The applications of electromagnetic flowmeters of different classifications in various fields

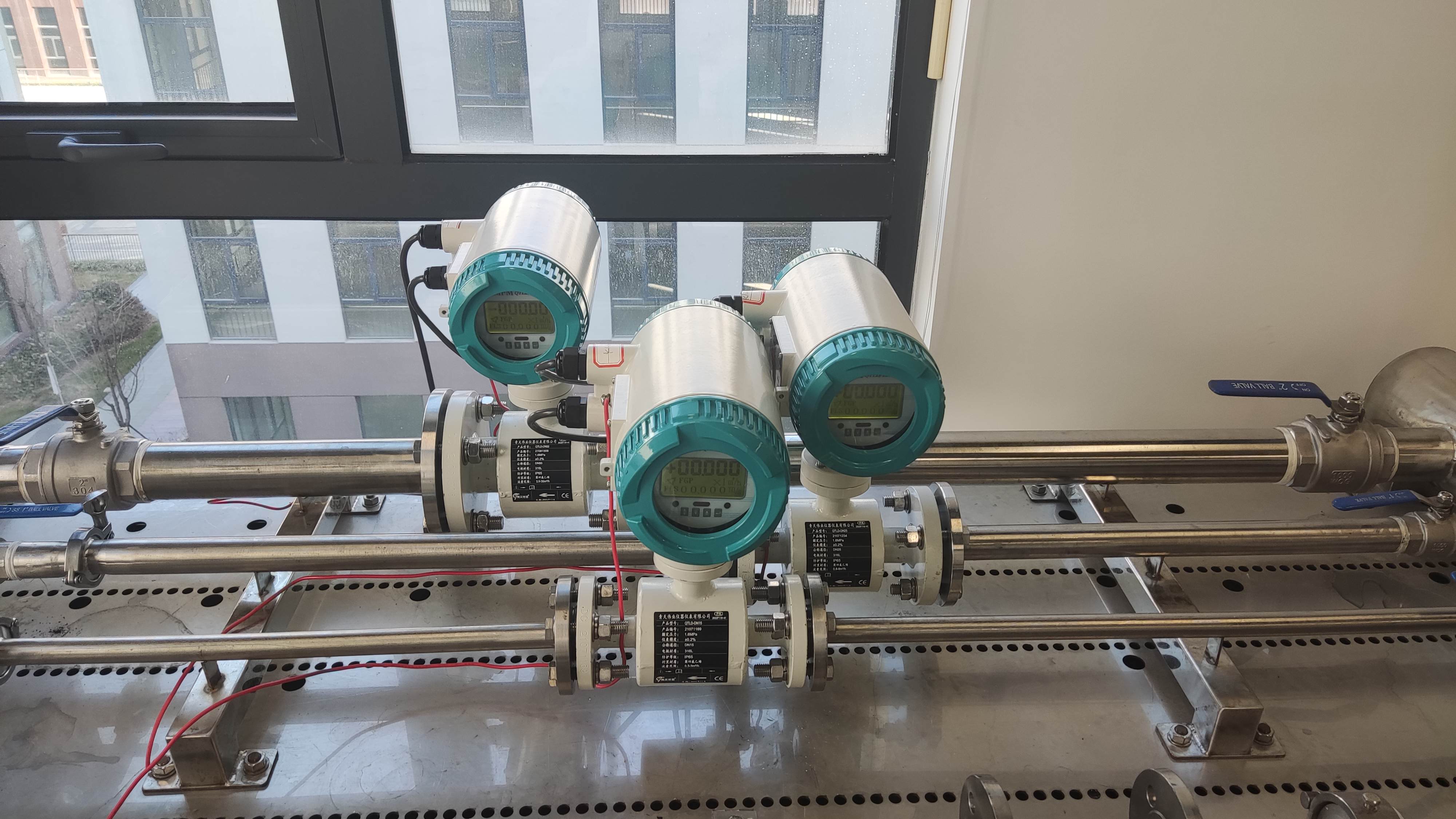

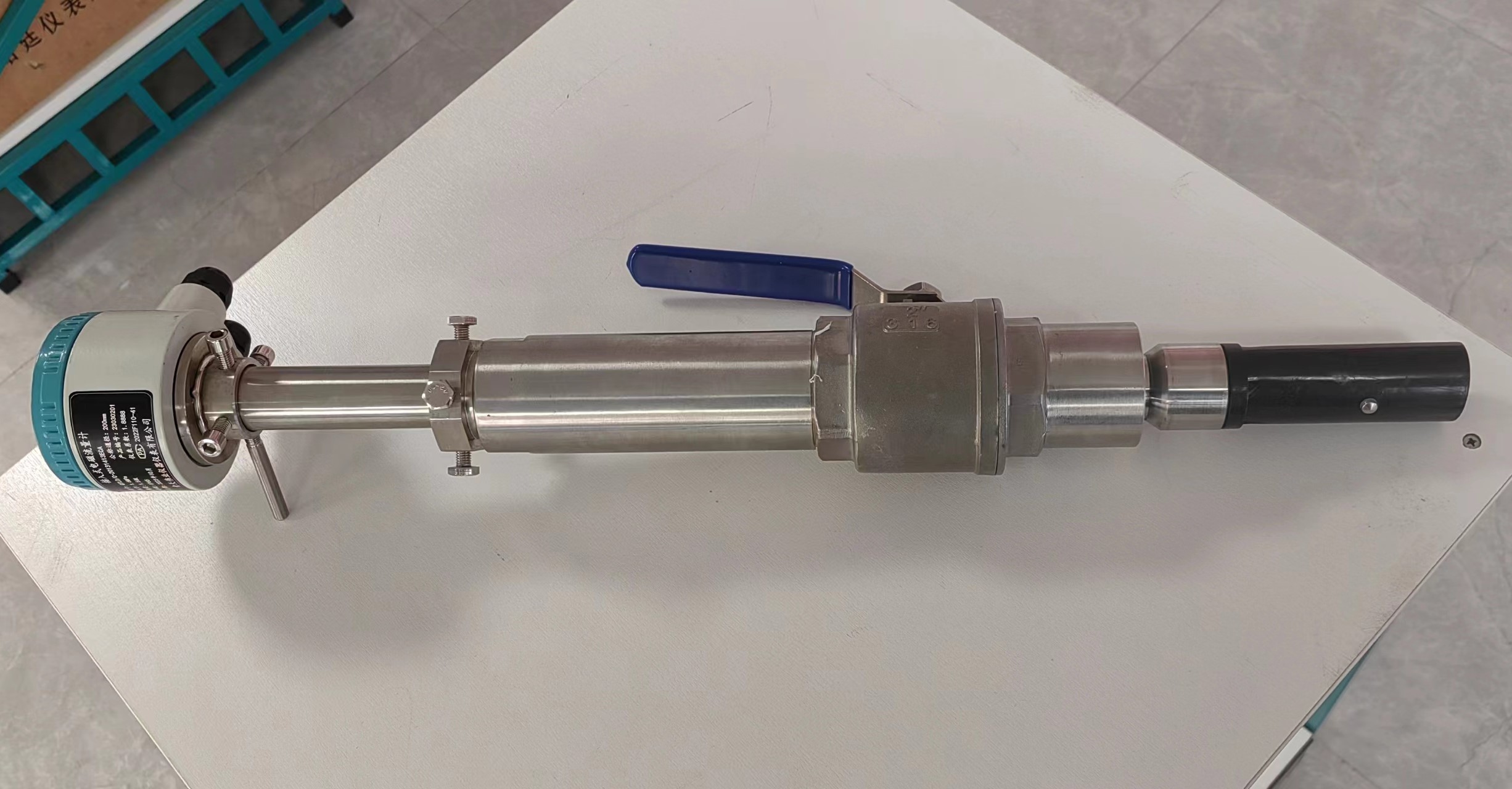

Electromagnetic flowmeters are classified into three types: integrated electromagnetic flowmeters, split electromagnetic flowmeters, insertable electromagnetic flowmeters, etc. Different types of flowmeters are used in different occasions. The correct selection of electromagnetic flowmeters is a powerful boost to work efficiency.

