Electromagnetic flow meter one type and part type correct selection

The correct selection of electromagnetic flowmeter is the prerequisite to ensure that the electromagnetic flowmeter can be used well. The choice of electromagnetic flowmeter needs to be determined according to the physical and chemical properties of the tested conductive liquid medium.

Important factors to consider: electromagnetic flowmeter diameter, flow range (larger flow, smaller flow), lining material, electrode material, output signal. So when do we choose one body type and one body type?

Monotype and subtype have their own advantages, and the basic principles of selection are:

A body type: In the field display, and the environment is better conditions, generally choose a body type, that is, the flow sensor and flow converter are assembled into one.

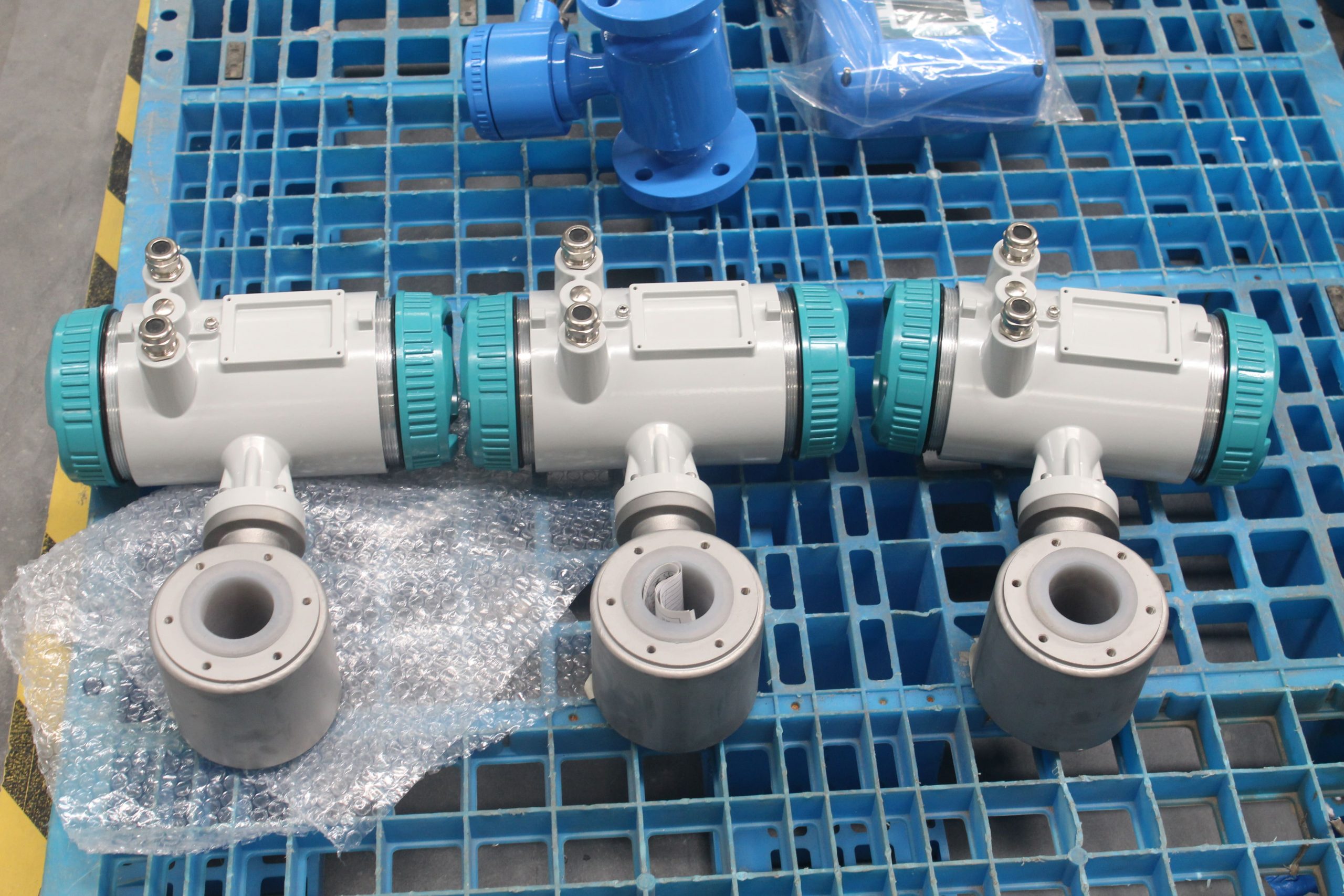

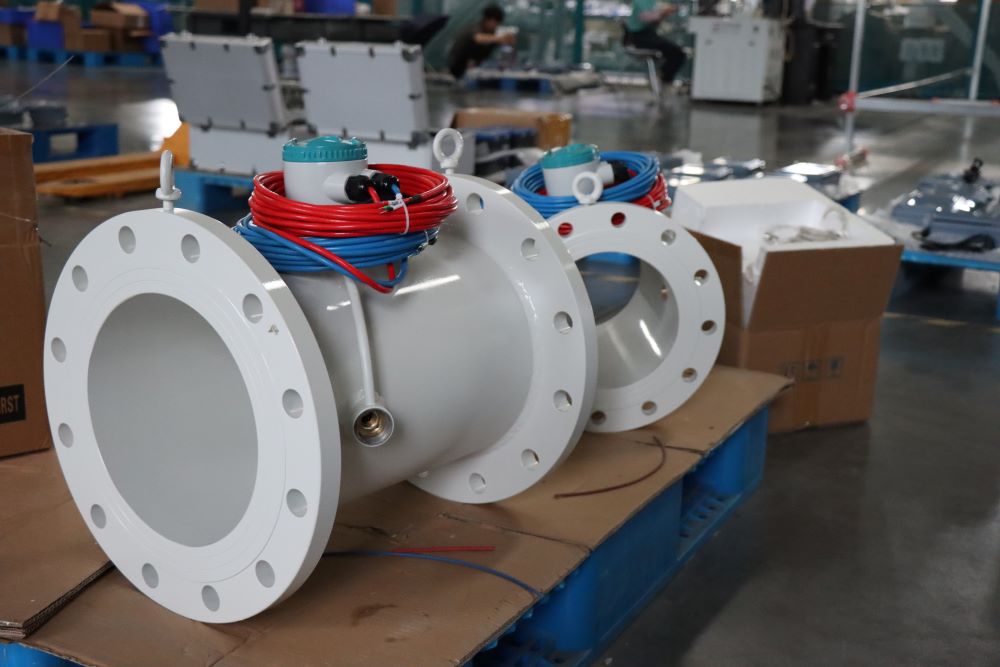

Sub-body type: that is, the flow sensor and flow converter are installed separately in different locations, and the sub-body type is selected when the meter appears in the following situations.

1. The ambient temperature or the radiation temperature of the flowmeter converter exceeds 60 degrees Celsius

2. The pipeline vibration is large

3. It will seriously corrode the aluminum shell of the converter

4. The site humidity is high or corrosive gases are present

5. The flowmeter is installed in the high altitude or underground debugging is not convenient occasions

-.jpg)