What should we pay attention to when installing the steam flowmeter?

1. Requirements for piping:

The inner diameter of the upstream and downstream piping at the installation point of the steam flowmeter is the same as the inner diameter of the flowmeter.

1. Requirements for piping:

The inner diameter of the upstream and downstream piping at the installation point of the steam flowmeter is the same as the inner diameter of the flowmeter.

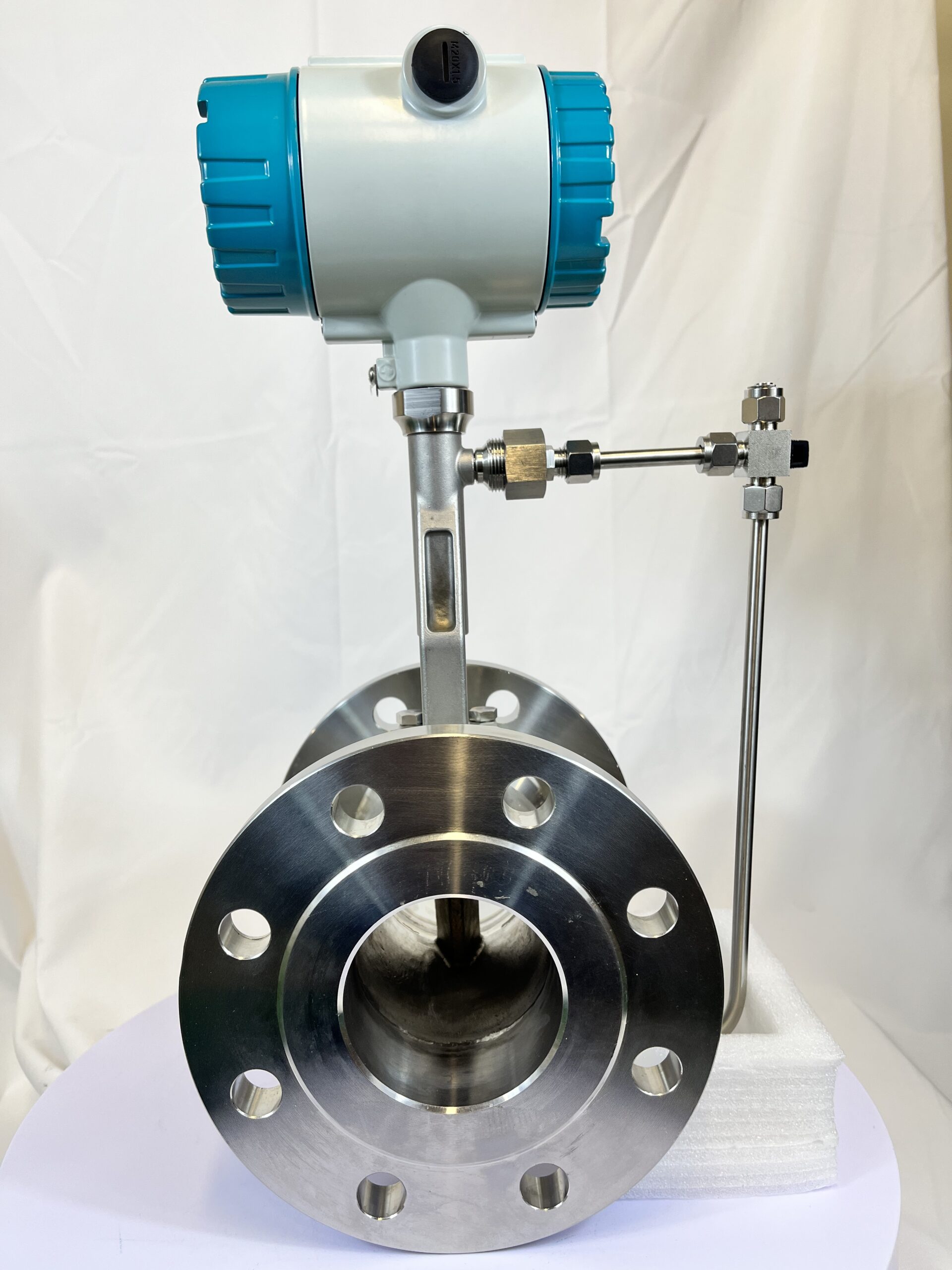

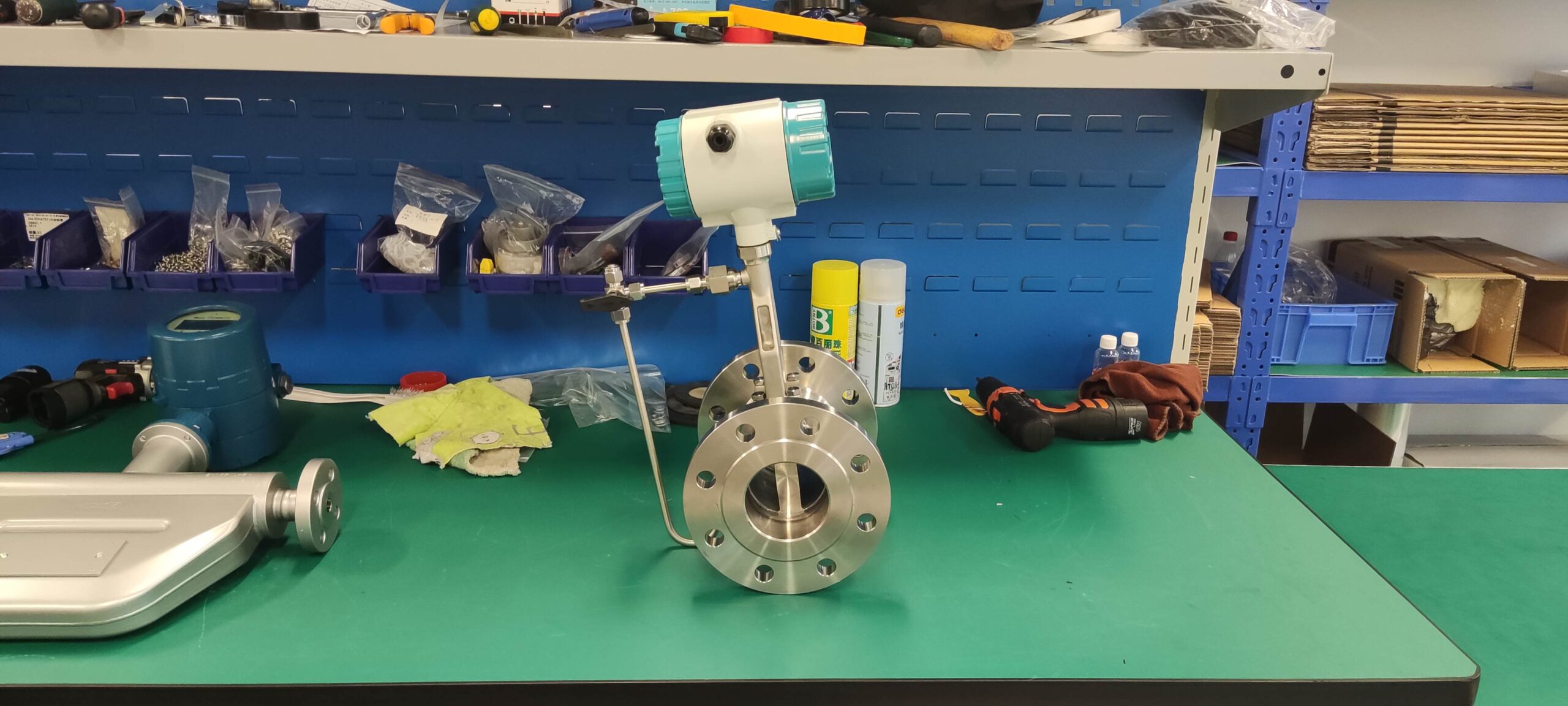

2. Requirements for straight pipe section:

a. The steam flowmeter must be installed horizontally on the pipeline (the inclination of the pipeline is within 5), and the flowmeter axis is concentric with the pipeline axis when installed, and the flow direction should be consistent.

b. The length of the upstream pipe of the flowmeter should be less than 10D of the equal straight pipe section, if the installation site allows it is recommended that the upstream straight pipe section is 20D and the downstream is 5D.

3. Requirements for bypass pipes:

In order to ensure that the normal use of the medium is not affected during the maintenance of the steam flowmeter, a cut-off valve (stop valve) should be installed on the front and back pipes of the flowmeter, and a by-pass pipe should be set up. The flow control valve should be installed in the downstream of the flow meter, and the stop valve installed in the upstream when the flow meter is used must be fully opened to avoid the unsteady flow of the upstream part of the fluid.

4. Installation site:

The steam flowmeter should be installed in a place that is easy to maintain and free from strong electromagnetic interference and thermal radiation.

5. Requirements for external environment:

When the steam flowmeter is installed indoors and must be installed outdoors, it must use sun protection, rain protection and lightning protection measures to avoid affecting the service life.

