How to deal with the failure of ultrasonic level meter?

How to deal with the failure of ultrasonic level meter in daily work?

1, in order to prevent the ultrasonic level meter signal line by the power line strong voltage, large current, strong electromagnetic interference. The signal line goes through the wire tube separately, away from the power line and the lighting line, and wired separately;

2, do a good signal shielding layer to prevent signal interference;

3, in order to prevent poor contact of the signal line, try not to leave a connector in the middle of the signal line, the terminal crimp can not have any loose, otherwise the contact resistance will be larger. If there is a joint, it is necessary to weld the signal line joint with a soldering iron to reduce the hidden trouble;

4. In order to avoid moisture on the ultrasonic level gauge signal line, the signal line should be placed on the support when walking the cable. The signal line, especially the junction, is soaked in water and damp, which will cause the disturbance of the instrument signal.

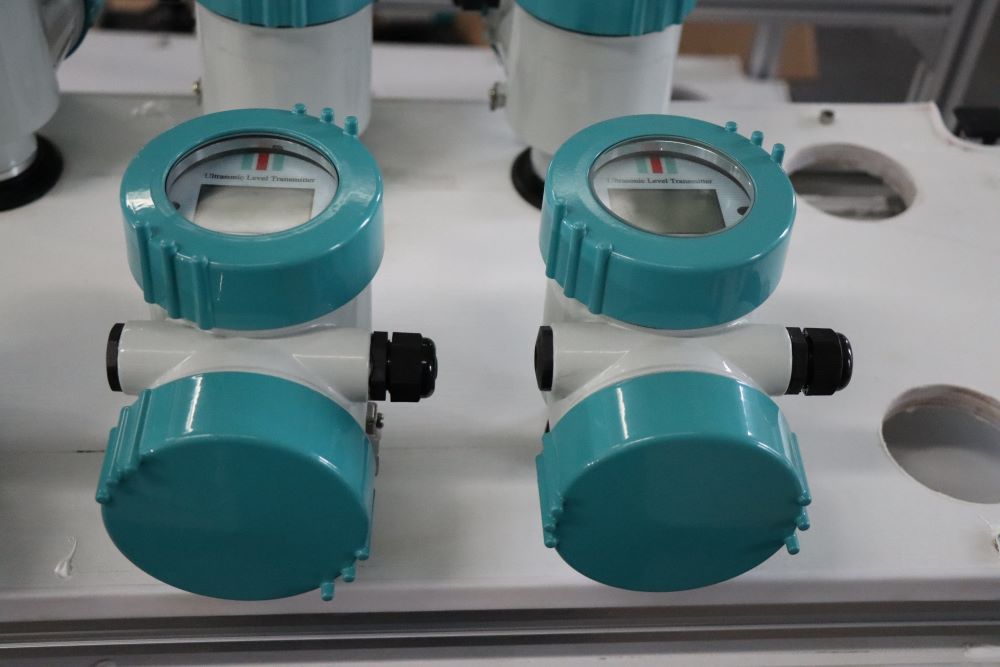

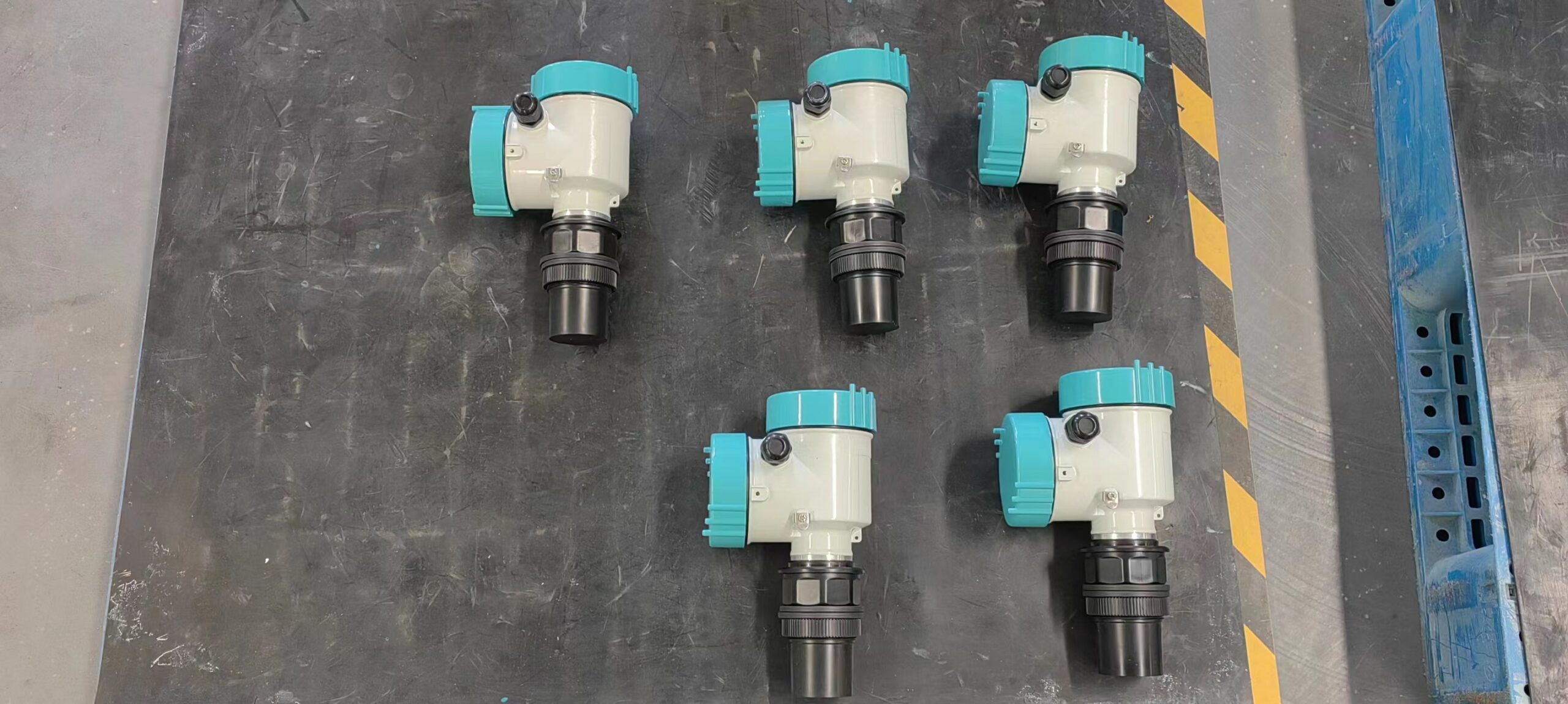

5, adjust the transducer of the ultrasonic level meter, the surface is perpendicular to the measured liquid level, and the levelness is controlled at 2°;

6. Adjust the distance between the ultrasonic probe and the liquid surface. When too far, the signal received by the probe is too weak to be distinguished from the noise signal, and when it is too close, it can not be distinguished from the blind area of the probe.