Advantages and disadvantages of sewage electromagnetic flowmeter

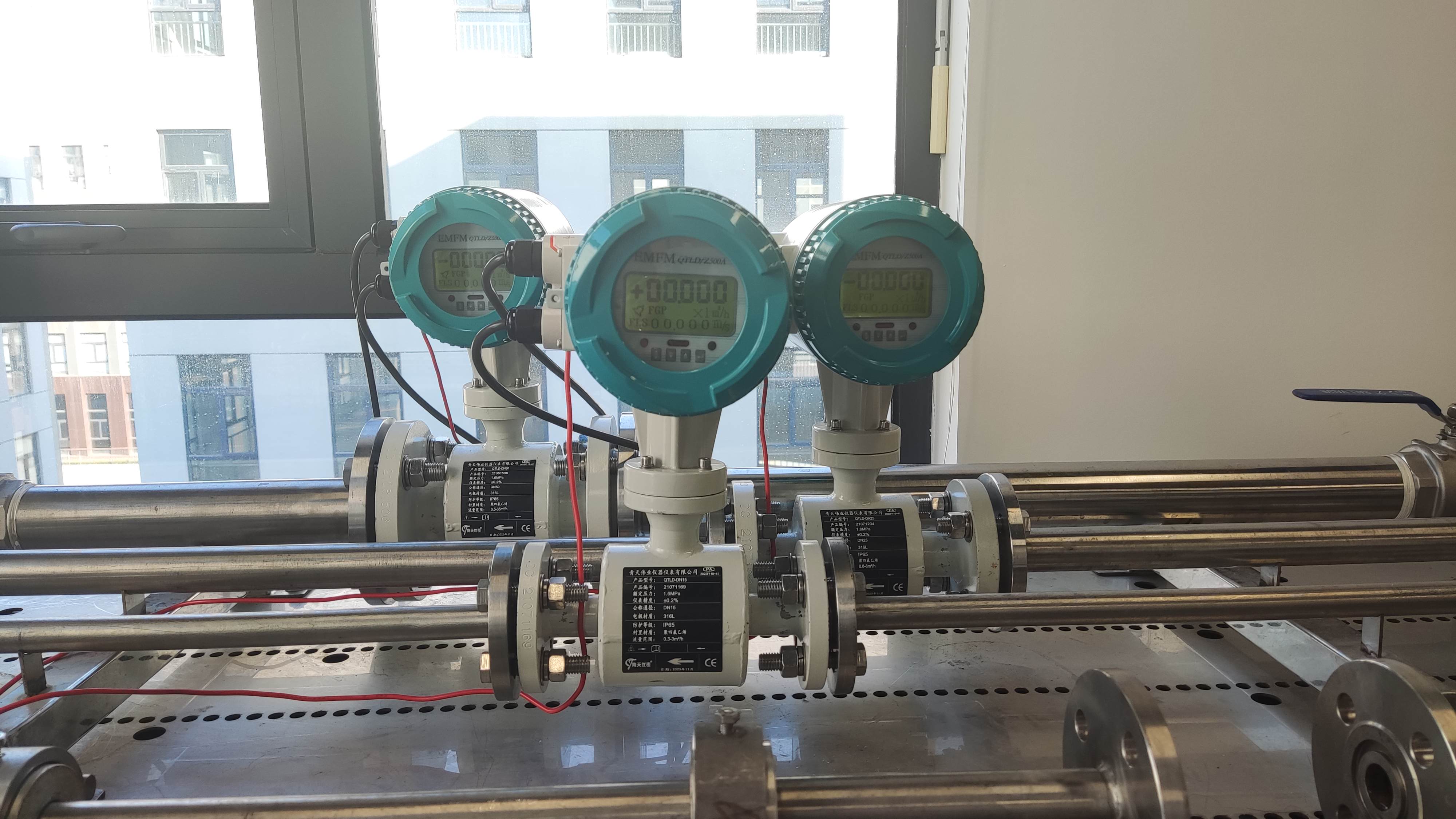

Electromagnetic flowmeter has very good characteristics, can solve other flowmeter is not easy to apply problems, such as dirty flow, corrosion flow measurement, so the application of electromagnetic flowmeter is more and more extensive. To choose a suitable electromagnetic flowmeter for yourself, you must have an understanding of it.

Advantages and disadvantages of electromagnetic flowmeter

Electromagnetic flowmeter has the following disadvantages:

1, can not measure the conductivity of very low liquid, such as oil products;

2, can not measure gas, steam and liquid containing large bubbles;

3, due to the limitations of lining materials and electrical insulation materials, general electromagnetic flowmeters are not suitable for higher temperatures;

4, the investment is relatively high, especially the measurement of large runoff.

But it is undeniable that the advantages of electromagnetic flowmeter are still more, compared with other flowmeters, electromagnetic flowmeter has the following advantages:

1, because the measurement channel is a smooth straight pipe, will not be blocked, so it is suitable for measuring liquid-solid two-phase fluids containing solid particles, such as pulp, mud, sewage, etc.;

2, no pressure loss caused by flow detection, good energy saving effect;

3, the measured volume flow rate is little affected by fluid density, viscosity, temperature, pressure and conductivity changes;

4, flow measurement range is large, optional flow range is wide;

5, can be applied to corrosive fluid flow;

7, compared with other flowmeters, electromagnetic flowmeters require a shorter straight pipe section.

-.jpg)