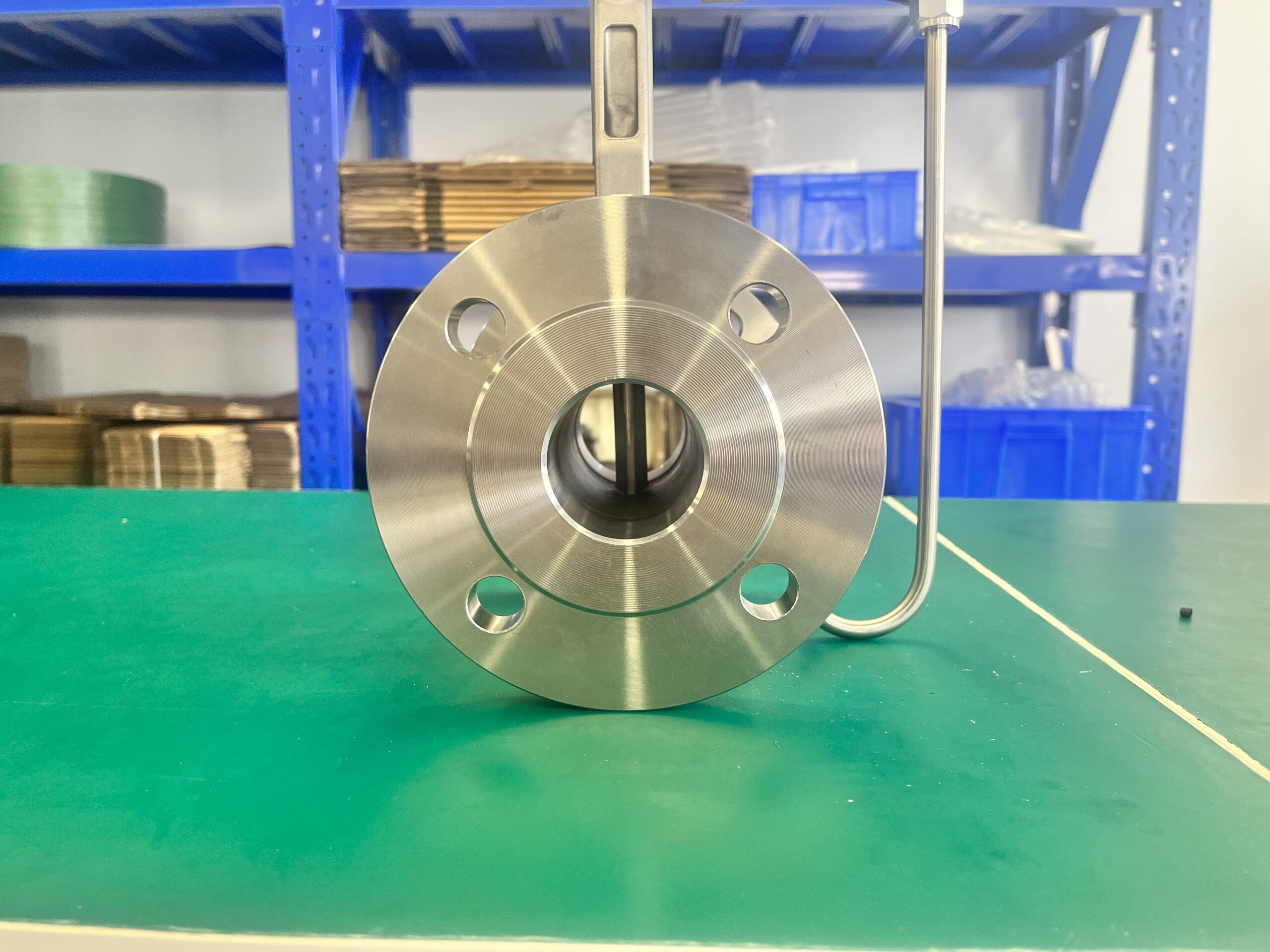

6. Weld the installation

a. The user configures another pair of standard flanges to be welded on the front and rear pipes. Welding with steam flowmeter is not allowed;

b. Before installing the steam flowmeter, the pipe should be cleaned of debris: debris, welding slag, stone, dust, etc. It is recommended to install a filter with a 5μm screen in the upstream to block droplets and sand. Use an equal diameter pipe (or bypass pipe) instead of a flowmeter to purge the pipe. To ensure that the flow meter is not damaged during use.

c. Install the steam flowmeter. The sealing gasket between the flanges should not be concave into the pipe to prevent interference with normal flow measurement.