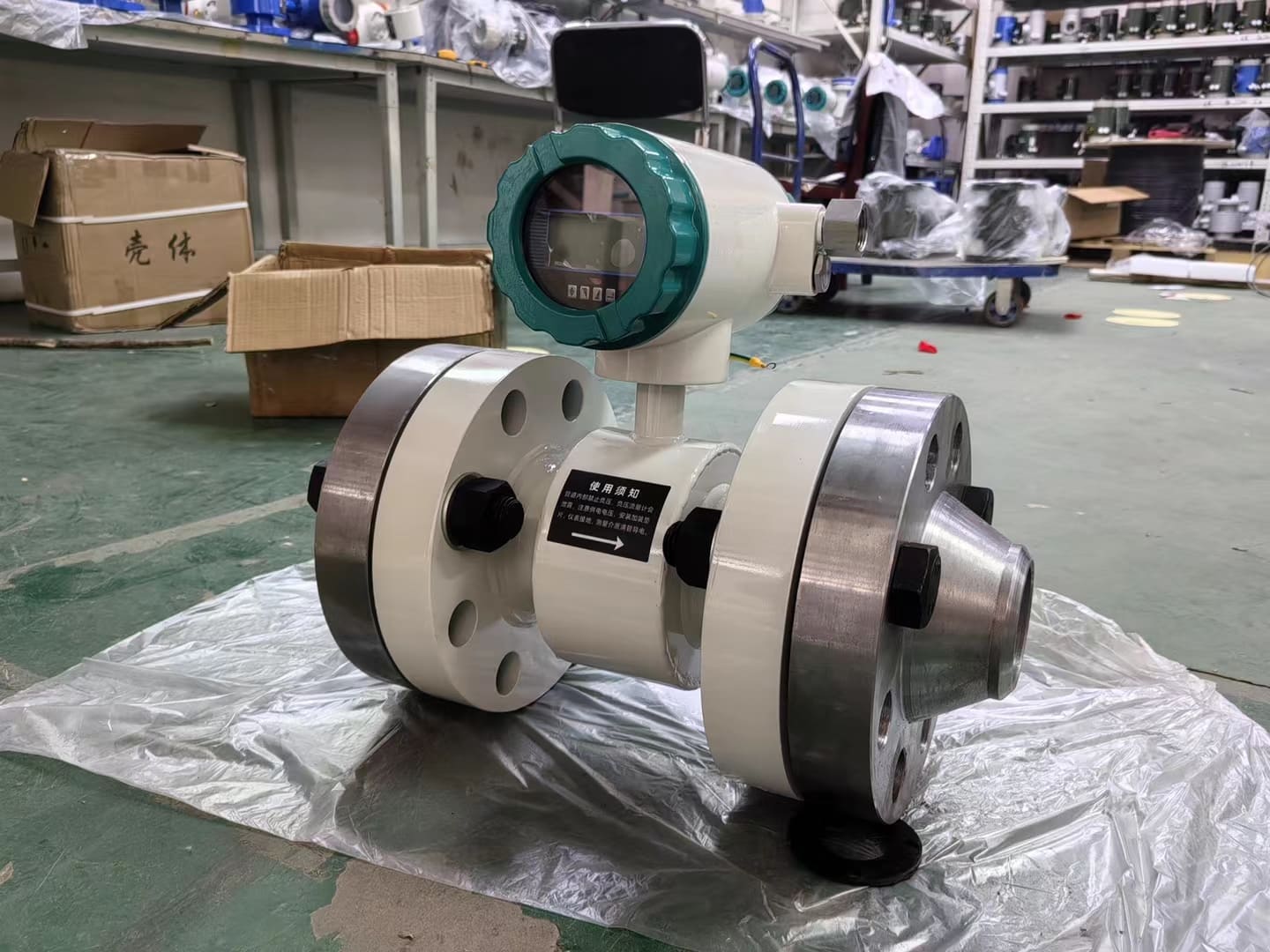

1. In addition to using a non-full tube flowmeter, ensure that the measuring pipe is filled with liquid. The transmitter should be installed where the measuring pipe can be filled with liquid at all times, and is a vertically mounted pipe with bottom-up flow of liquid to avoid measurement errors caused by sediment in the pipe or bubbles present in the medium. If the installation environment cannot carry out vertical installation of the pipe, then the two electrodes need to be installed horizontally on the same horizontal plane.

