How to select circulating water flowmeter? Fully analyze and recommend the best options

The selection of circulating water flowmeter is a decision process involving many aspects, which needs to consider the characteristics of circulating water, measurement requirements, environmental conditions, economic costs and the performance characteristics of the flowmeter. Here is a comprehensive analysis and recommendations for the best options:

1. Characteristics analysis of circulating water

Flow rate and viscosity: Circulating water usually has a low flow rate and a low viscosity. Therefore, the selected flowmeter should be able to accurately measure at low speeds and low viscosity conditions.

Pollution situation: Circulating water is prone to pollution, so the flow meter should have pollution resistance characteristics to ensure long-term stable operation.

2. Clear measurement requirements

Accuracy requirements: Select the appropriate accuracy level according to the measurement requirements. High precision flowmeters are usually suitable for applications where the measurement results are very demanding.

Range: Determine the flow range of the circulating water and select a flowmeter with a range slightly larger than the required flow to avoid overflow at peak flow.

3. Consideration of environmental conditions

Temperature and pressure: Understand the temperature and pressure of the circulating water medium to ensure that the selected flowmeter can work stably under the appropriate conditions.

Protection level: Select the appropriate protection level according to the installation environment to protect the flow meter from harsh environments.

4. Flowmeter type selection

There are various types of circulating water flowmeters, and the common ones are as follows:

Vortex flowmeter

Features: Based on the principle of fluid mechanics, it has the characteristics of high precision, long life and fast response.

Application scenario: Applicable to the application scenario where the circulating water viscosity is low and the flow rate is wide.

