Electromagnetic flow meter in the use of precautions and installation requirements

Notes in the use of electromagnetic flow:

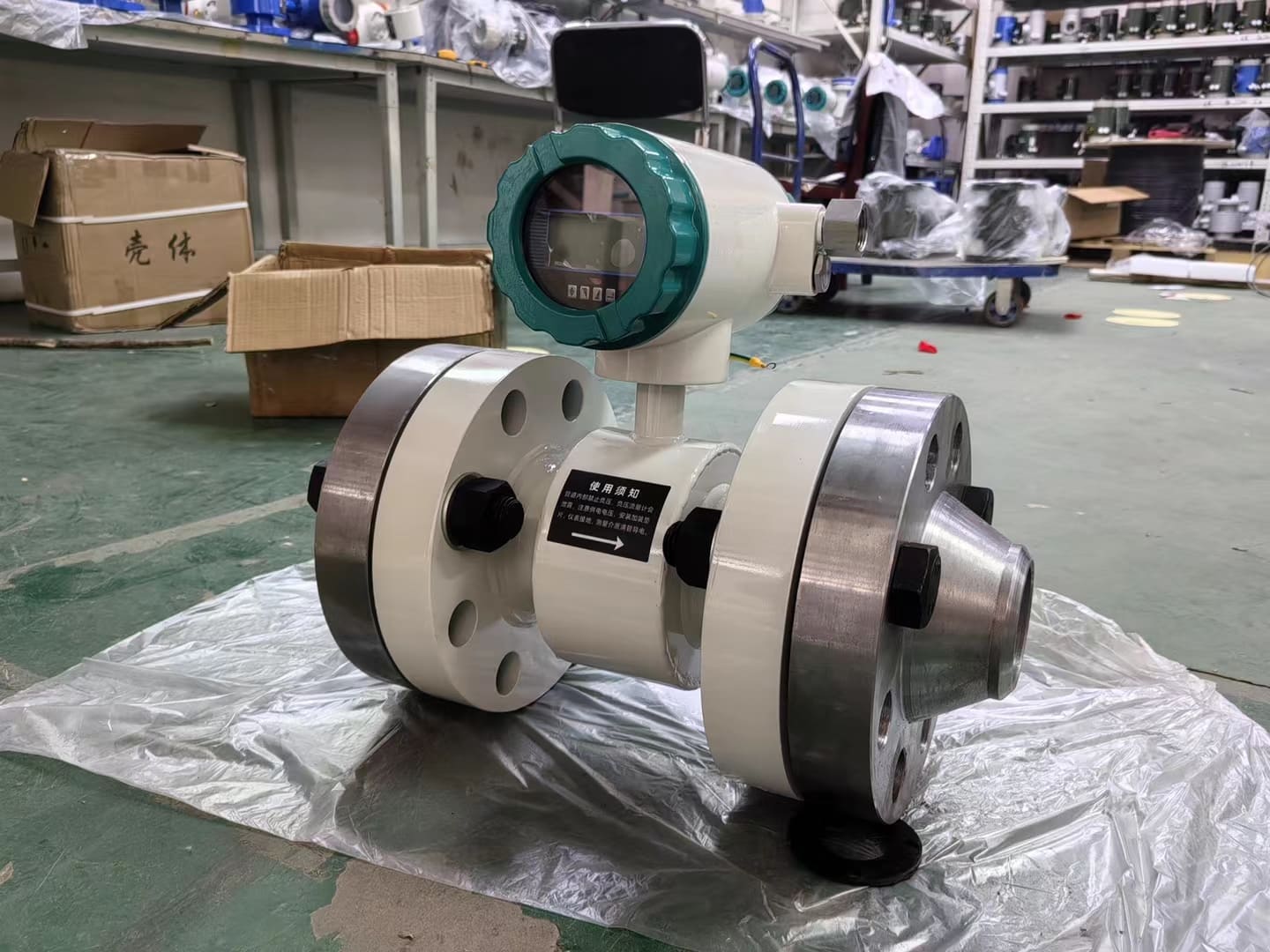

1, because the induction signal voltage of the electromagnetic flowmeter is very small, it is easy to be affected by noise. The reference potential must be the same as the liquid being measured. The correct grounding of electromagnetic flowmeter is directly related to the accuracy and stability of measurement.

Notes in the use of electromagnetic flow:

1, because the induction signal voltage of the electromagnetic flowmeter is very small, it is easy to be affected by noise. The reference potential must be the same as the liquid being measured. The correct grounding of electromagnetic flowmeter is directly related to the accuracy and stability of measurement.

(1) When the flow housing is grounded, the measured liquid is electrically connected to the earth and is at zero potential, so that a symmetrical potential signal of the same size but opposite polarity is induced on the two electrodes of the sensor; At the same time, the flowmeter housing is grounded, which can play a shielding effect to suppress the electromagnetic interference of the outside world and the excitation system.

