Analysis of the Application Limitations of Insertable Vortex Flowmeters

Insertable vortex flowmeters are widely used in the measurement of steam, gas and liquid flow due to their advantages such as simple structure, easy installation and low cost. However, in practical applications, its measurement performance is limited by multiple factors. If the selection or use is improper, it may lead to data deviation or even equipment damage. This article will conduct an in-depth analysis of the main limitations of the insertable vortex flowmeter to help users make reasonable selections and optimize their usage.

1. Medium adaptability limitations

Vortex flowmeters operate based on the Karman vortex street principle and are relatively sensitive to the characteristics of the medium. They have the following limitations:

Only applicable to single-phase fluids: If the medium contains bubbles (liquids) or droplets (gases), the vortex street shedding frequency will be interfered with, resulting in measurement errors.

Measurement of low-density media is difficult: For low-pressure gases (such as air and natural gas), the signal is weak when the flow rate is too low, and stable detection may not be possible.

Not suitable for high-viscosity liquids: such as heavy oil, mud, etc. High viscosity will inhibit the formation of vortex streets and affect the measurement accuracy.

2. The installation conditions are strictly required

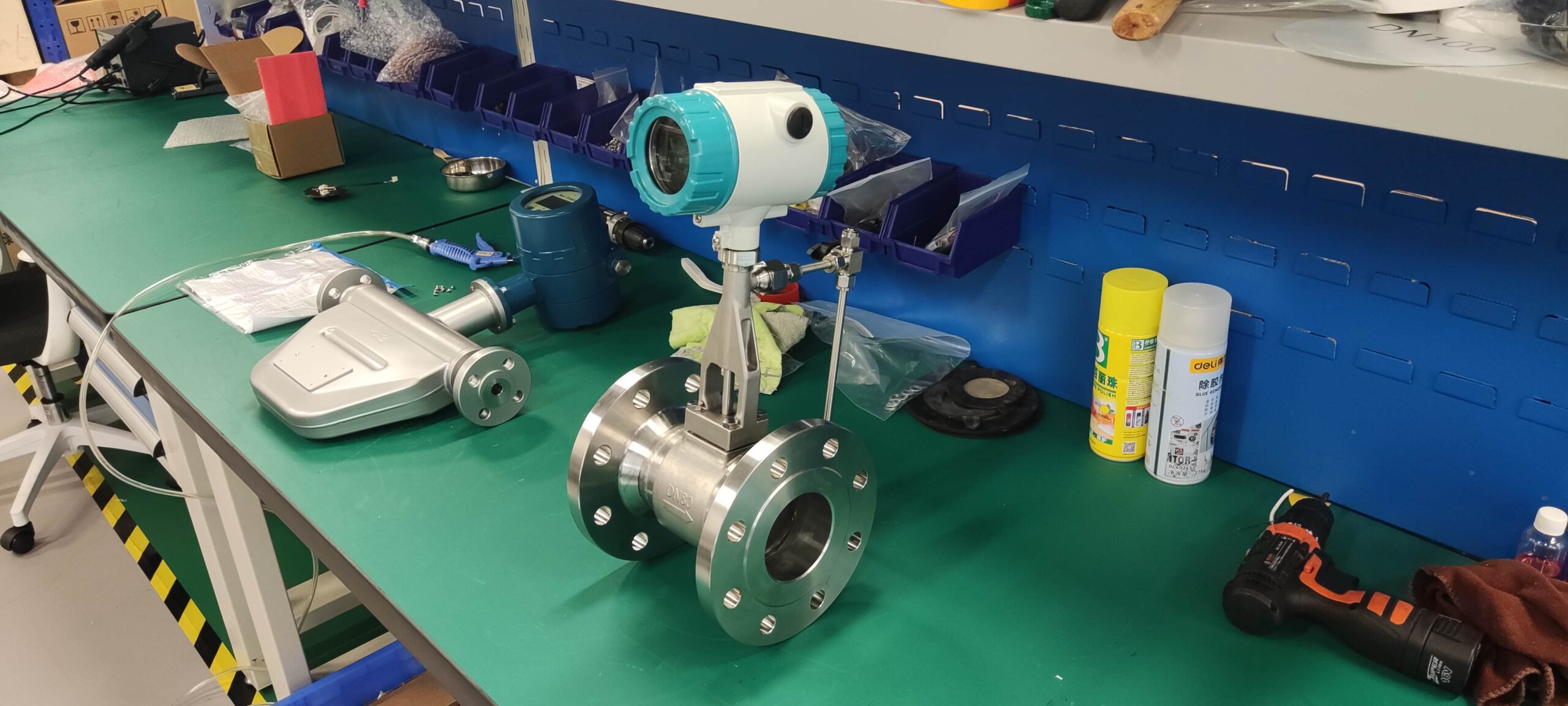

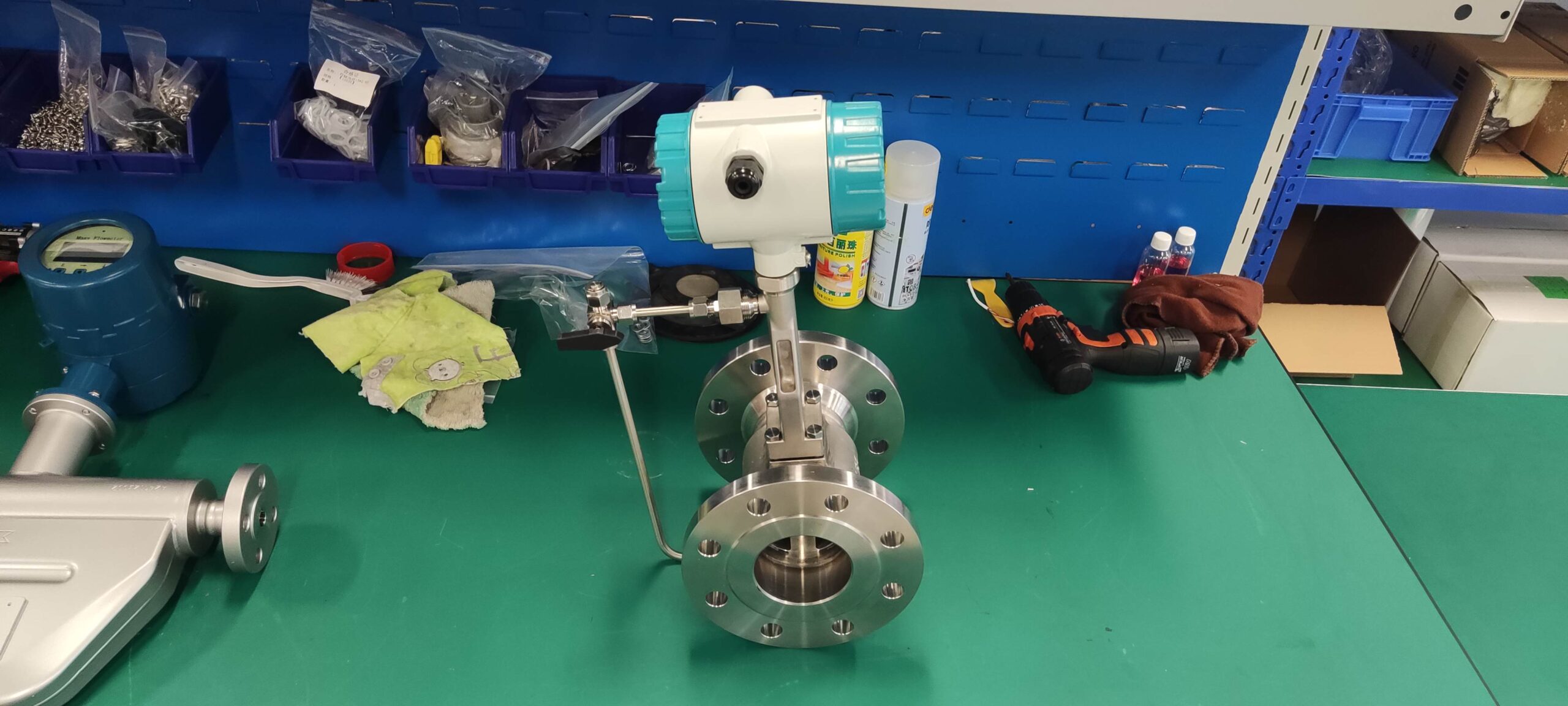

The measurement accuracy of the insertable vortex flowmeter is significantly affected by the flow state of the pipeline. Improper installation can easily lead to large errors:

