What are the features of the clamp-on ultrasonic flowmeter

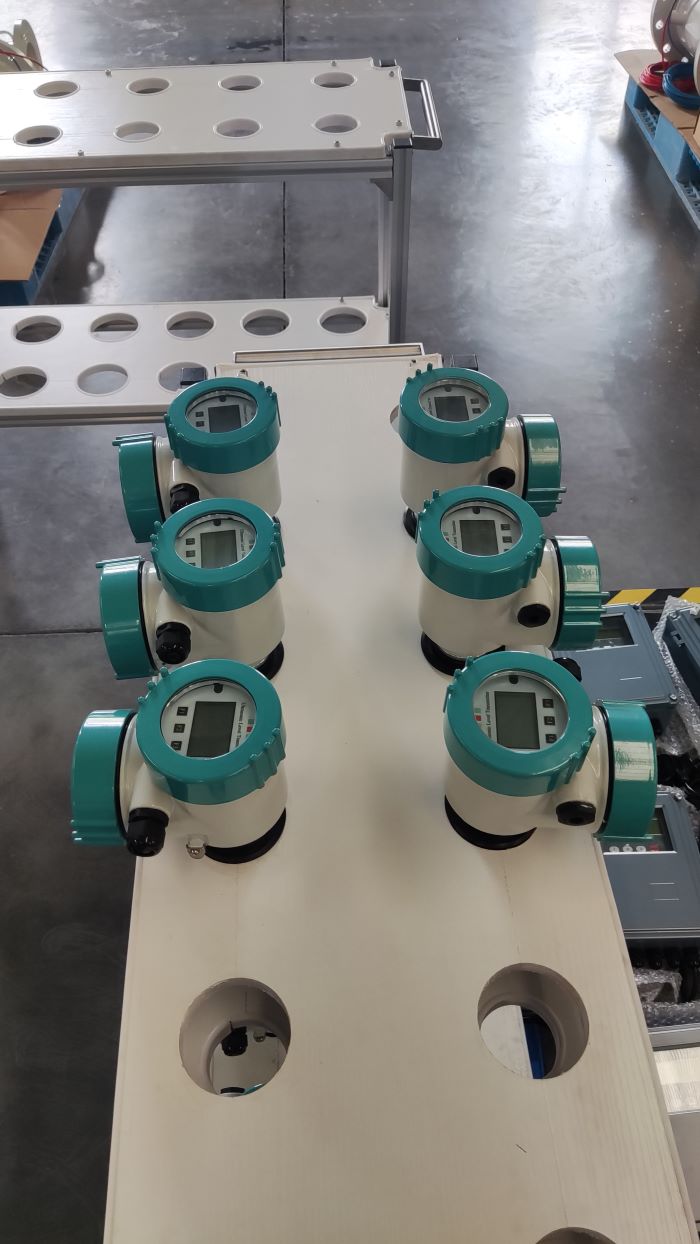

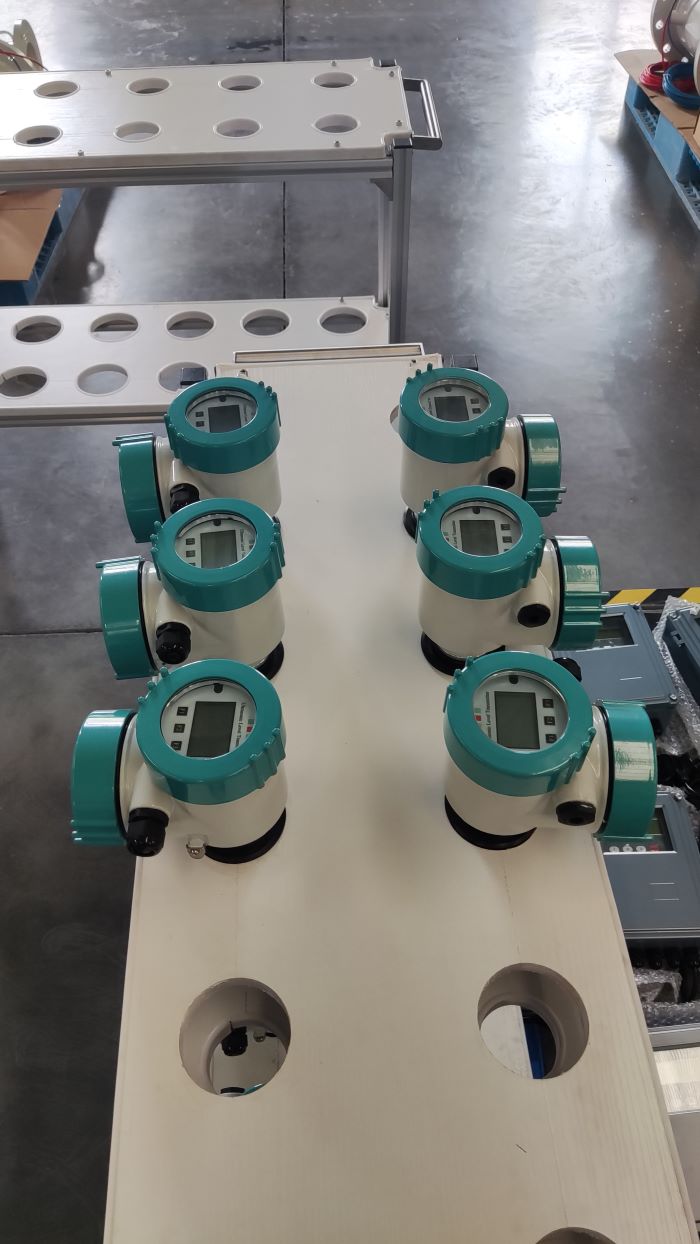

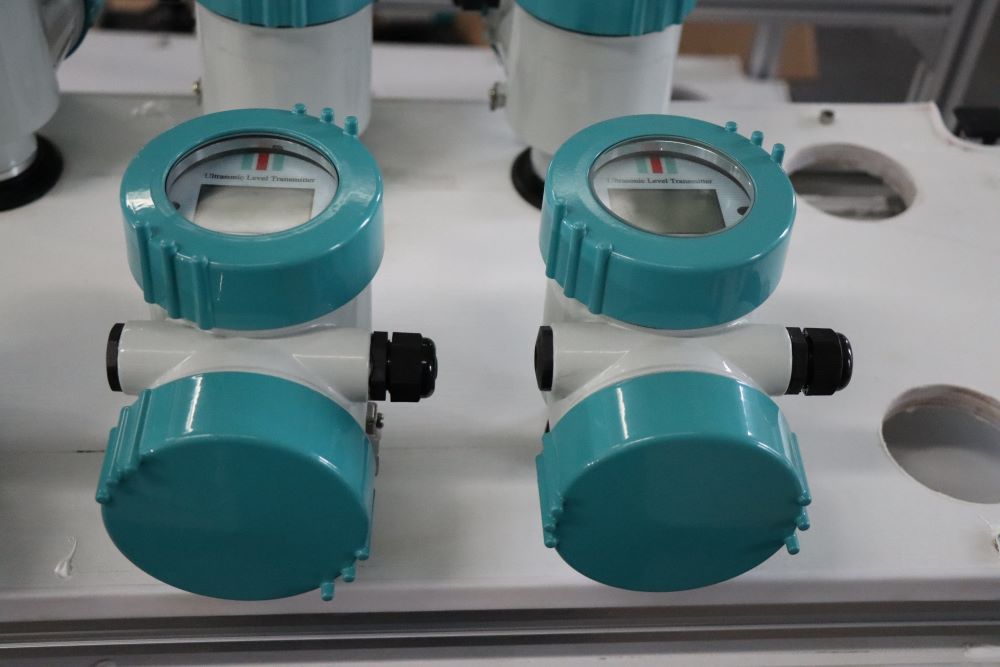

The external clamp-on ultrasonic flowmeter is composed of four parts: acoustic transducer, flow display, electronic circuit and accumulation system.

The external clamp-on ultrasonic flowmeter is composed of four parts: acoustic transducer, flow display, electronic circuit and accumulation system. The acoustic wave transmitting transducer converts electrical energy into acoustic wave energy and transmits it into the fluid to be measured. The acoustic wave signal received by the receiver is amplified by the electronic circuit and converted into an electrical signal representing the flow rate, which is supplied to the display and accumulation instrument for display and accumulation to achieve the measurement effect.