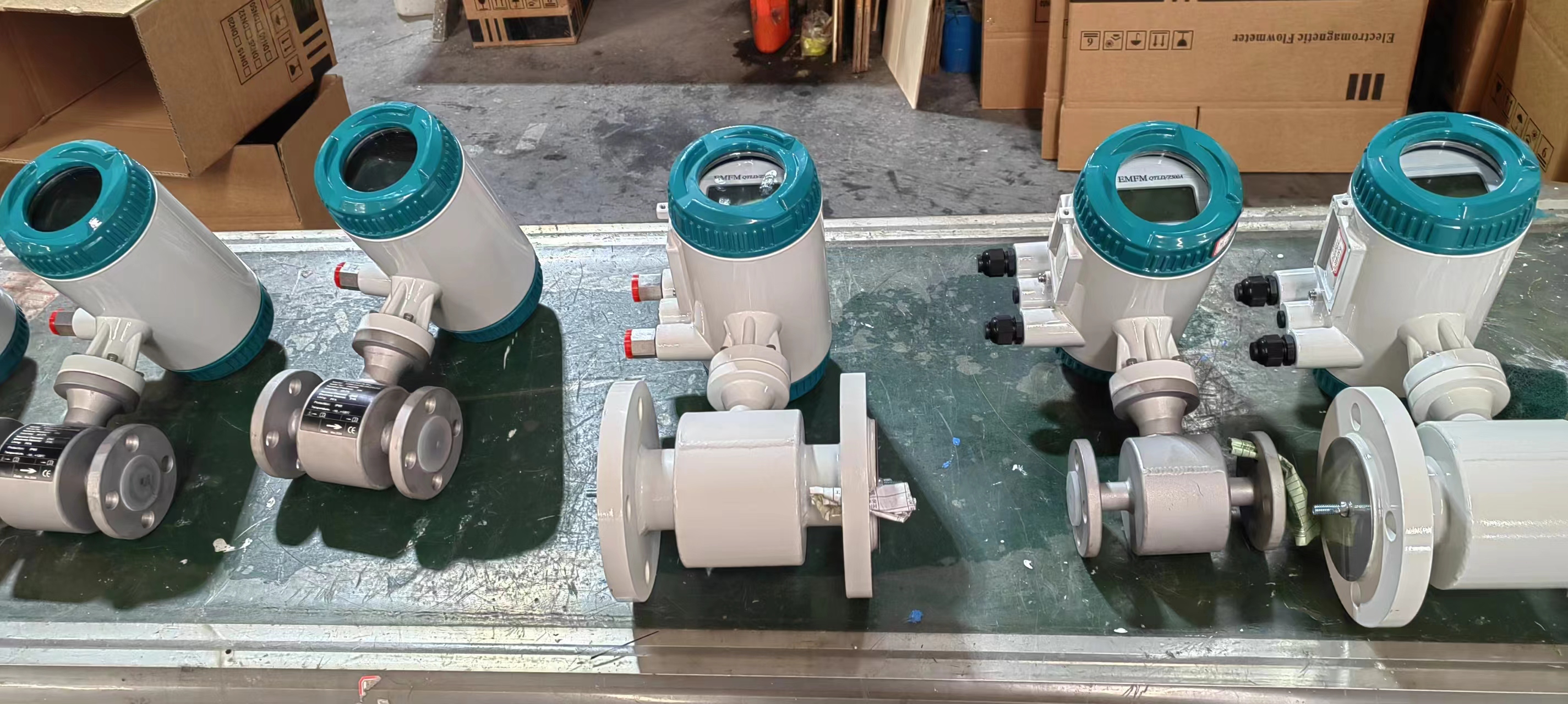

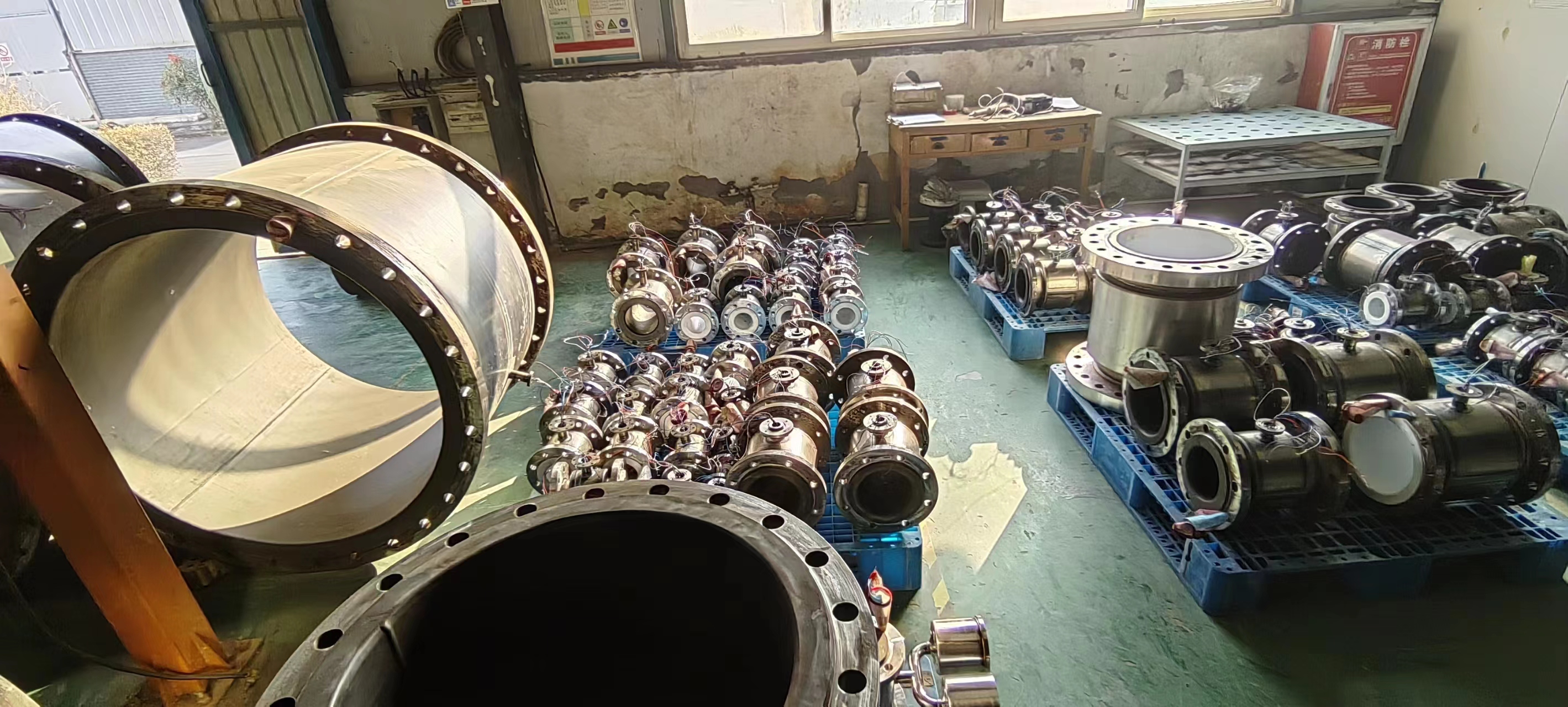

Electromagnetic flowmeter

Features: The flow rate is measured by measuring the influence of the fluid on the magnetic field, with high accuracy, corrosion resistance, and is not affected by temperature and viscosity changes.

