To ensure the long-term operation of an intelligent electromagnetic flowmeter, the following points must be adhered to

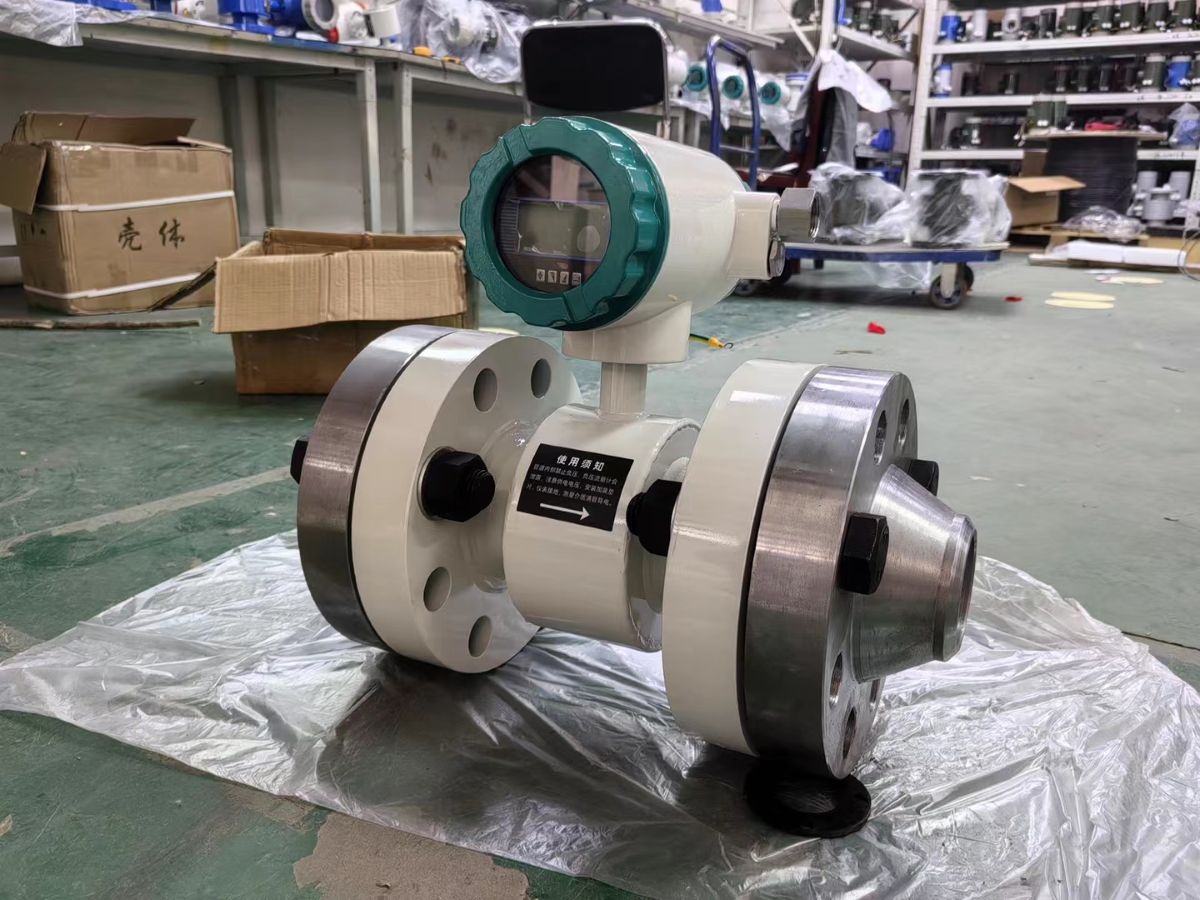

The measurement principle of the electromagnetic flowmeter is Faraday’s law of electromagnetic induction. It is an instrument that measures the flow of conductive fluids based on the induced electromotive force when the conductive fluid passes through an external magnetic field. The main components of the sensor are: measuring tube, electrodes, excitation coil, iron core and magnetic yoke housing.

The following points need to be achieved in the early stage of operation of the intelligent electromagnetic flowmeter

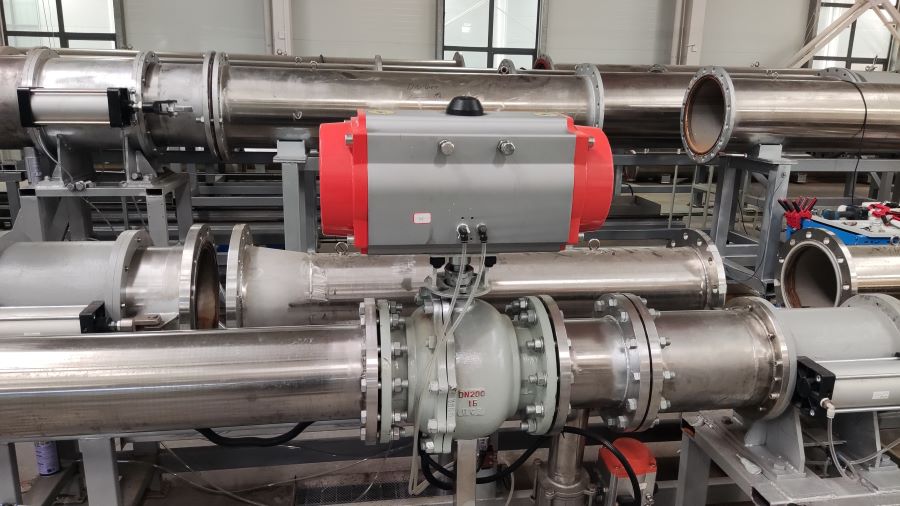

1. Install in a place free from vibration and strong electromagnetic fields (such as near large motors and frequency converters);

2. Install it as vertically as possible. If installed horizontally, it should be installed at a lower position and not at the top of the pipe to ensure full pipe coverage and prevent air bubbles.

3. Requirements for straight pipe sections: It is advisable to ensure that the first 10 and the last 5 times the pipe diameter.

4. When installing by welding, be careful not to connect the instrument for welding to prevent damage to the electromagnetic flowmeter.

5. The casing should be grounded as much as possible, and the shielded wire should be grounded at one end. The connection point must not share the ground with the strong current.

7. If it is for the convenience of maintenance, the installation location needs to be carefully selected to meet the maintenance requirements. At the same time, a bypass pipe can be installed. In case of a fault, the fluid will flow through the bypass pipe.

8. Avoid direct sunlight and high-temperature areas, as it may demagnetize.

9. Other requirements that should be considered: Signal routing should not be combined with strong current lines.