Electromagnetic flowmeter grounding problem

Electromagnetic flowmeter grounding problem

1. Why should the electromagnetic flowmeter be grounded?

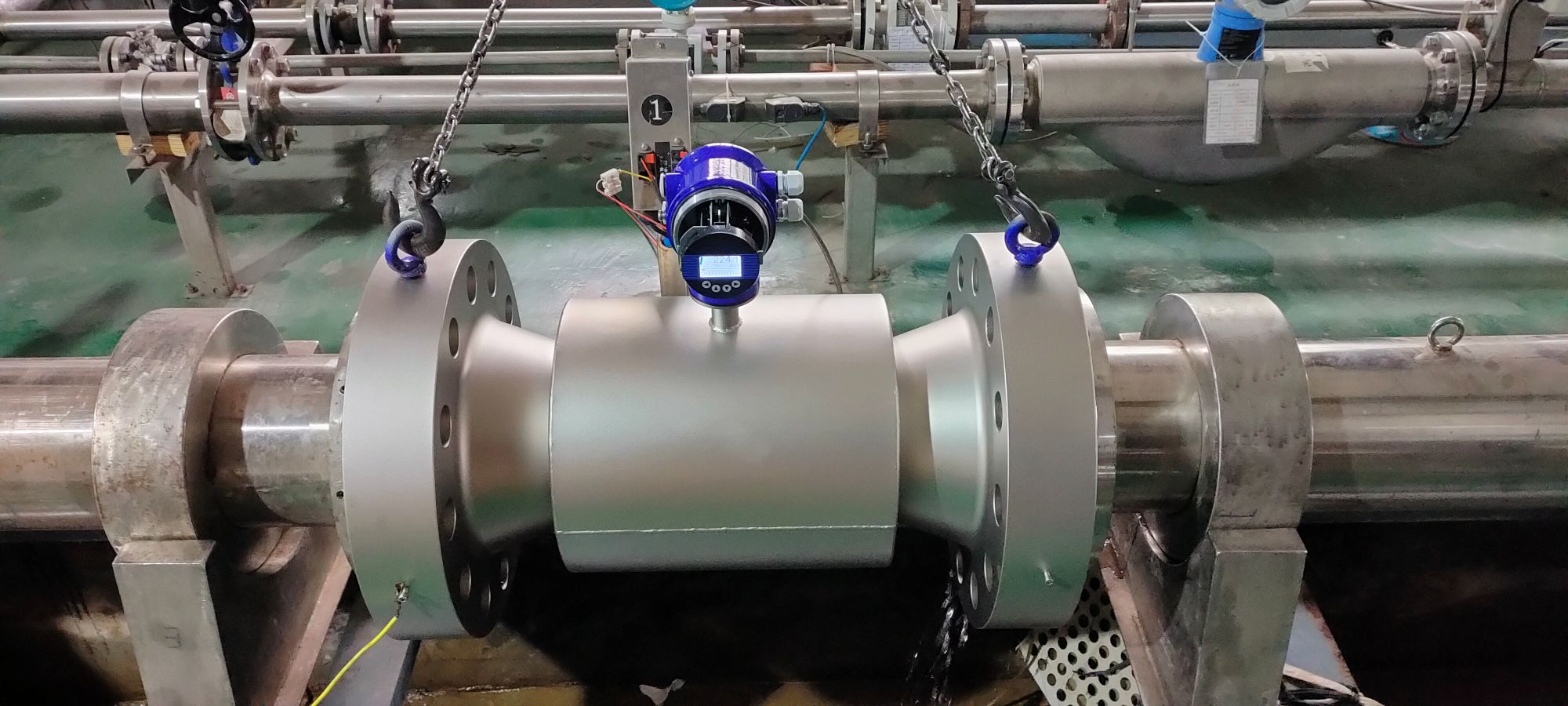

The ground point of the output signal of the electromagnetic flowmeter sensor should be electrically connected with the measured medium, which is a necessary condition for the operation of the electromagnetic flowmeter. If this condition is not met, the electromagnetic flowmeter cannot work normally, which is determined by the signal loop of the sensor. When the fluid cuts the magnetic field line to produce a flow signal, the fluid itself is zero potential, a positive potential is generated on one electrode, and a negative potential is generated on the other electrode, constantly changing. Therefore, the midpoint of the converter input (the signal cable shield) must be at zero potential with the fluid and be on, so as to form a symmetrical input loop. The midpoint of the input end of the converter is electrically connected with the measured current through the ground point of the output signal of the sensor.

2, electromagnetic flowmeter grounding precautions

(1) The ground point of the instrument should be an independent ground point, and it is not allowed to be connected with the ground wire of other electrical equipment. The ground resistance should be less than 10 Ω, and some types of meters specify that it should be less than 100Ω.

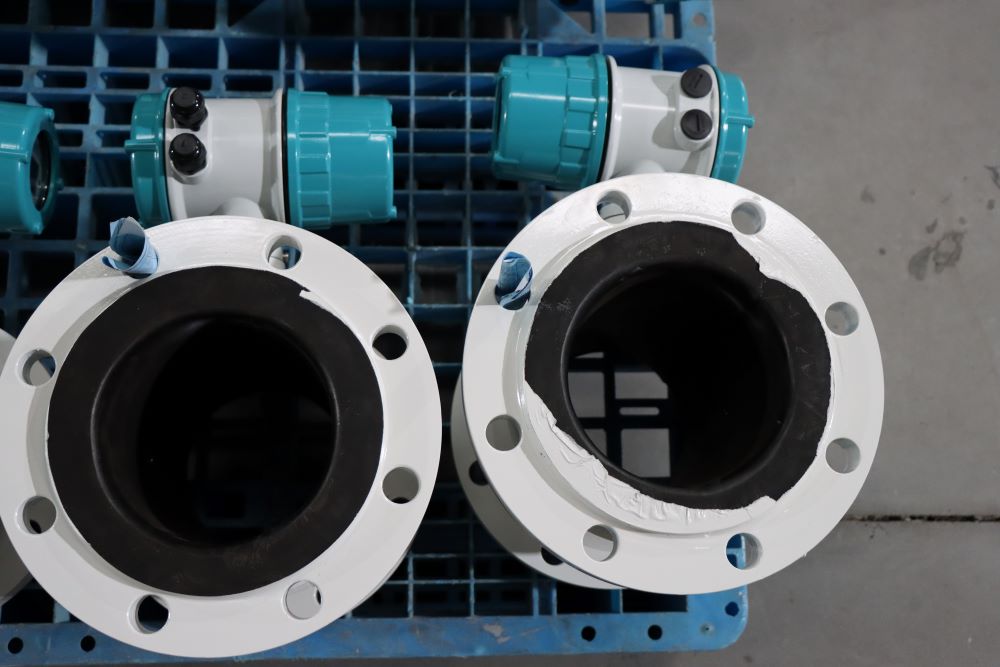

(2) When the sensor is installed on the insulated pipe, both ends must be installed with a ground ring, and then connected with a wire, and the fluid “conduction”, if the measured medium conductivity is low, the use of metal short tube instead of the ground ring, to ensure the grounding effect. The grounding ring acts as the ** bar. The metal process pipe is in direct contact with the medium, and the ground wire is directly connected with the metal pipe or flange, so there is no need for a ground ring.

-.jpg)