The importance and requirements of electromagnetic flowmeter grounding ring

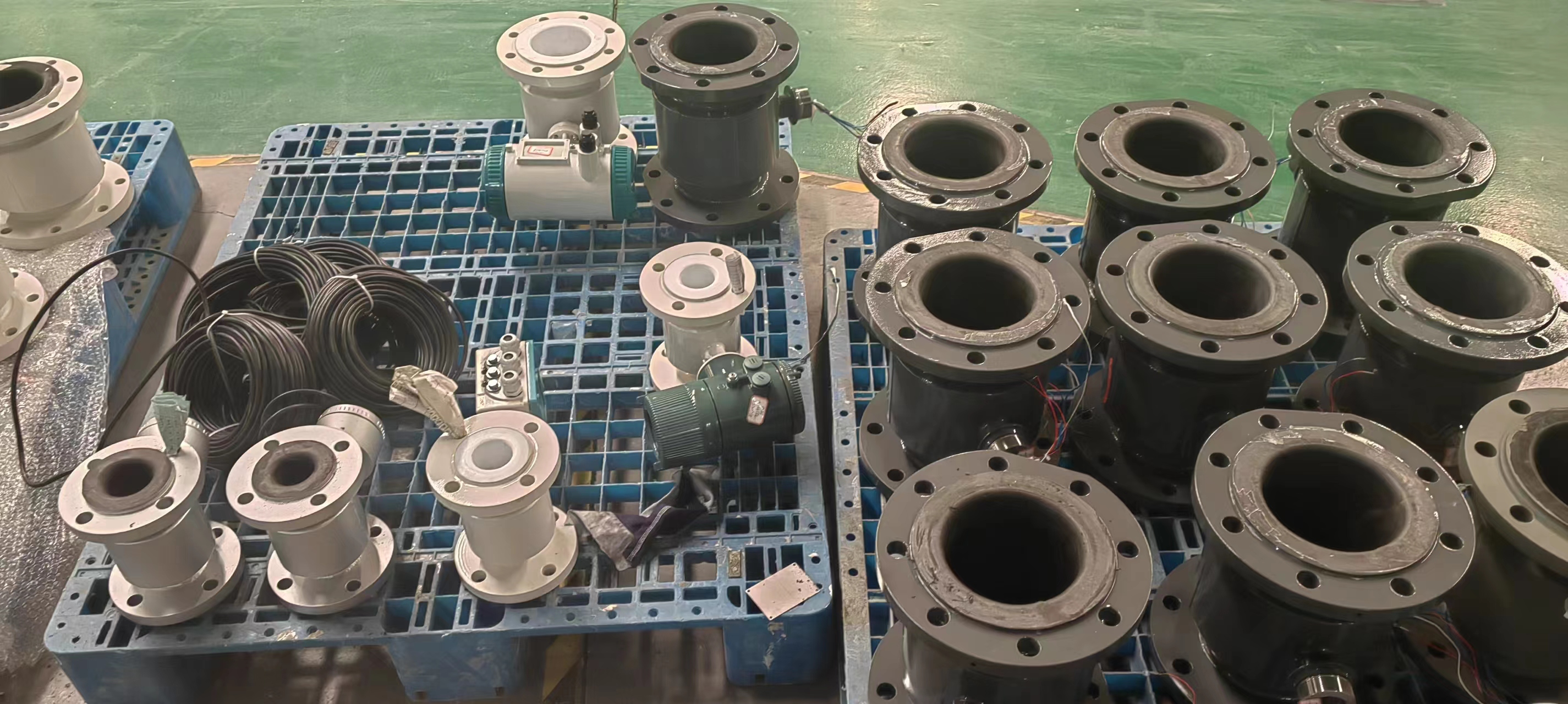

1, the role of the electromagnetic flowmeter grounding ring: the grounding ring is directly in contact with the medium through the grounding electrode, and then the grounding ring is grounded with the flange of the electromagnetic flowmeter to achieve equal potential with the ground to eliminate interference.

2, electromagnetic flowmeter grounding ring use: in some cases it is not suitable to increase the grounding ring, such as in the detection of strong corrosive media, often the pipe will use PVC or PTFE lined electrode choice is precious metal, especially for large caliber, it is impossible to match the grounding ring, the cost is too high. In this case, three electrodes are generally selected, two of which are used for measurement and one is used for grounding.