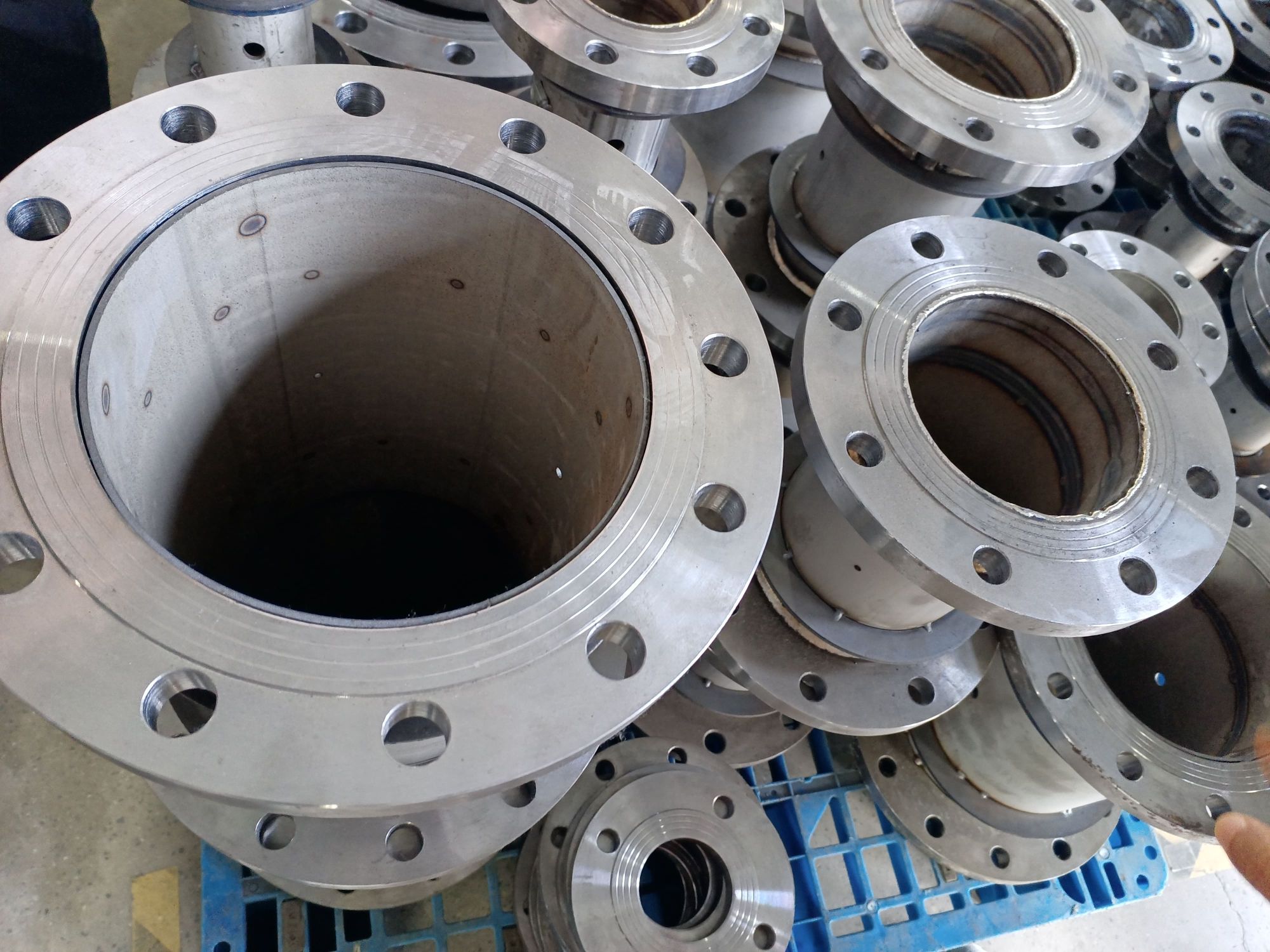

High requirements for straight pipe sections: To ensure stable flow conditions, at least 15D (D being the pipe diameter) of straight pipe sections are needed upstream and 5D downstream. If there are pumps, valves or elbows nearby, the sections need to be further extended.

Vibration interference sensitivity: Mechanical vibration may cause false vortex street signals. It should be avoided to be installed near vibration sources such as compressors and fans, or shock absorption devices should be added.

Insertion depth affects accuracy: The probe must be located at the flow velocity of the pipe (usually at the position of 1/8 to 1/4 of the pipe diameter). Excessive deviation will lead to a decrease in linearity.

3. Range ratio and accuracy limitations

Limited range ratio: The range ratio of a common vortex flowmeter is usually 10:1, which is much lower than that of electromagnetic or ultrasonic flowmeters (up to 100:1). Under conditions with large flow fluctuations, it is prone to small signal cut-off or over-range problems.

Poor accuracy at low flow rates: When the flow rate is lower than 0.5m/s (for liquids) or 5m/s (for gases), the vortex street signal is weak and the measurement error increases significantly.

