Analysis of Key Points for Selecting Vortex Flowmeters: Precise measurement, efficient operation

In industrial process control, energy measurement and gas/liquid flow monitoring, vortex flowmeters have become an important choice for flow measurement due to their advantages such as simple structure, wide range and high stability. However, in the face of different working conditions and application requirements, how to make the correct selection is of vital importance. This article will start from the key parameters to provide you with a detailed analysis of the selection points of vortex flowmeters, helping you achieve the best configuration.

In industrial process control, energy measurement and gas/liquid flow monitoring, vortex flowmeters have become an important choice for flow measurement due to their advantages such as simple structure, wide range and high stability. However, in the face of different working conditions and application requirements, how to make the correct selection is of vital importance. This article will start from the key parameters to provide you with a detailed analysis of the selection points of vortex flowmeters, helping you achieve the best configuration.

Measure the characteristics of the medium and fluid

Vortex flowmeters are suitable for gases, steam and liquids, but different media have an impact on measurement accuracy:

Gas/steam: Temperature and pressure compensation need to be considered to ensure accurate measurement.

Liquid: It is suitable for low-viscosity fluids (such as water, solvents), and high-viscosity media (such as heavy oil) may affect the vortex shedding frequency.

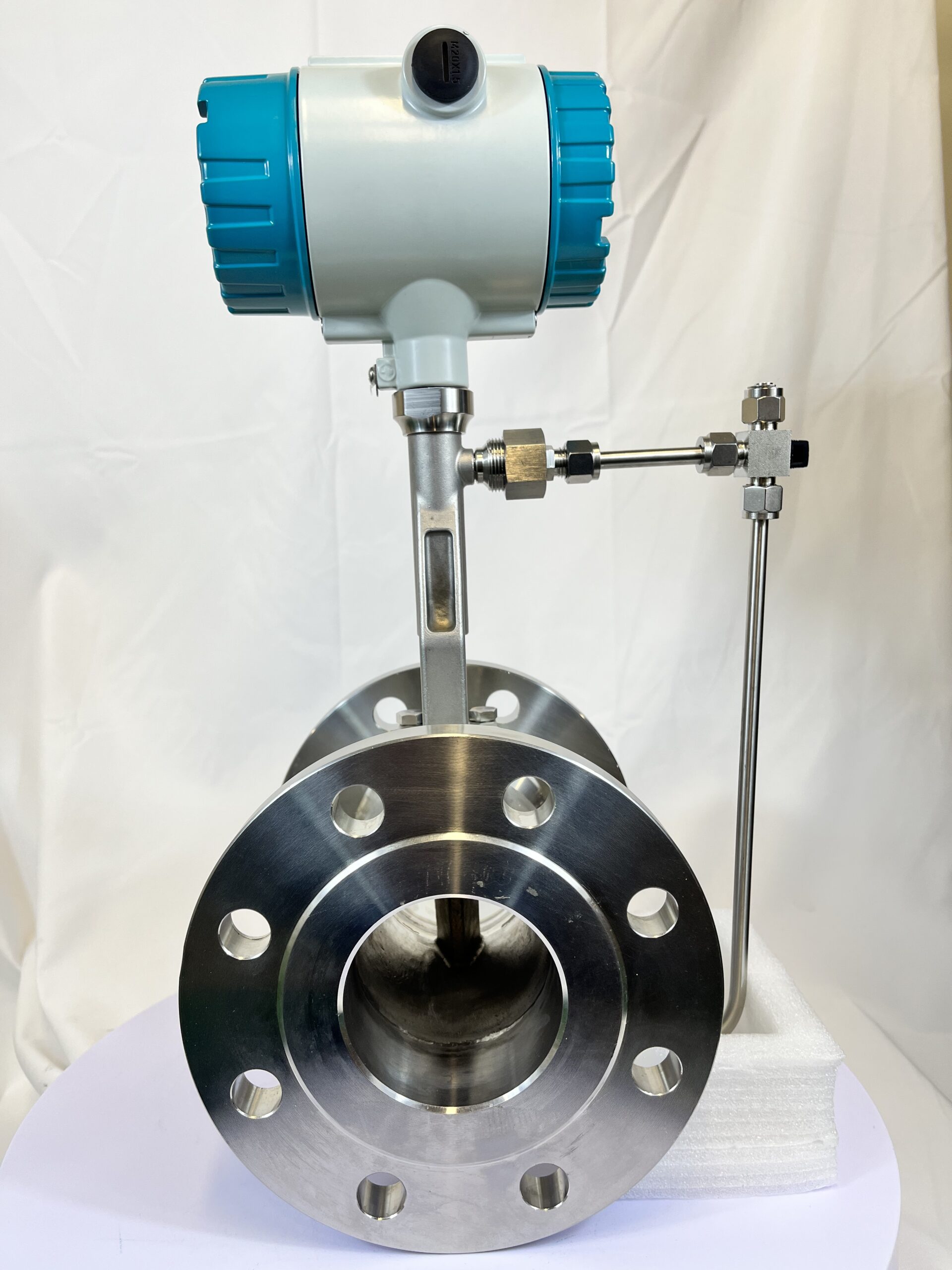

Corrosive media: Corrosion-resistant materials (such as 316L stainless steel, Hastelloy) should be selected.

2. The flow range matches the pipe diameter

Range ratio (range degree) : Usually 10:1 to 20:1. It is necessary to ensure that the minimum and maximum flow rates are within the instrument’s range.