(2) When there is a strong stray current in the pipeline, the stray current should be blocked from flowing through the flowmeter. Install an insulated short pipe between the pipe and the flow meter, and then connect the two ends of the pipe with a copper wire with an area of not less than 16mm2. In this way, the current in the pipe is diverted from the copper wire and no longer passes through the flow meter, thus reducing interference.

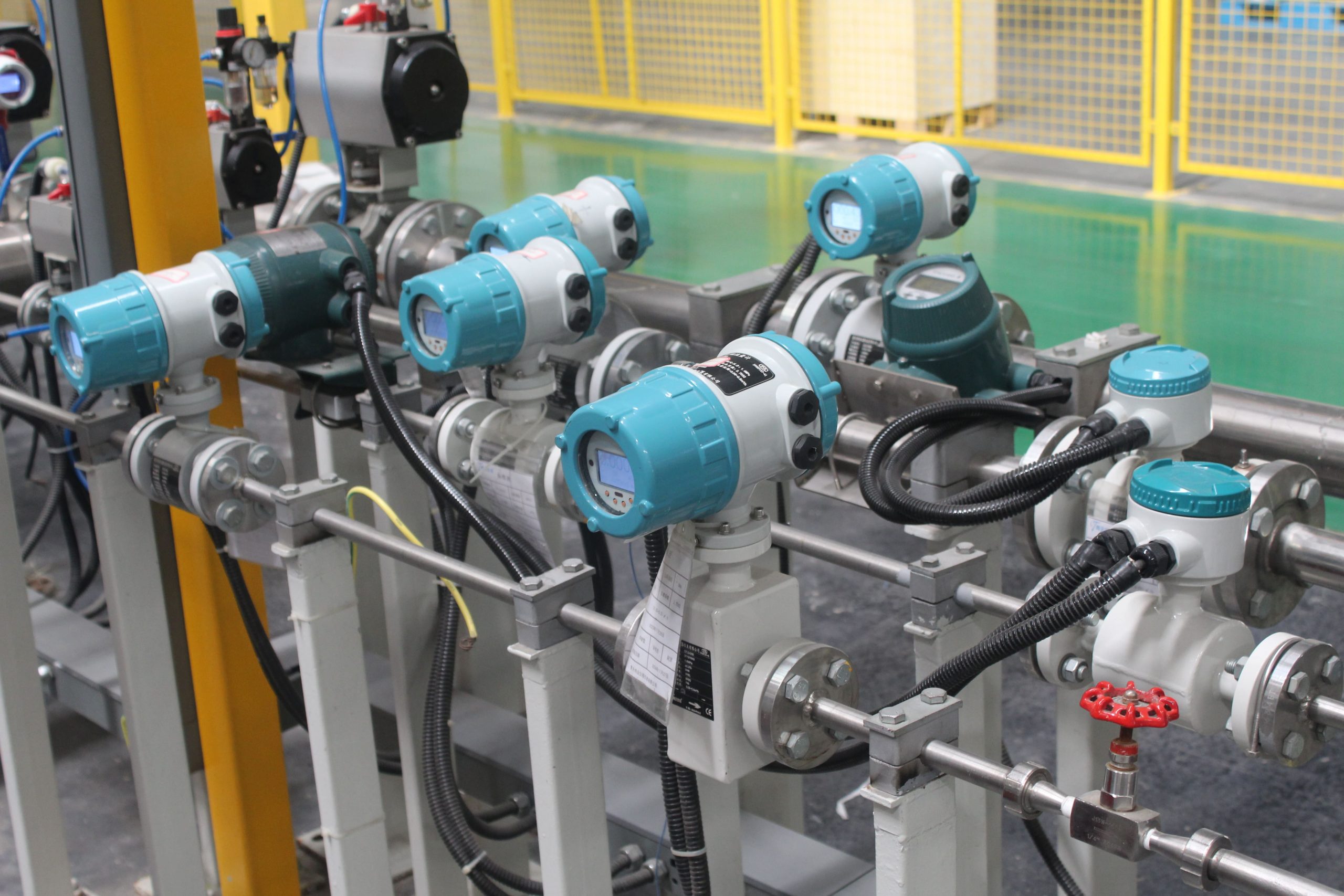

2, electromagnetic flowmeter installation position selection

(1) When there are elbows, valves and pumps on the installation position of the electromagnetic flowmeter and downstream, the fluid forms a transverse secondary flow in the pipeline, the flow rate distribution is deviated, and the measurement accuracy is decreased when the length of the straight pipe section is insufficient. In general, the length of the upstream straight pipe section is not less than 10D, and the length of the downstream straight pipe section is not less than 5D. When there are pumps and other equipment upstream, the length of the straight pipe section is required to be not less than 30D. Do not install the meter on the inlet side of the pump, which will cause a vacuum in the pipeline and make the measurement error. Where D is the inner diameter of the pipe.

