Advantages of electromagnetic flow meters compared with other meters

Compared with other flow measuring instruments, electromagnetic flowmeters have the following outstanding advantages

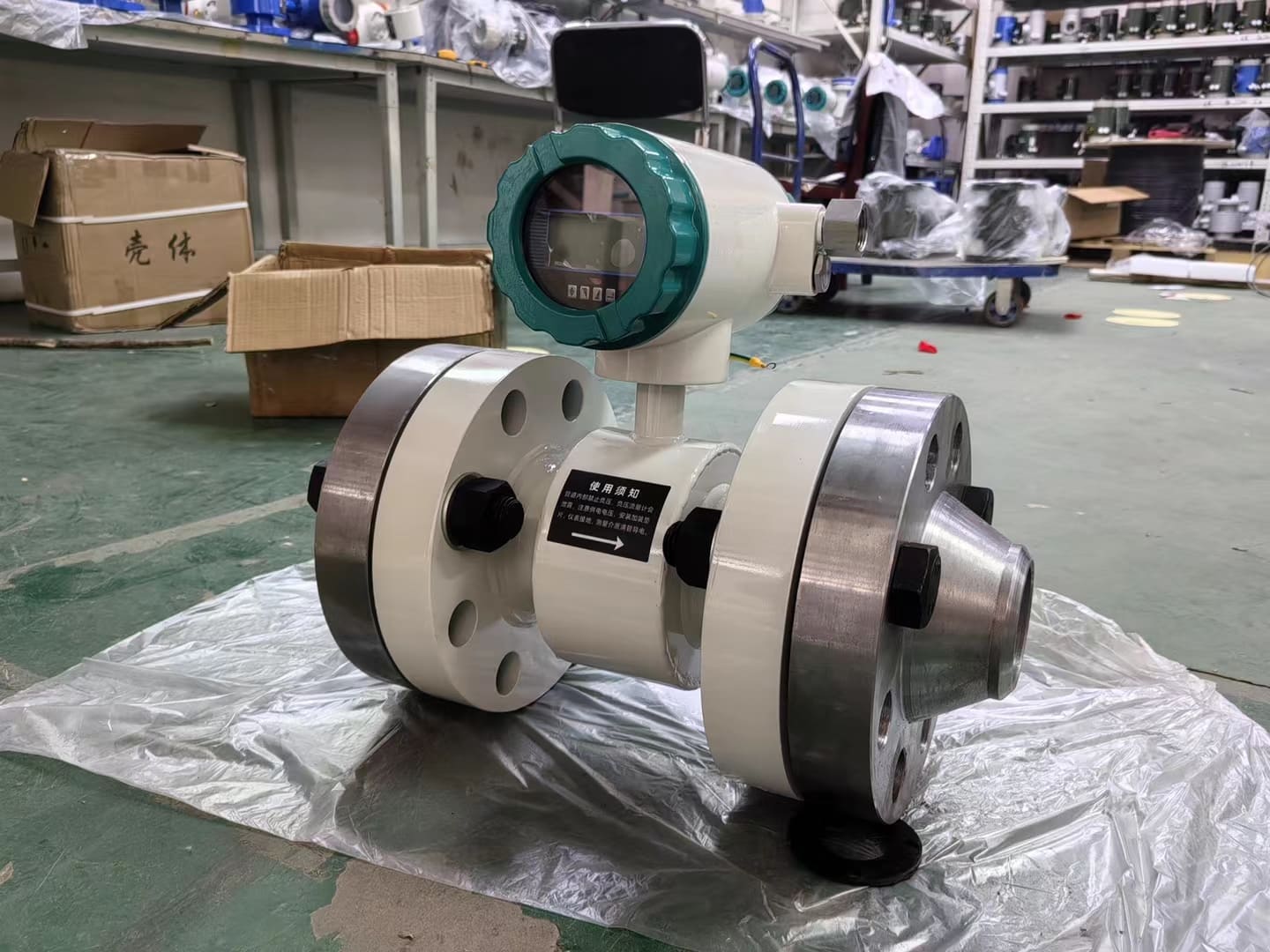

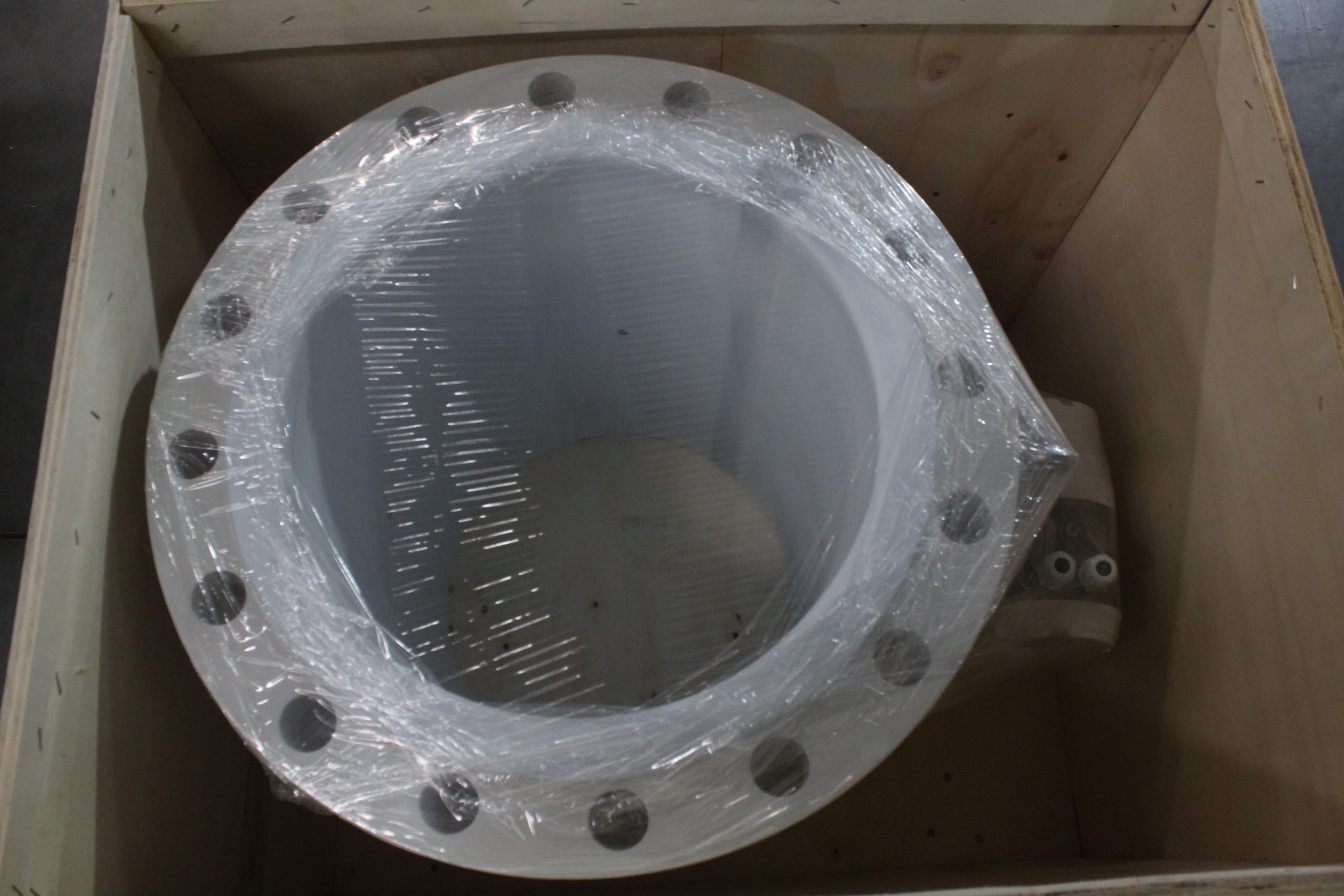

(1) Simple structure, no moving parts and disturbance or throttling parts that hinder the flow of the measured medium. Therefore, when the fluid passes through, it will not cause any additional pressure loss, saving energy and reducing consumption; At the same time, it will not cause problems such as wear and blockage, especially suitable for measuring slurry with solid particles, sewage and other liquid-solid two-phase fluids, as well as a variety of viscous grout.

(2) Only the lining and the electrode are in contact with the medium, and by selecting the corrosion-resistant insulating lining and the corrosion-resistant electrode, it can be used for the measurement of various corrosive media.

(3) Electromagnetic flowmeter is a measurement of volume flow meter, its measurement is not affected by the density of the fluid, temperature, pressure, viscosity, Reynolds number and changes in conductivity within a certain range. Electromagnetic flowmeters only need to be calibrated with water as the experimental medium, and can be used to measure other conductive liquids without additional corrections. This is an advantage that other flowmeters do not have.

(4) The range ratio is large. Same caliber sensor, full scale flow rate in the range of.03 to 15 and s arbitrary setting. The measuring range of the electromagnetic flowmeter can cover the two velocity distribution states of turbulent flow and laminar flow, which is not comparable to the differential pressure flowmeter, turbine flowmeter, vortex flowmeter and other flowmeters.

(5) The measurement principle is linear, high measurement accuracy, and complete electrical signal output, no mechanical inertia, sensitive reflection, can measure the pulsating flow rate and rapid accumulation of total.

(6) In principle, it is to measure the average flow rate of the water cross section, and the signal is integrated according to the weight distribution, and the requirements for the flow rate distribution are low. Therefore, the straight tube section before and after the sensor is required to be shorter than other flowmeters.

(7) Strong adaptability, the sensor can work for a long time diving (optional), and can measure the flow of positive and negative two directions.

-.jpg)

-.jpg)