Find out what the main sources of faults in electromagnetic flowmeters are

The main sources of faults in electromagnetic flowmeters caused by pipeline systems and related equipment are:

1. Improper installation

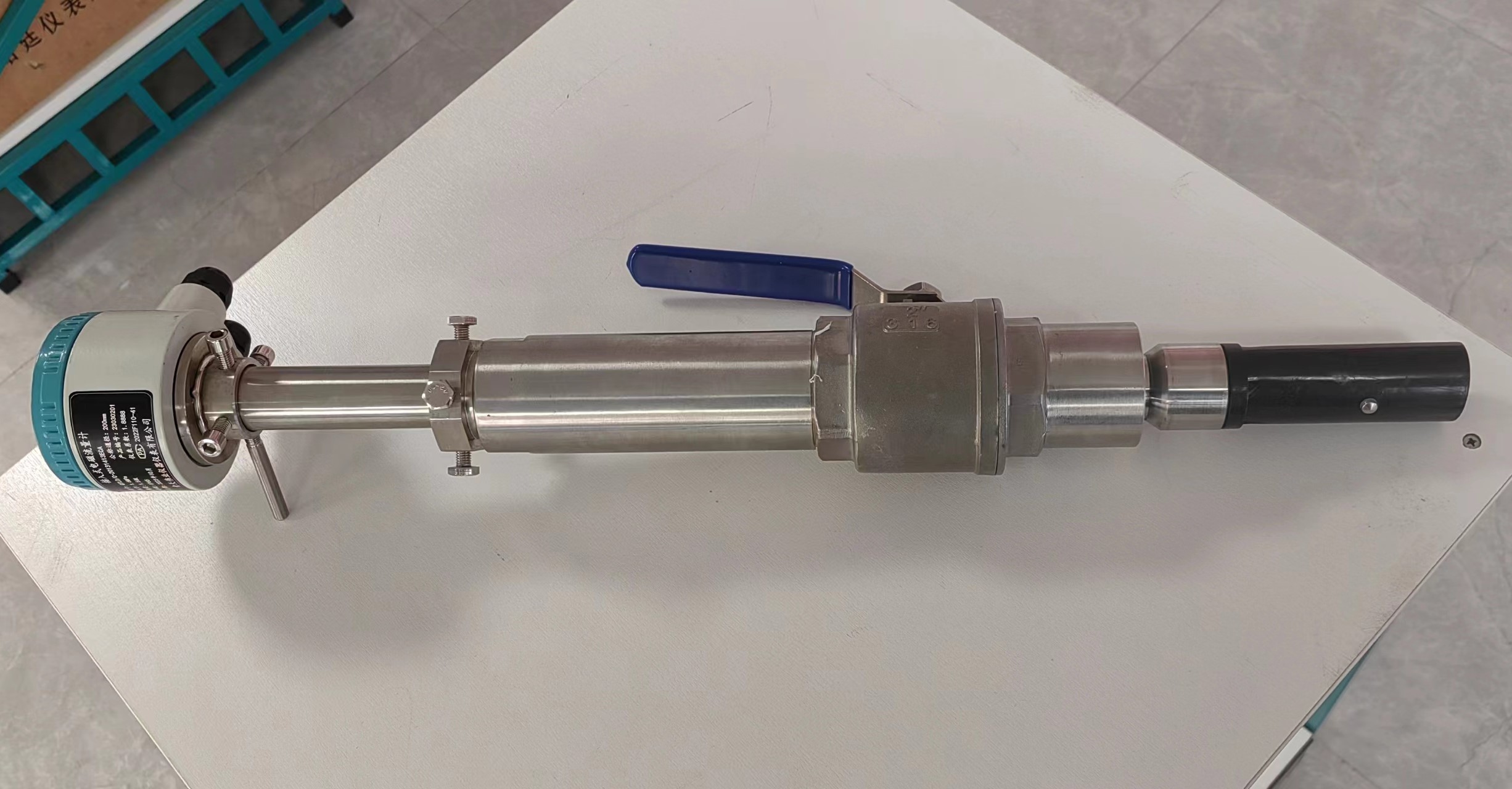

1) The inner diameter of the flow sensor and the connecting pipe is improperly matched, with a significant difference. (According to ISO9104:1991, without the manufacturer’s recommendation, the inner diameter of the connecting pipe shall not be less than the inner diameter of the flow sensor and shall not exceed 3% of the inner diameter.)

2) The gasket between the flow sensor and the pipe protrudes into the flow channel.

3) Severe distortion of the flow velocity distribution or rotational flow occurs in the flexible flow element in front of the adjacent flow sensor, and the straight pipe section is insufficient. These reasons mainly cause the flow measurement values to not match the actual values, and sometimes output fluctuations may also occur.