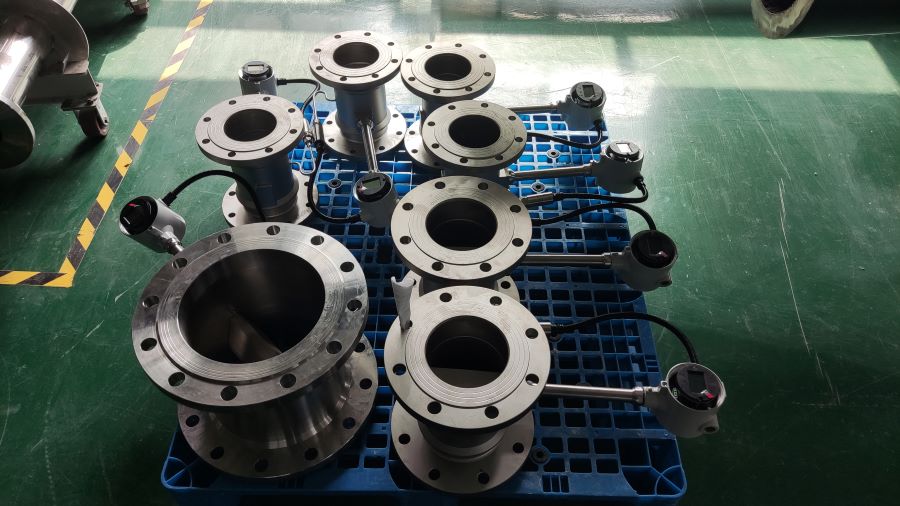

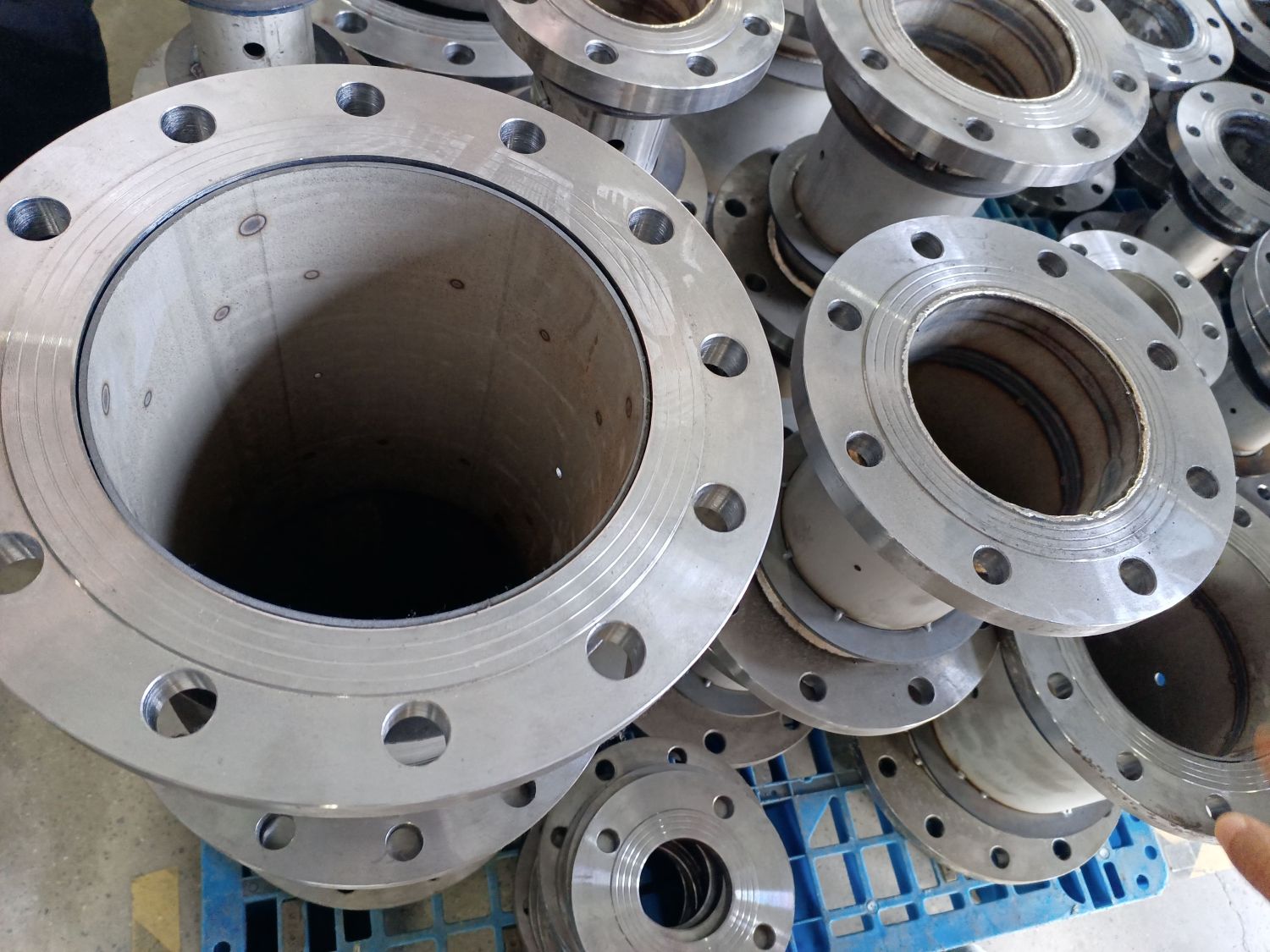

Pipe diameter selection: Small pipe diameters (DN15-DN50) are suitable for laboratories or small equipment, while large pipe diameters (DN80-DN300+) are suitable for industrial pipelines.

3. Temperature and pressure adaptability

High-temperature working conditions (such as steam) : High-temperature resistant sensors (up to 400℃) need to be selected.

High-pressure environment: Ensure that the pressure-bearing capacity of the flowmeter (such as PN16/PN25/PN40) meets the system requirements.

4. Precision grade and output signal

Accuracy: ±0.5% to ±1.0% for liquids, ±1.0% to ±1.5% for gases/steam. Higher accuracy is required for trade settlement.

Output mode: 4-20mA, pulse output, RS485 communication (supporting Modbus protocol), facilitating system integration.

