What causes the inner lining of an electromagnetic flowmeter to deform

After being used for a period of time, electromagnetic flowmeters sometimes experience lining deformation, which can lead to inaccurate measurements or sensor damage. Lining deformation mostly occurs in fluoroplastic linings. The common causes are generally two types:

The vapor penetration within the medium causes the fluoroplastic lining to undergo thermal diffusion. Thermal diffusion refers to the natural physical phenomenon that occurs when the medium (containing gas or vapor) in the pipeline flows through the fluoroplastic lining. The degree of penetration usually mainly depends on multiple factors such as the lining material, the type of liquid and vapor, the thickness of the lining (the thickness of the lining is inversely proportional to the degree of penetration), the temperature difference between the inside and outside of the lining (the temperature difference between the inside and outside of the lining is directly proportional to the degree of penetration), and the pipe pressure.

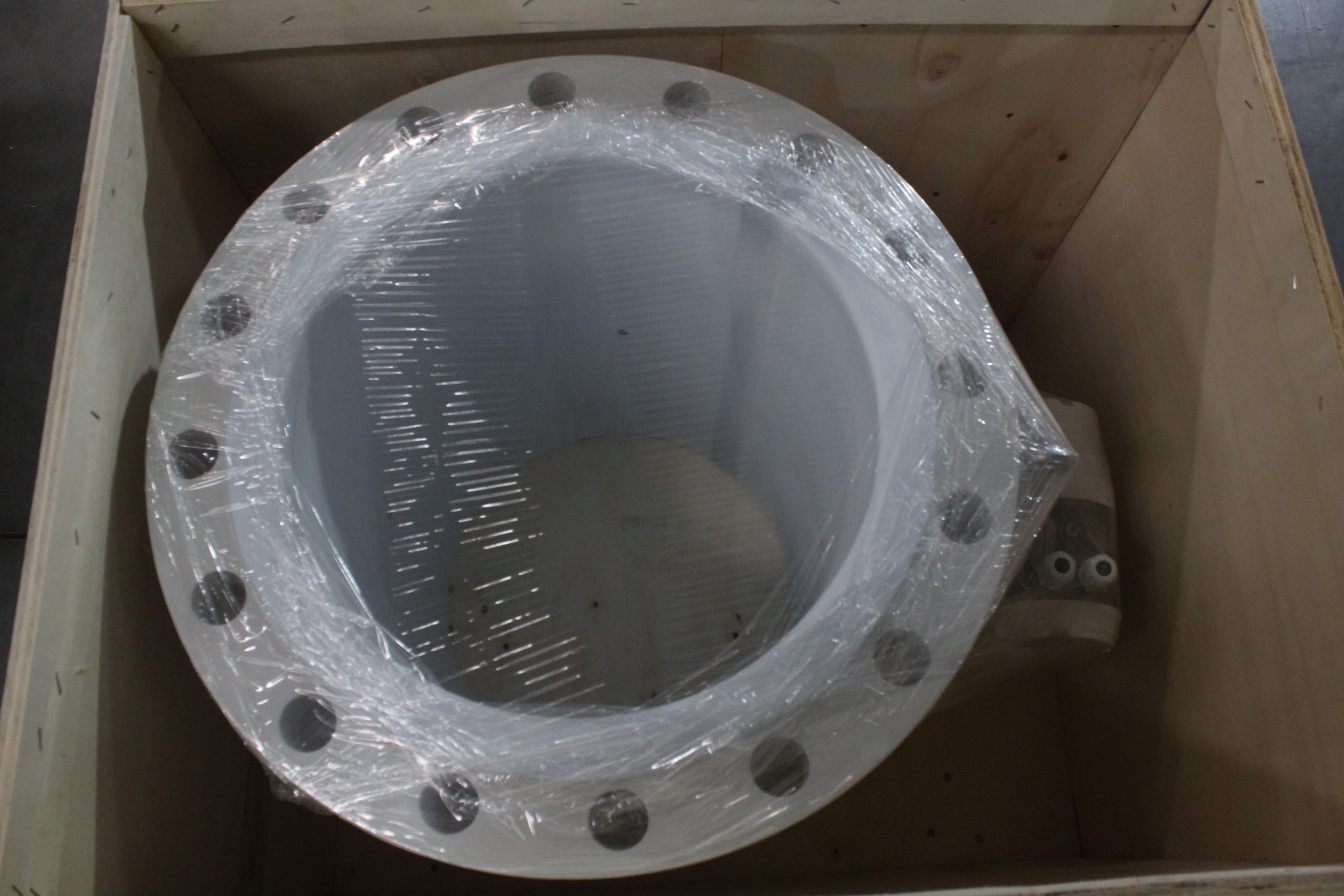

2. Due to the inherent process structure of fluoroplastic linings, especially polytetrafluoroethylene (PTFE) linings, since PTFE and the pipe wall are often only pressed together without adhesion, they cannot be used in negative pressure pipelines. However, in high-temperature applications, the instantaneous formation of negative pressure in the pipeline often leads to the deformation of the lining.