(2) In the measurement to ensure that the pipeline filled with liquid, otherwise it will affect the measurement accuracy. In inclined or vertical installation, the measured liquid should flow from bottom to bottom. The measured liquid must not contain excessive bubbles.

(3) The strong vibration of the pipeline should be avoided as far as possible, if it can not be avoided, the sensor and the transmitter should be installed separately, and the pipeline should be fixed within 2 to 5D on the upper and downstream sides of the flow meter. Avoid damage to the transmitter due to strong vibration.

(4) There can be no large motor and other equipment near the flow meter, otherwise there will be induction interference, affecting the measurement accuracy of the instrument.

(5) The injection of chemicals is prohibited on the upstream side of the flow meter, so that the distribution of electrical conductivity is very easy to be uneven, resulting in serious interference with the measurement of the flow meter.

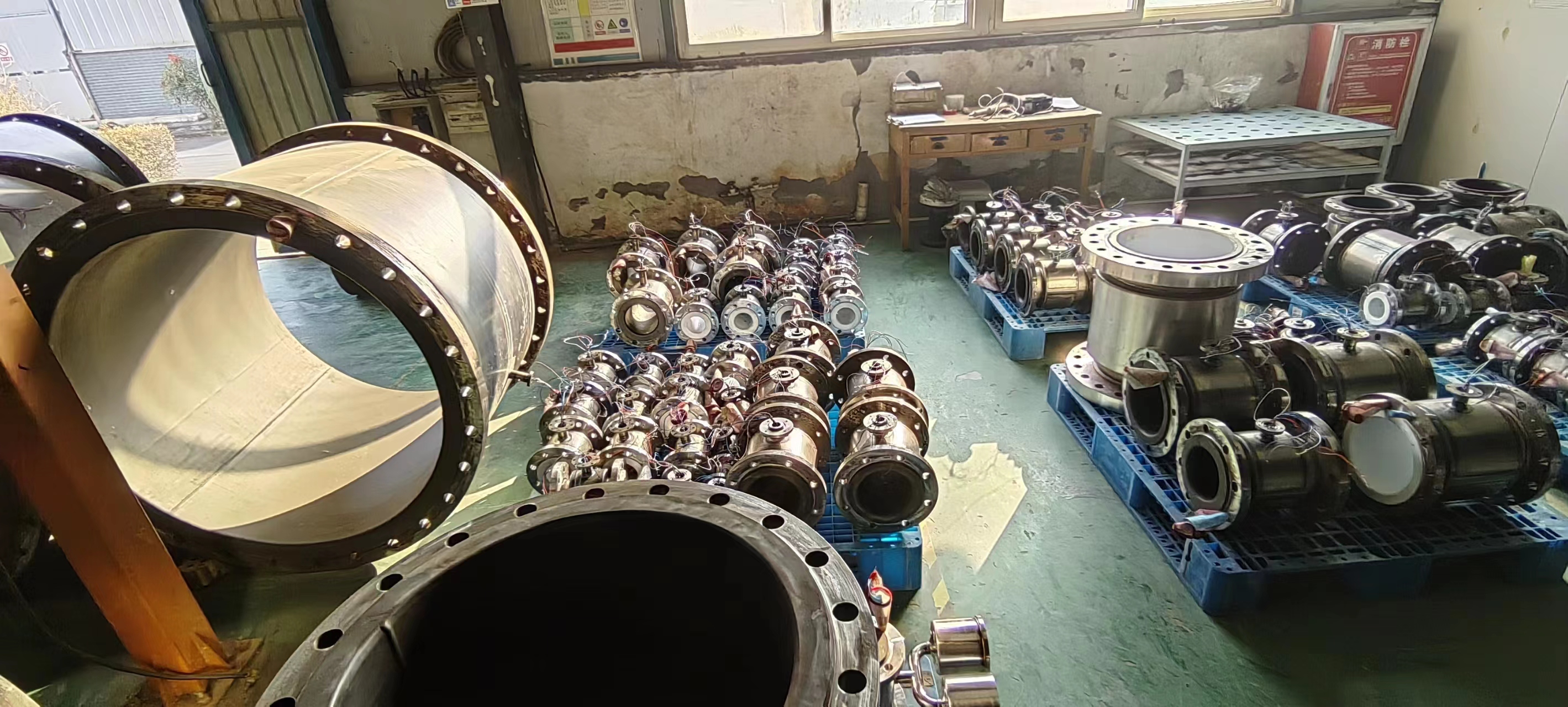

(6) In the installation of electromagnetic flow time, the axis of the electrode should be approximately horizontal when the horizontal installation, if the axis of the electrode is perpendicular to the ground, it is easy to gather bubbles near the upper electrode, blocking liquid contact with it, and the electrode below is easy to be covered by dirt

-.jpg)

-.jpg)