What common problems may intelligent electromagnetic flowmeters encounter?

What common problems may intelligent electromagnetic flowmeters encounter?

1. No flow output from the electromagnetic flowmeter: Check if there is a fault in the power supply section and test if the power supply voltage is normal. Test the continuity of the fuse; Check whether the arrow of the sensor is consistent with the flow direction of the fluid. If not, change the installation direction of the sensor. Check if the sensor is filled with fluid. If it is not, replace the pipe or install it vertically.

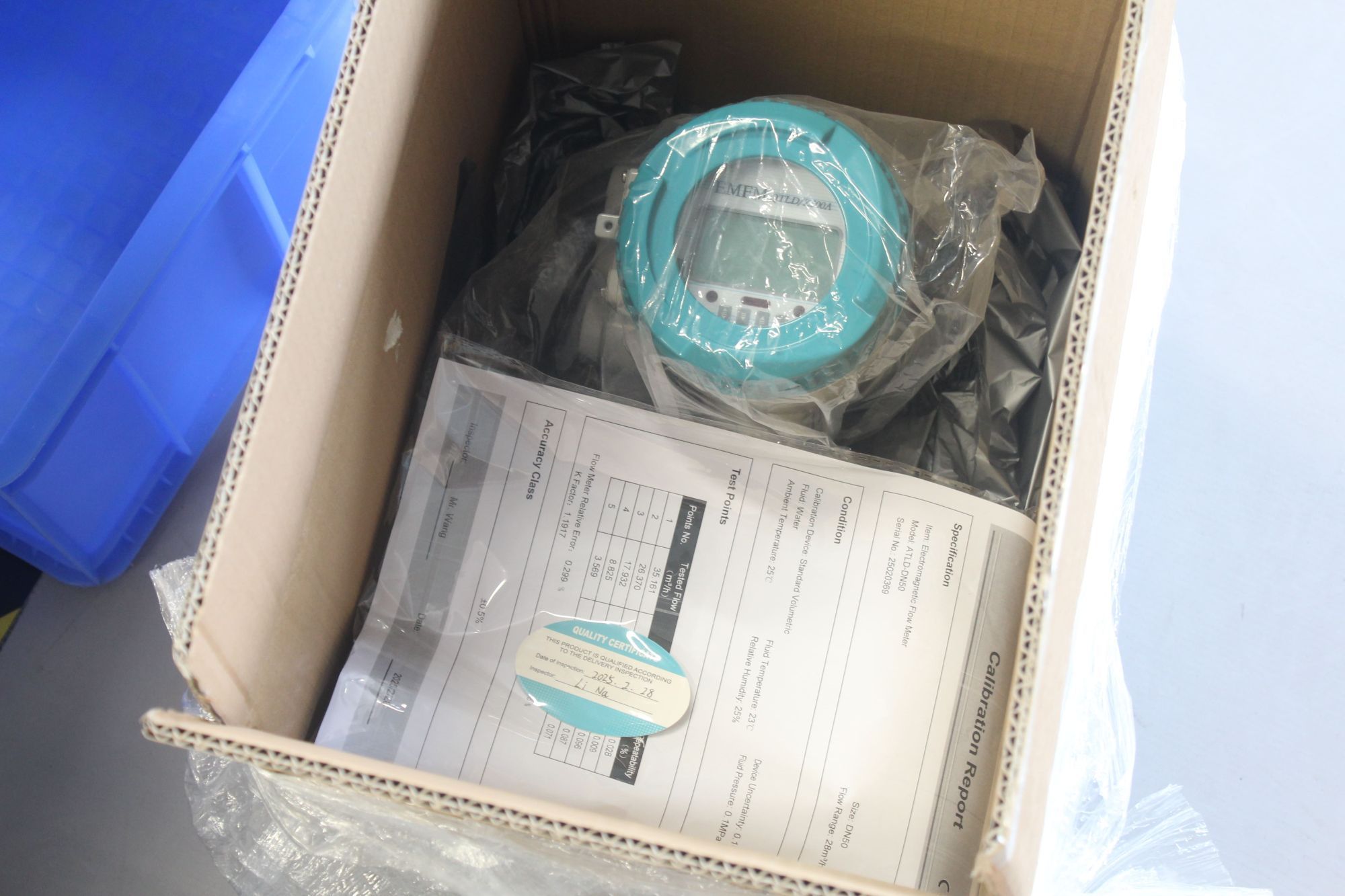

2. The signal of the electromagnetic flowmeter becomes smaller and smaller or suddenly drops: Test whether the insulation between the two electrodes is damaged or short-circuited. The resistance value between the two electrodes should be normally between (70 to 100)Ω. The inner wall of the measuring tube may accumulate dirt. The electrode should be cleaned and wiped. Do not scratch the inner lining. Check whether the lining of the measuring tube is damaged. If it is damaged, it should be replaced.

3. Unstable zero point of the electromagnetic flowmeter: Check whether the medium fills the measuring tube and whether there are bubbles in the medium. If there are bubbles, a degasser can be installed upstream. If it is installed horizontally, it can be changed to vertical installation. Check whether the grounding of the instrument is in good condition. If not, three-level grounding (grounding resistance ≤100Ω) should be carried out. The conductivity of the medium should be no less than 5μs/cm. Check whether the medium has accumulated in the measuring tube. When removing it, be careful not to scratch the inner lining.

4. If the flow indication value of the electromagnetic flowmeter does not match the actual value: Check whether the fluid in the sensor fills the pipe and if there are any bubbles. If there are bubbles, a degasser can be installed upstream. Check whether each grounding condition is good. Check if there is a valve upstream of the flowmeter. If so, move it downstream or fully open it. Check whether the range setting of the converter is correct. If not, reset the correct range.

5. If the reading of the electromagnetic flowmeter fluctuates within a certain range: Check whether the environmental conditions have changed. If new interference sources or other magnetic sources or vibrations that affect the normal operation of the instrument appear, the interference should be removed in time or the flowmeter should be moved. Inspect the test signal cable and apply insulating tape to the ends to ensure that the wires, inner shielding layer, outer shielding layer and housing do not come into contact with each other. The fluid used to measure flow with an electromagnetic flowmeter must be conductive. Therefore, non-conductive substances such as gases, steam, oils, and copper cannot be measured by an electromagnetic flowmeter.