The correct usage method of ultrasonic level meters

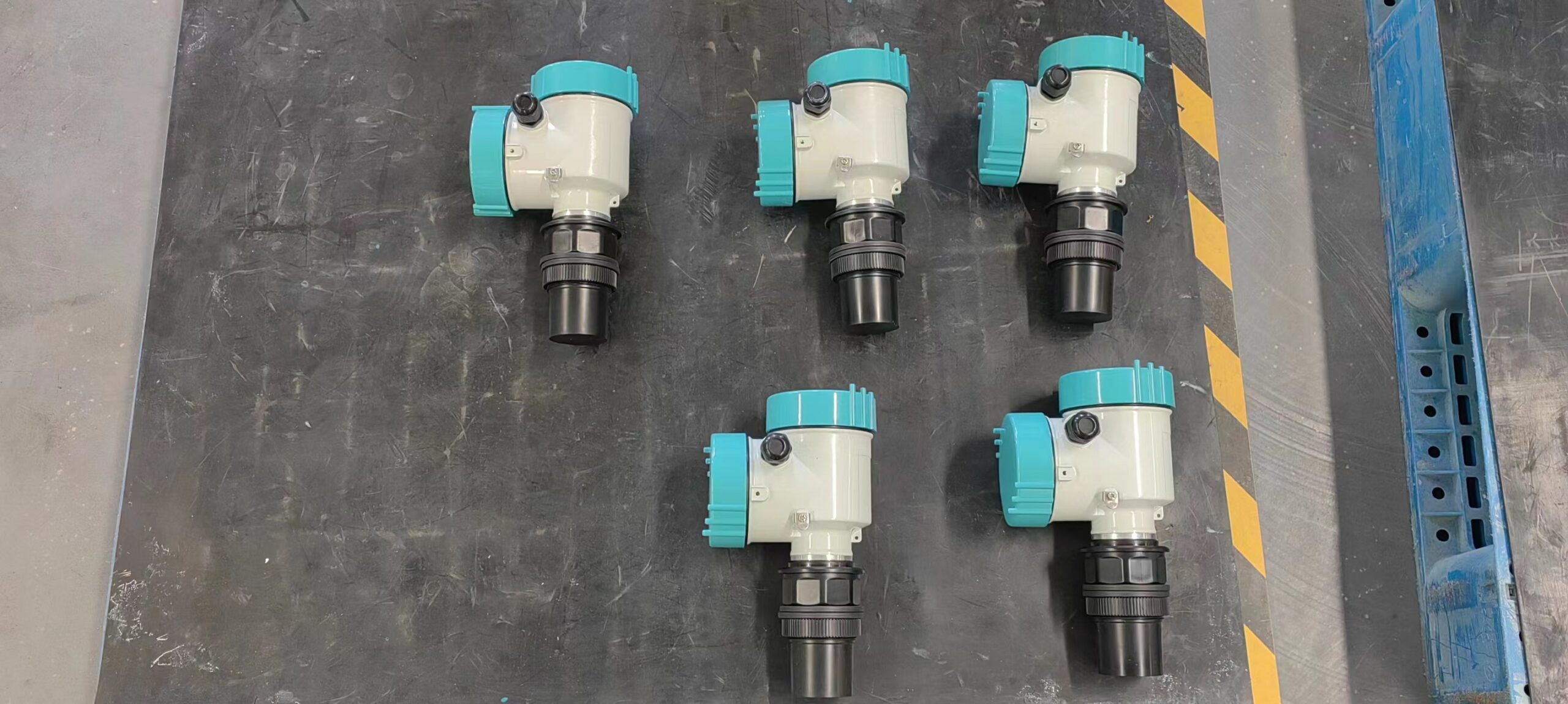

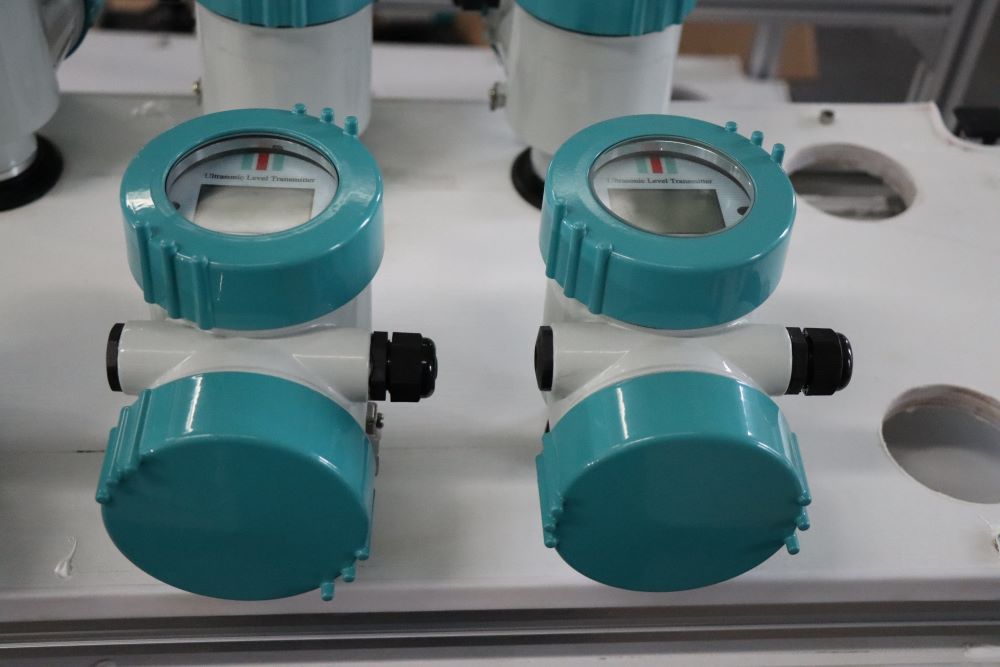

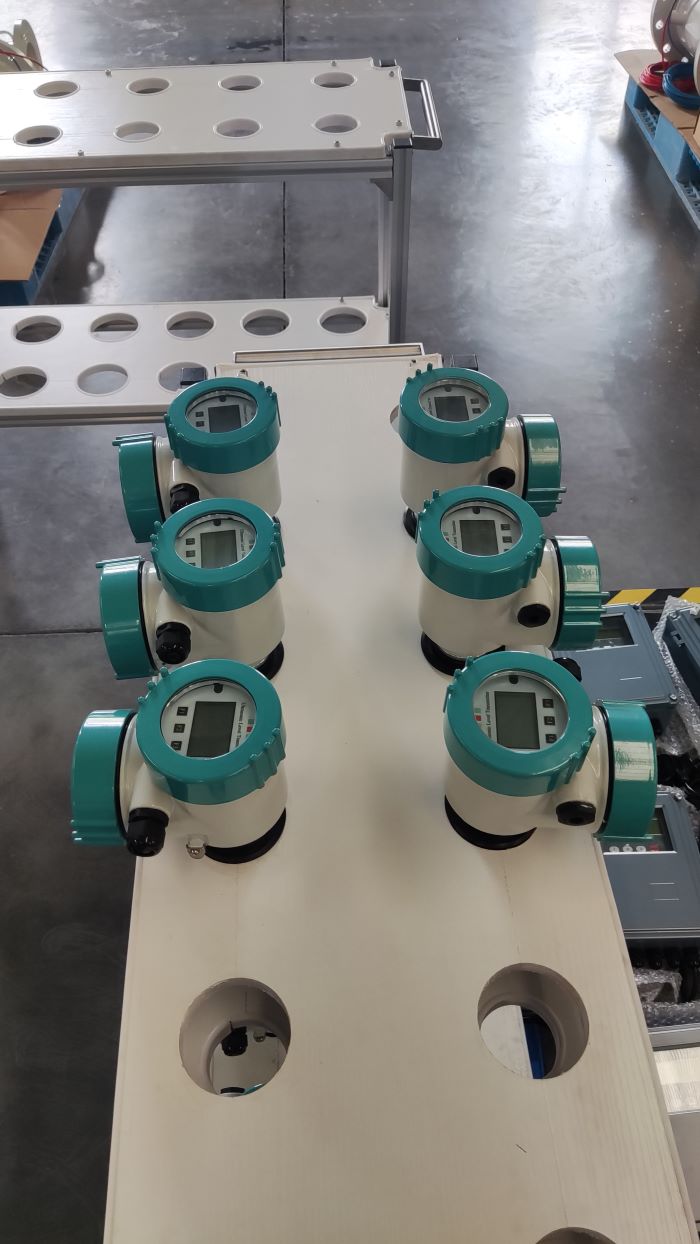

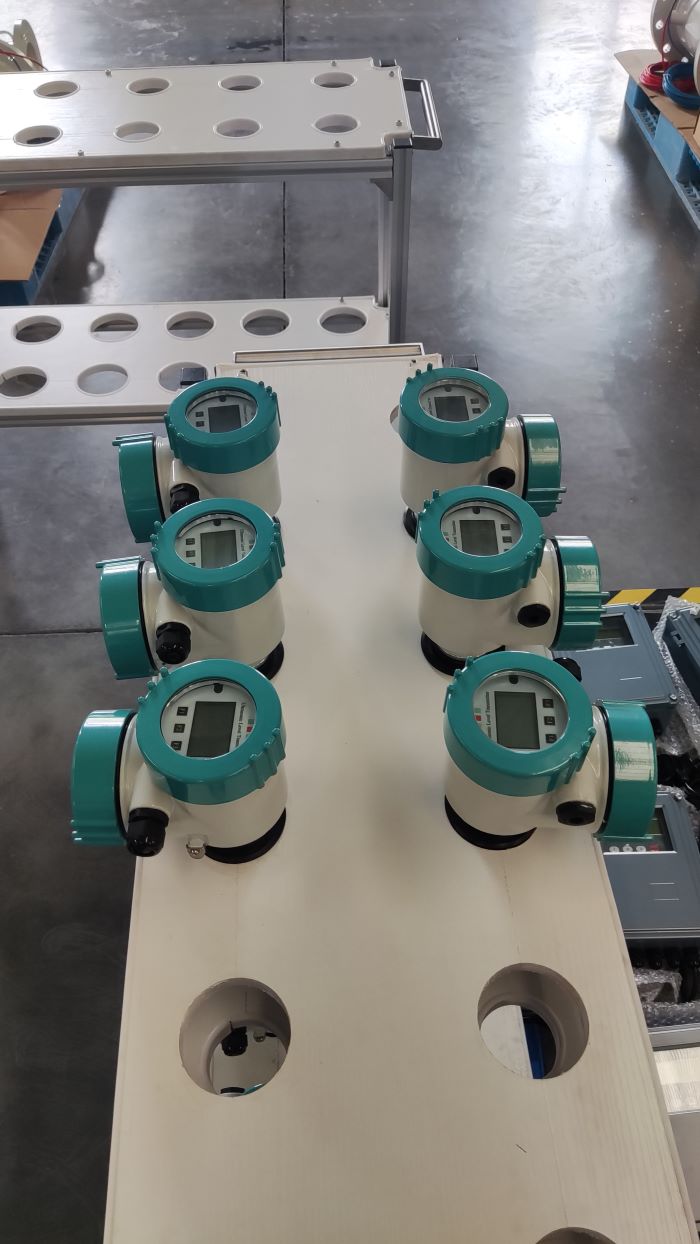

Ultrasonic level meters are widely used in the measurement of material levels in industries such as chemical engineering, water treatment, water conservancy, food, and grain. The product features safety, cleanliness, high precision, long service life, stability and reliability, convenient installation and maintenance, and simple reading. The ultrasonic level gauge is a digital level instrument controlled by a microprocessor.

In the measurement, pulsed ultrasonic waves are emitted by the sensor (transducer), and the sound waves are reflected by the surface of the object and received by the same sensor, which is then converted into an electrical signal. And the distance from the sensor to the object being measured is calculated based on the time between the emission and reception of the sound wave. Due to the non-contact measurement, the measured medium is almost unrestricted and can be widely used for the measurement of the height of various liquids and solid materials.