2. Not yet under management

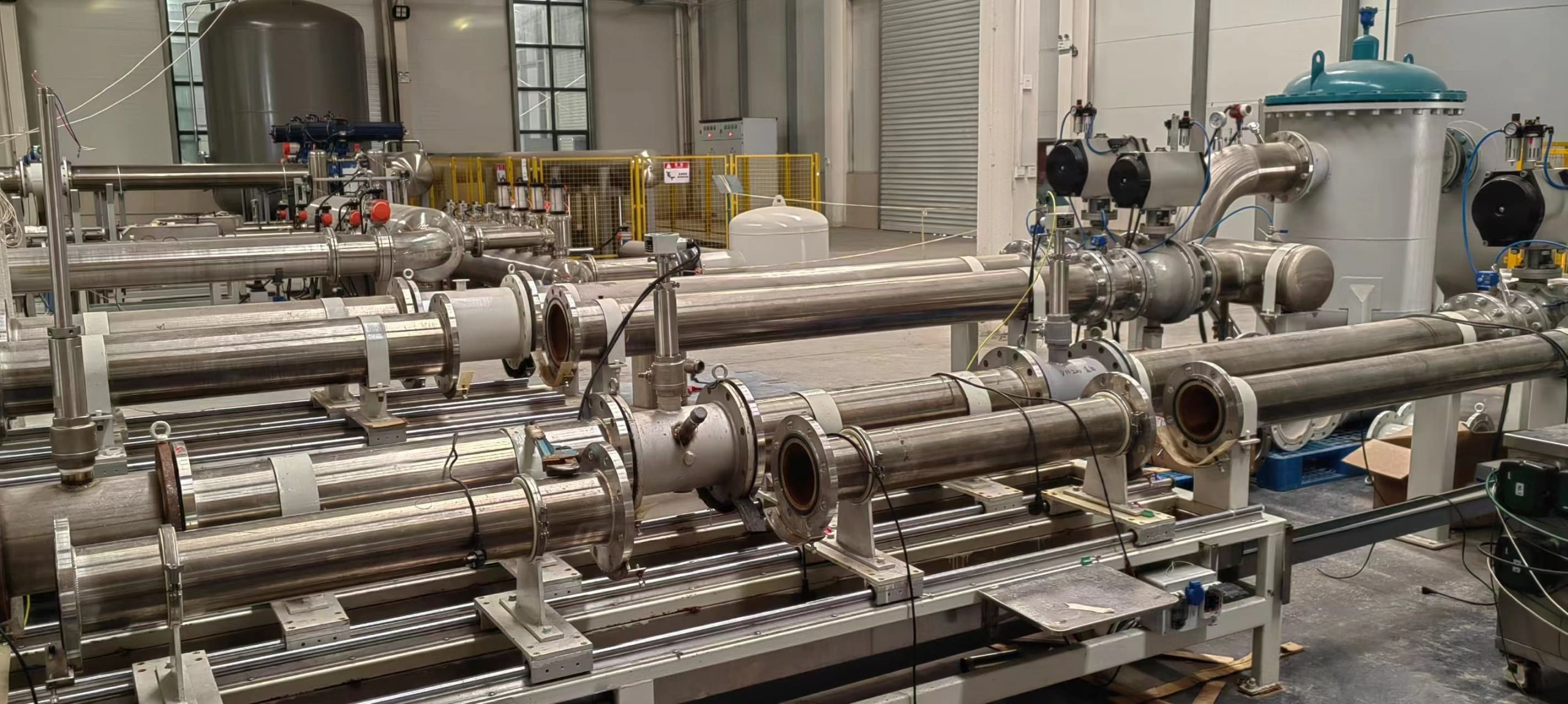

Due to insufficient back pressure or improper installation of the flow sensor, the liquid in the measuring tube failed to fill. The fault phenomenon varies depending on the degree of non-filling and the flow condition. If a small amount of gas flows in a horizontal pipeline in a stratified or wavy pattern, the fault phenomenon is manifested as an increase in error, that is, the measured flow value does not match the actual value. If the flow is bubble flow or plug flow, in addition to the discrepancy between the measured value and the actual value, the fault phenomenon will also cause output shaking due to the instantaneous gas phase covering the electrode surface. If the gas phase part of the flow area in the stratified flow of a horizontal pipe increases, that is, the degree to which the liquid does not fill the pipe increases, output shaking will also occur. If the liquid does not fill the tube and the liquid surface is below the electrode, an overfill output phenomenon will occur.

3. Gas retention in the piping system

One reason for the retention of gas in the piping system is that the air inside the pipes was not completely discharged before the system was put into use. The remaining gas accumulates at the high points of the piping system and is carried by the liquid when flowing, flowing out in the form of bubbles. Another reason is that small air bubbles carried in the liquid gradually accumulate and remain at the high points of the piping system. The fault is manifested as a discrepancy between the measured flow value and the actual value, as well as output shaking.

-.jpg)

-.jpg)