4. Maintenance and lifespan issues

The probe is prone to clogging or wear: Media containing particles or fibers (such as sewage, steam with impurities) may clog the probe or cause mechanical wear, and regular cleaning is required.

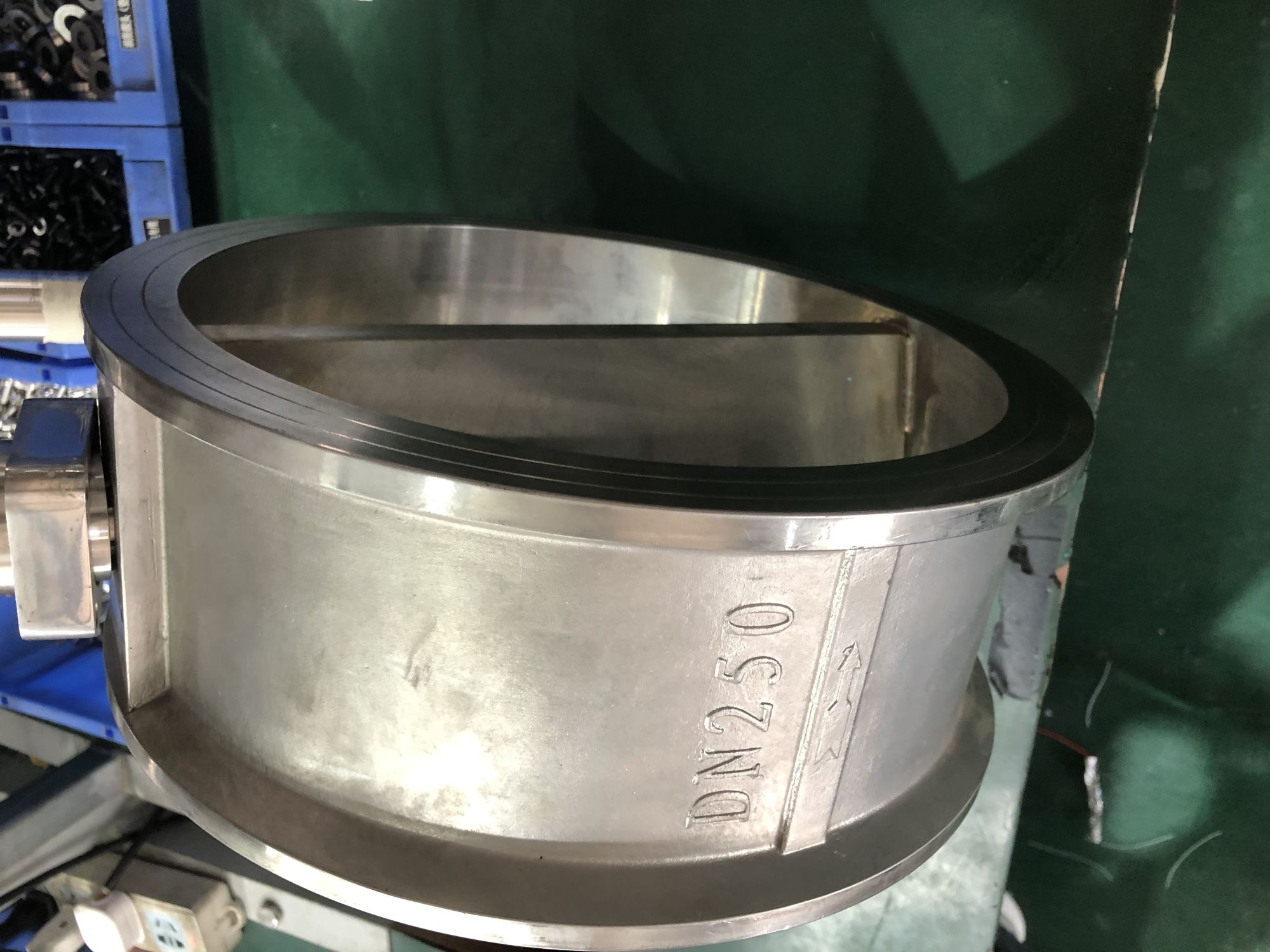

Limitations in high-temperature and high-pressure working conditions: When used for a long time in high-temperature steam (> 250℃) or high-pressure pipelines, the sealing parts and probe materials may age, shortening their service life.

5. Suggestions for applicable scenarios

Despite its limitations, the insertable vortex flowmeter is still applicable to the following scenarios:

Clean steam metering (such as boiler steam, heating network);

Measurement of medium and high-pressure gases such as compressed air and nitrogen;

Stable flow monitoring of low-viscosity liquids (water, light oil).