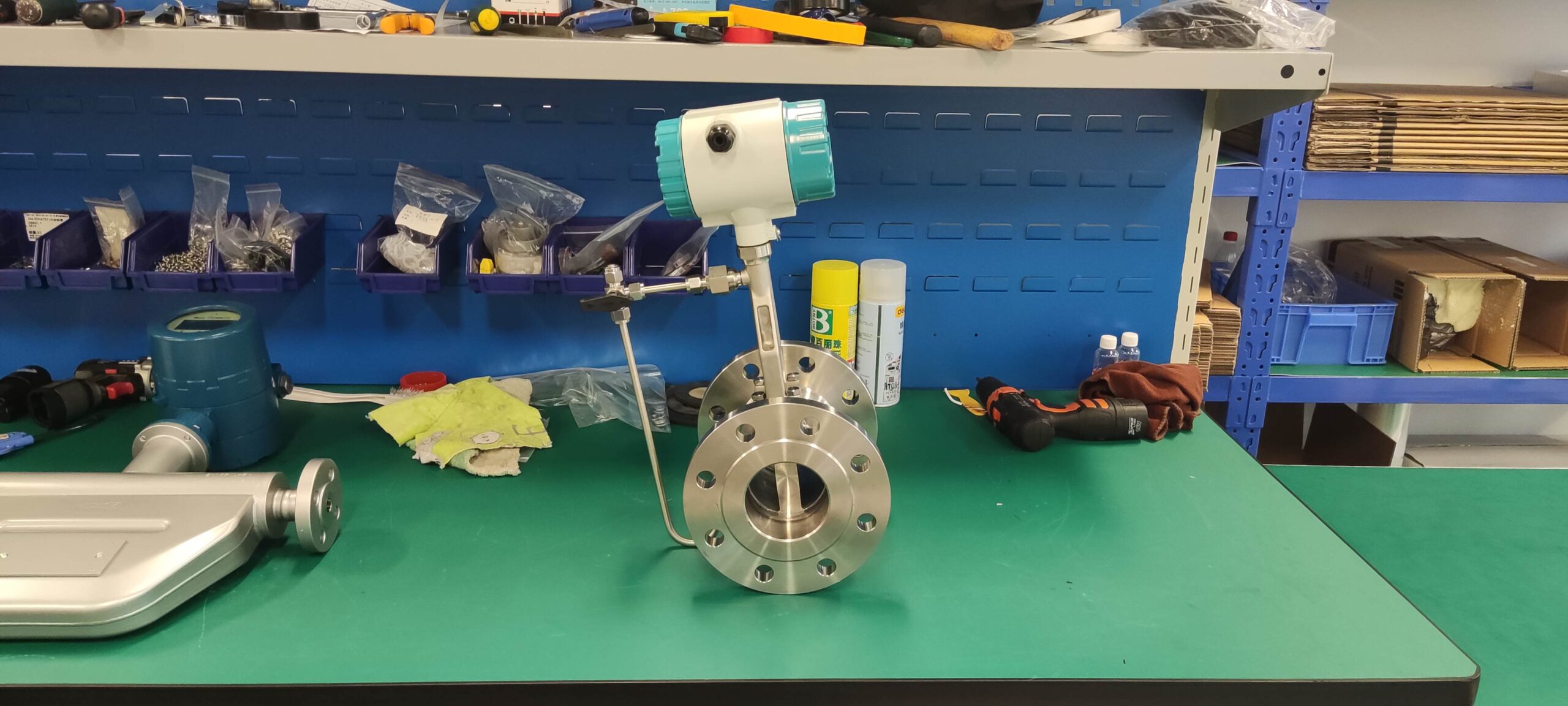

5. Installation method and vibration influence

Installation direction: For liquid measurement, it is recommended to install horizontally or vertically upwards; for gas/steam, it is recommended to install vertically.

Vibration interference: Avoid installation on strongly vibrating pipelines. If necessary, add vibration damping devices.