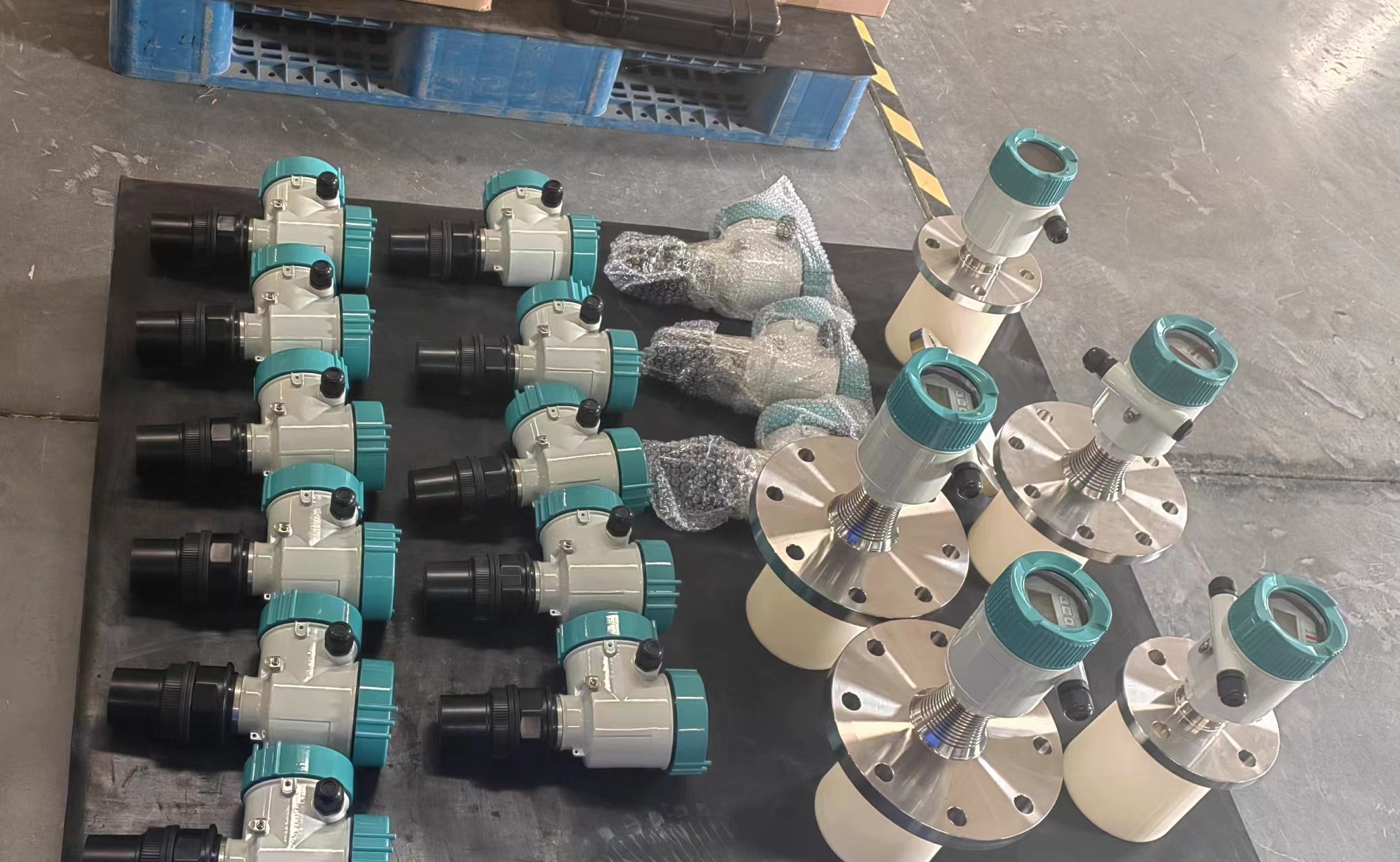

Correct use of ultrasonic level gauges

The distance from the transducer’s transmitting surface to the low liquid level should be less than the range of the selected instrument.

2. The distance from the transducer’s transmitting surface to the high liquid level should be greater than the blind zone of the selected instrument.

3. The transmitting surface of the transducer should be kept parallel to the liquid surface.

4. The installation position of the transducer should be as far away as possible from directly beneath the inlet and outlet ports and other areas where the liquid level fluctuates sharply.

5. If the pool wall or tank wall is not smooth, the instrument should be at least 0.5 meters away from the pool wall or tank wall.

6. If the distance from the transducer’s transmitting surface to the high liquid level is less than the blind zone of the selected instrument, an additional installation is required

7. Extension pipe: The extension pipe should be perpendicular to the liquid surface and its inner wall should be kept smooth.