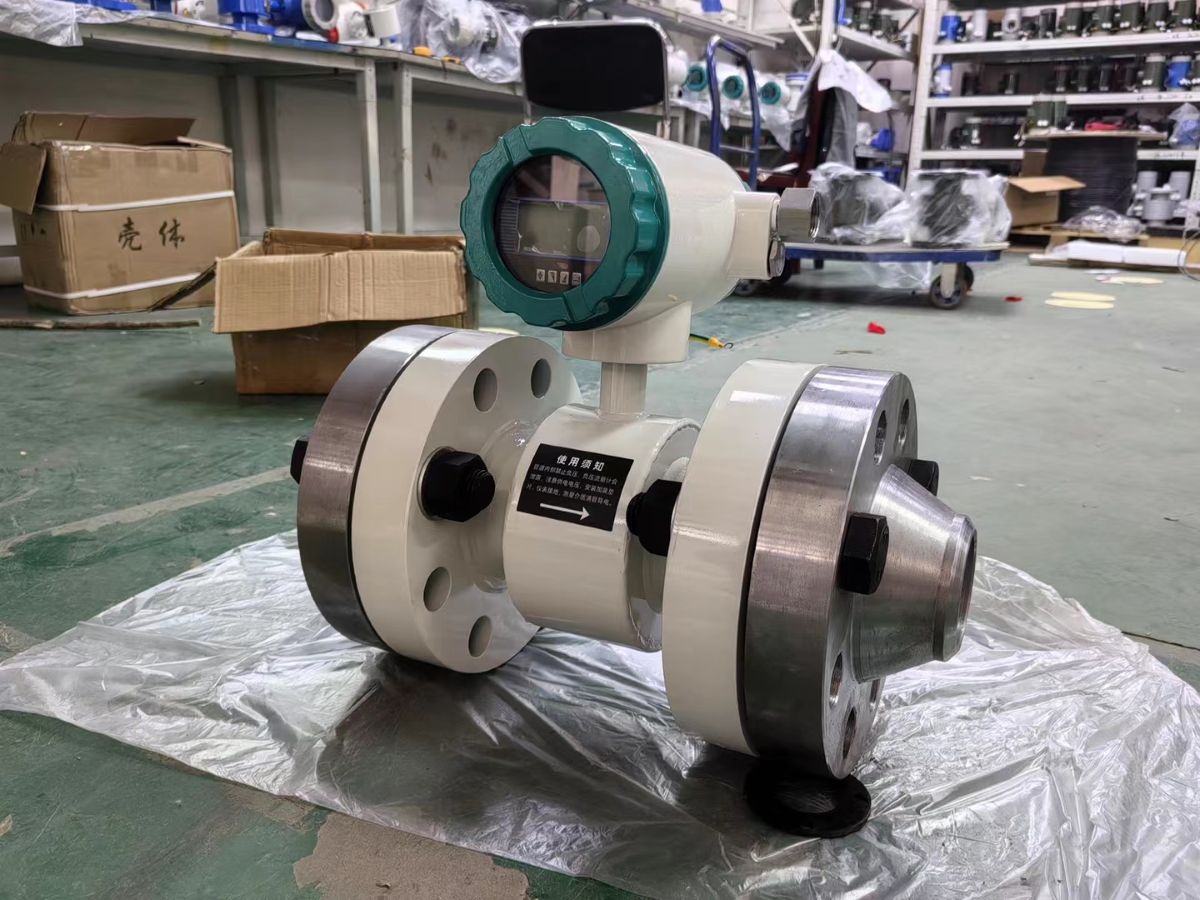

Lining deformation is generally not directly detectable on site. Currently, the commonly used method for judgment can only be to remove the sensor of the electromagnetic flowmeter from the process pipeline and observe it with the naked eye when a large flow error is found in the actual application process. There are no other effective methods in the industry for the time being.

How to solve the deformation of the lining of an electromagnetic flowmeter?

As mentioned earlier, the temperature difference between the inside and outside of the lining is directly proportional to the degree of permeability. Therefore, heat insulation measures are added between the flange and the coil box of the flowmeter to reduce the temperature difference and heat diffusion. This will greatly improve the temperature difference between the inside and outside of the lining, thereby helping to reduce the permeability and the condensation of steam within the measuring tube wall.

Thicken the thickness of the polytetrafluoroethylene (PTFE) lining of the electromagnetic flowmeter;

Under the premise of not affecting the anti-corrosion and temperature resistance of the electromagnetic flowmeter, other types of linings, such as PFA and ceramic linings, should be adopted.

-.jpg)