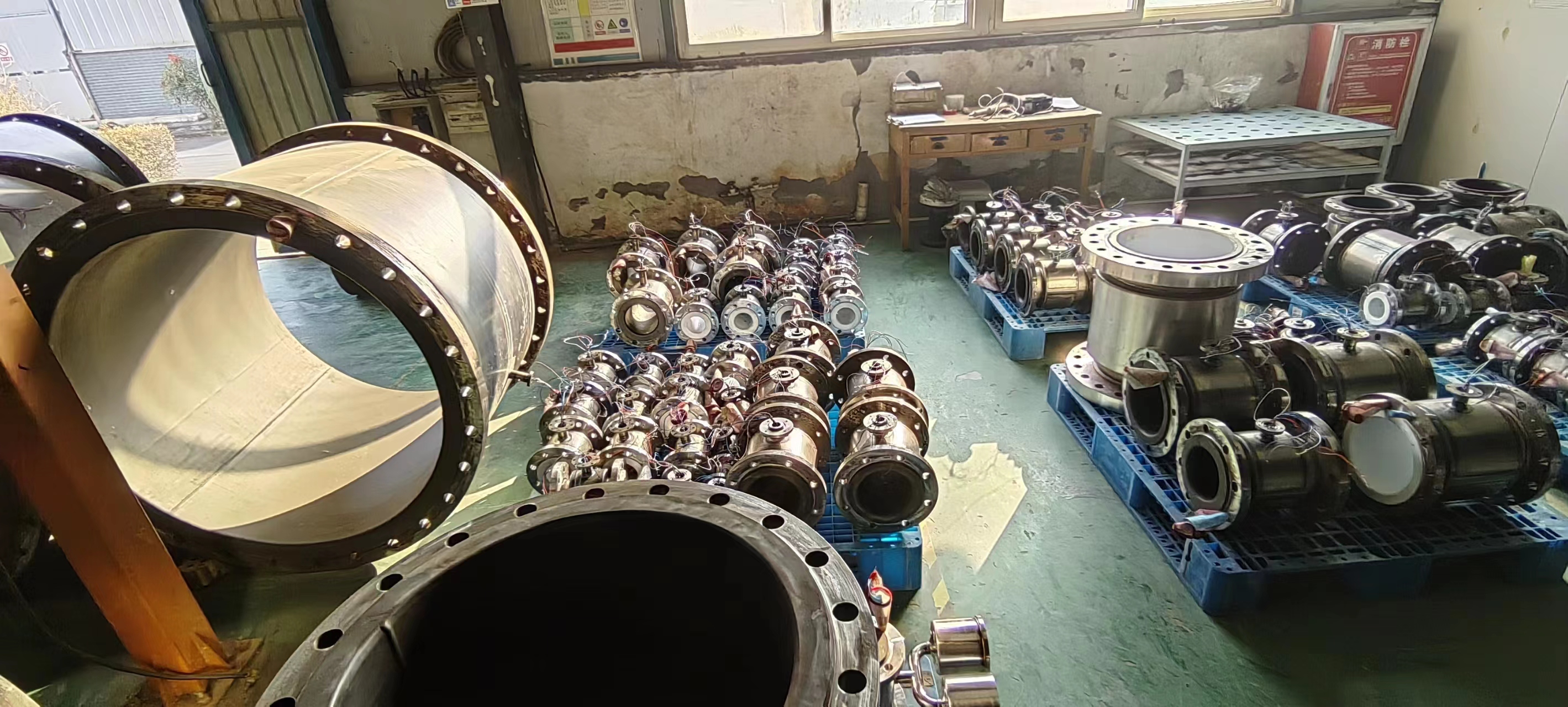

In industries such as metallurgy, papermaking, and sewage treatment, electromagnetic flowmeters are generally of split type and large-diameter flange connection type. In industries such as biomedicine and chemical engineering, small-diameter, integrated clamp connection methods are more commonly used. Different fields require different specifications of electromagnetic flowmeters.

In industries such as food hygiene and medicine, it is required that the sensors of electromagnetic flowmeters be easily disassembled, making cleaning convenient and facilitating regular steam sterilization. Therefore, in the health industry, electromagnetic flowmeters must meet the requirements of a hygienic type.

3. The instruments used in the channel are submersible type, mainly for industrial drainage and sewers. They need to rely on the power of the hoist to carry out relevant drainage work. At the same time, the sensor of the electromagnetic flowmeter should be installed at the lower part of the baffle of the open channel and should be immersed in water for a long time.

4. In some special places, such as explosion-proof environments, the instrument needs to have excellent explosion-proof and flame-retardant performance. In these situations, the energy of the excitation current is very large. Explosion-proof electromagnetic flowmeters can be classified into several types, including airtight type, diaphragm type and sand-filled type.

-.jpg)

-.jpg)