Application scenario: It is suitable for the application scenario where the viscosity of circulating water is small and the medium contains corrosive substances.

Ultrasonic flowmeter

Features: Through the measurement of ultrasonic speed and reflection in the liquid to measure the flow, with high accuracy, no mechanical moving parts, suitable for a variety of liquid characteristics.

Application scenario: It is especially suitable for the application scenario where the circulating water flow rate is low and the medium is liquid.

Mass flowmeter

Features: By measuring the ratio of instantaneous mass and time of liquid flow meter to measure flow rate, not affected by temperature and pressure changes, wide measuring range and high precision.

Application scenario: Applicable to the application scenario where the viscosity of circulating water is low and the measurement range is relatively small.

5. Other considerations

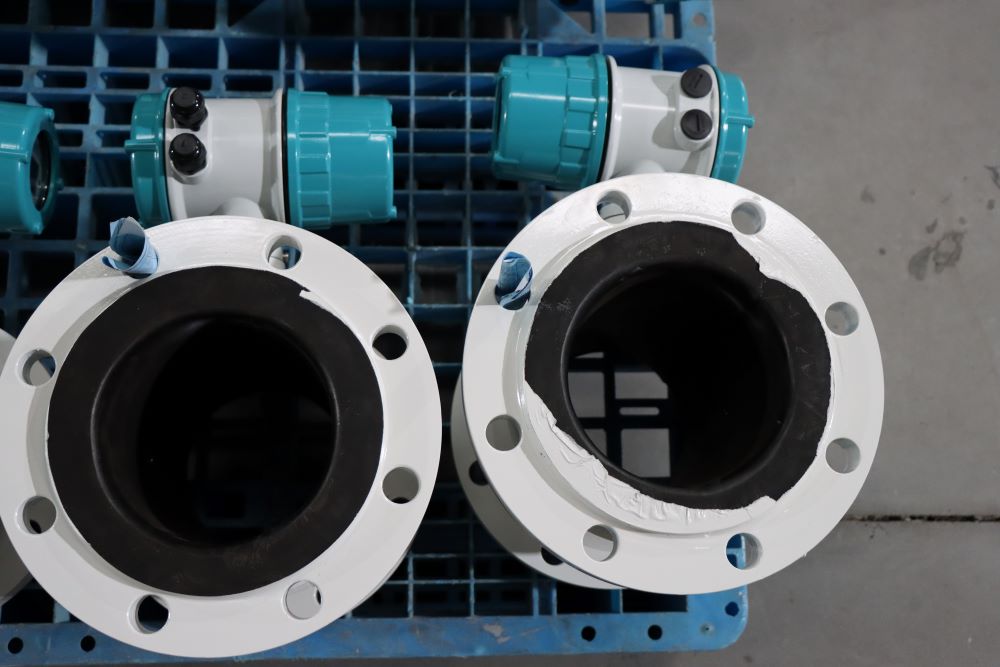

Installation mode: Select the appropriate installation mode according to the site conditions, such as side mount, top mount, insert type or flange type. Side-mounted and plug-in types are more commonly used, respectively, for small pipelines or small flow metering occasions and large diameter pipelines.

Electrode and lining material: According to the corrosion and wear of the measured medium, select the appropriate electrode and lining material to extend the service life of the flow meter.

Cost and maintenance: Consider the cost of the flow meter, late maintenance costs and replacement cycle and other factors, choose cost-effective products.

6. Recommend the best option

Taking the above factors into consideration, vortex flowmeter or ultrasonic flowmeter is recommended for the measurement of circulating water flow. These two flowmeters have high applicability in circulating water measurement and can meet most measurement requirements. The specific type needs to be determined according to the actual application scenario and measurement requirements. For example, if the circulating water contains corrosive substances and requires high precision, a magnetic flowmeter may be a better choice. If the measurement range is small and the accuracy is very high, the mass flowmeter may be more suitable.