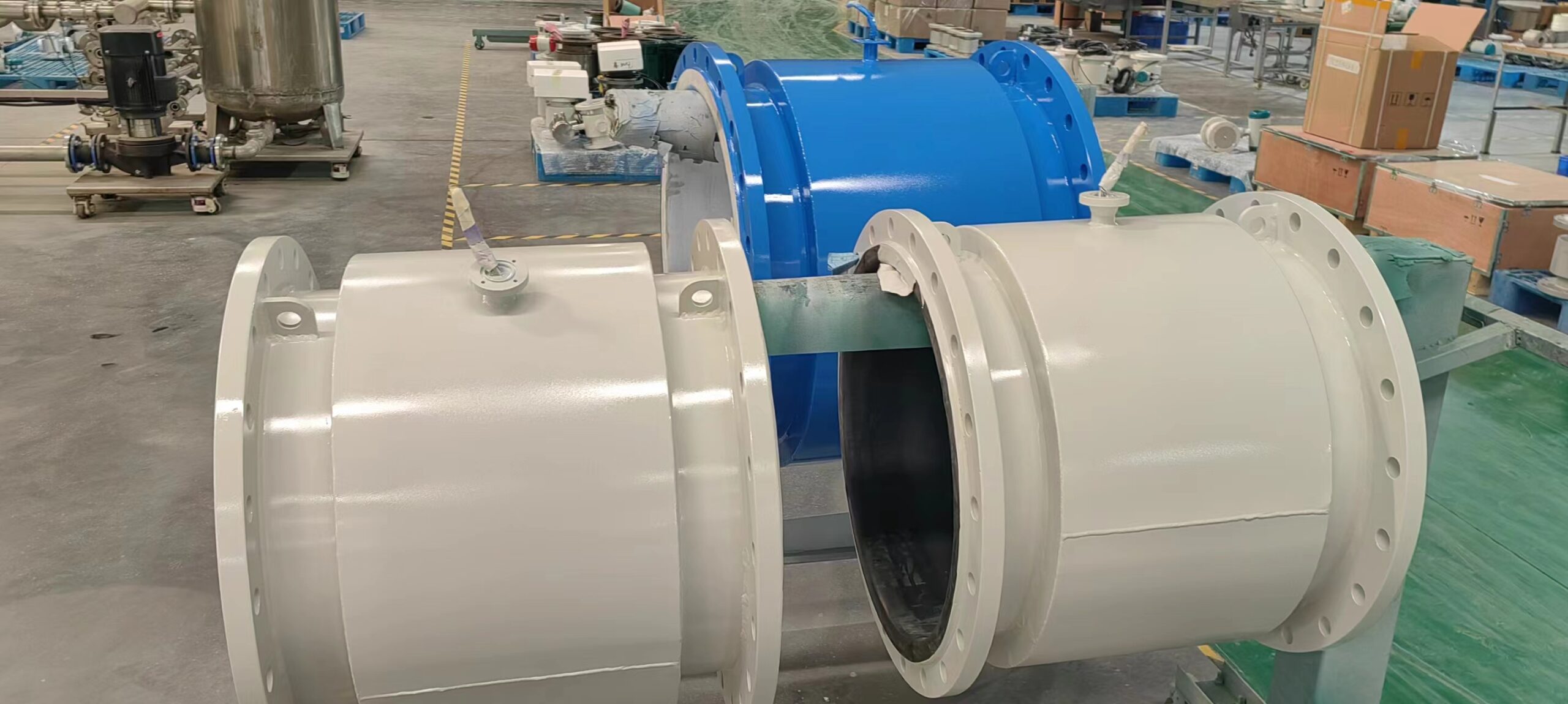

Generally, if the pipe is made of metal, it can also be without a ground ring, and the flange of the flow meter can be connected with the pipe and then grounded, which can also be used well, especially in the case of large caliber. If the small caliber, with a grounding ring does not matter, the cost will not be too bad. In addition, some users are not testing strong corrosive media, but the pipeline is non-metallic, at this time it must be equipped with a grounding ring, grounding is very important for electromagnetic flowmeters. Field magnetic field interference is fatal to electromagnetic, because the electric field we can take some means to shield, but the magnetic field we can not shield, so the installation of electromagnetic flowmeter must avoid the strong magnetic field.

Because the electromagnetic flowmeter signal is weak, only 2.5~8mv at full scale, and only a few microvolts when the flow is very small, the external interference will affect the measurement accuracy, therefore, the transmitter housing, shielding line, measuring conduit and transmitter pipeline should be grounded, and the ground point should be set separately, and must not be connected to the electric motor, electrical appliances and other public ground lines or upper and lower water pipes. The converter part has been grounded through the cable, so do not ground again to avoid interference due to different ground potential.