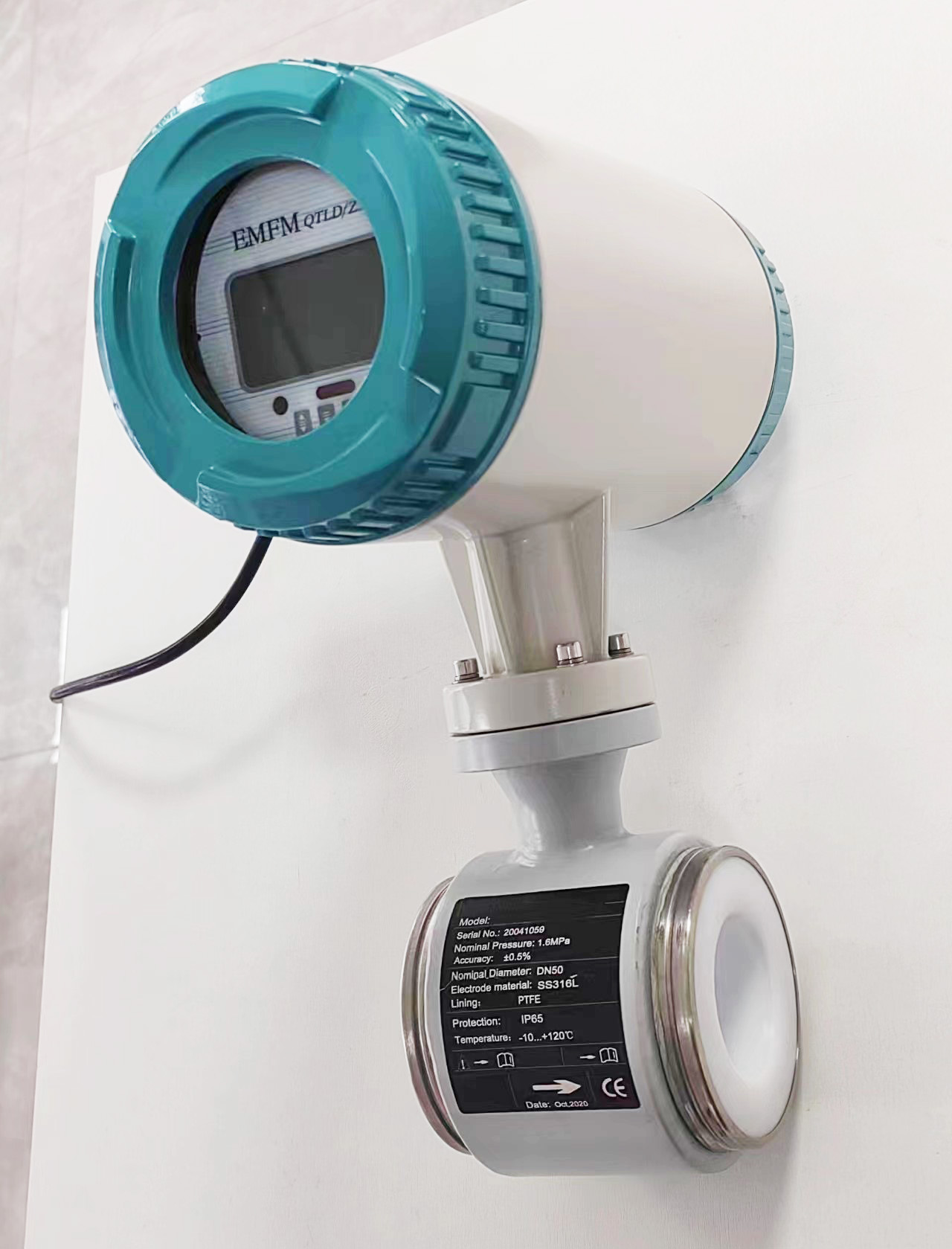

2. The measured liquid should have the conductivity required for measurement and be generally evenly distributed. Therefore, it is necessary to avoid installing the flow transmitter in a place that is prone to uneven conductivity.

3. Avoid distractions. The signal of the plug-in electromagnetic flowmeter is relatively weak, only 2.5~8mV at full scale, and the output signal is weaker when the flow rate is very small, and external interference can easily affect the measurement accuracy of the flowmeter. Therefore, the transmitter housing, shielding line, measuring pipe and the pipe at both ends of the transmitter should be grounded and set up separate ground points.

4. The converter and transmitter need to use the same phase power supply to avoid abnormal operation of the instrument caused by the phase difference between the detection signal and the feedback signal, and the transmitter should be installed away from all electromagnetic fields and vibrations.

5. To prevent the inner wall of the transmitter conduit from deposition of scale layer affecting the measurement accuracy. Too small scale resistance will lead to a short circuit of the electrode, resulting in a smaller and smaller flow signal or even a sudden decline, at the same time, the insulation lining in the catheter is damaged or the transmitter long-term in the acid, alkali and salt concentration of the site will lead to a short circuit in the measurement line of the electrode, in use should pay attention to its protection.

6. The distance between the electromagnetic flow sensor and the converter needs to be determined according to the conductivity of the measured medium and the signal cable model. In order to avoid the impact of interference signals on the measurement results, the signal cable needs to be worn separately in the grounding protection steel pipe, and the signal cable and the power cable can not be installed to the same protection steel pipe.

-.jpg)

-.jpg)