Characteristics of the external clamp-on ultrasonic flowmeter:

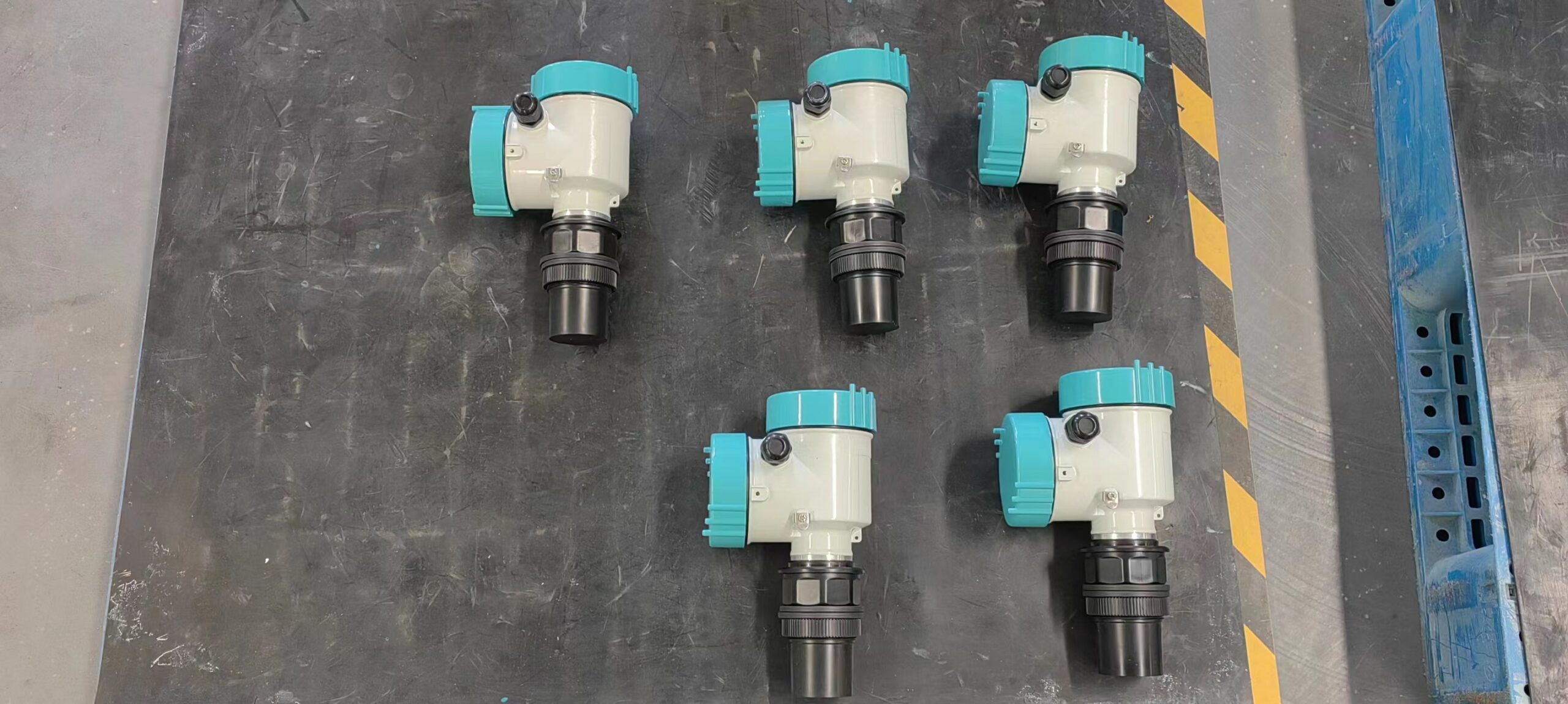

1. Easy to install

The installation of the transducer does not require the pipeline to be disconnected; it can be used immediately after being attached. This fully demonstrates the characteristics of the ultrasonic flowmeter, which is simple to install and convenient to use.

2. Less pressure loss

Pressure loss is the main problem existing in natural gas transportation. Ultrasonic flowmeters do not install components in the medium, thus not causing changes in the fluid state and generating no additional resistance. The installation and maintenance of the flowmeter will not affect the production operation. Reducing pressure loss is an ideal energy-saving flowmeter.

3. Wide application

The external clamp-on ultrasonic flowmeter has strong corrosion resistance. The measured medium fluid can also be non-conductive, and it can also solve the measurement problem of flammable and explosive media.

4. Low maintenance cost

One of the reasons for the low maintenance cost of ultrasonic flowmeters is the absence of moving parts, and the other is that they have no wear and tear themselves. We all know that some of the measured media contain impurities or dirt, which are important causes of flow and internal wear. Ultrasonic flowmeters are not worn out, so their maintenance and inspection are relatively less, and the maintenance cost is naturally lower.