What is the use of the ground ring of the electromagnetic flow meter?

The measuring accuracy and stability of the electromagnetic flowmeter is directly related to whether the electromagnetic flowmeter housing is grounded.

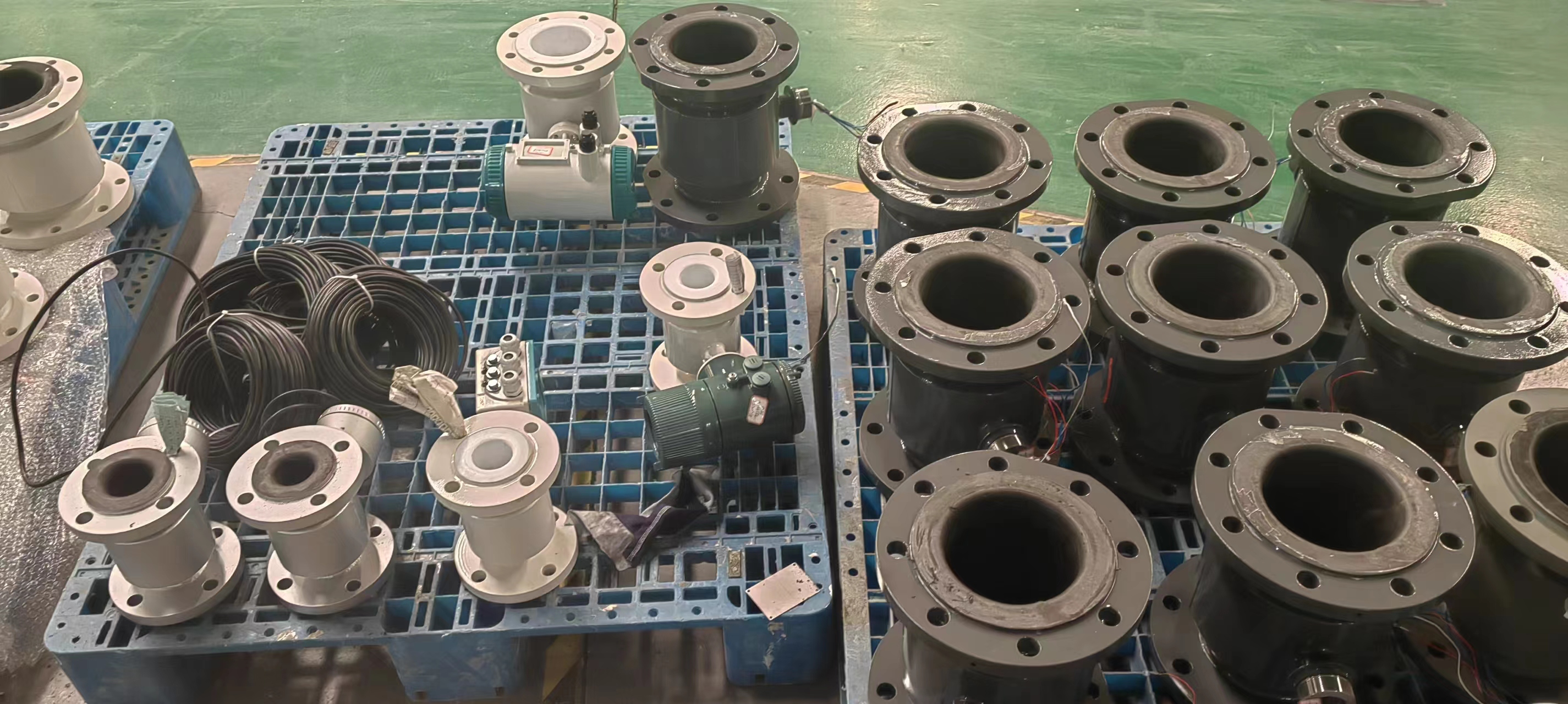

The measuring accuracy and stability of the electromagnetic flowmeter is directly related to whether the electromagnetic flowmeter housing is grounded. We all know that to ensure the measuring accuracy and stability of the electromagnetic flowmeter, we must ensure that the grounding wire of the electromagnetic flowmeter does not transmit any interference voltage. It can be seen that the grounding ring of the electromagnetic flowmeter can not be connected with other equipment on the same grounding line. Electromagnetic flowmeter in the factory when the converter output part of the ground wire is set, according to the requirements of the operation of the ground can be. Since the sensor and the metal pipe are connected, the metal pipe medium and the earth have a good electrical connection, so in addition to the docking ground has higher requirements or the working environment has a strong electromagnetic interference around the need to set the ground line alone, the sensor can not be installed with a ground line.

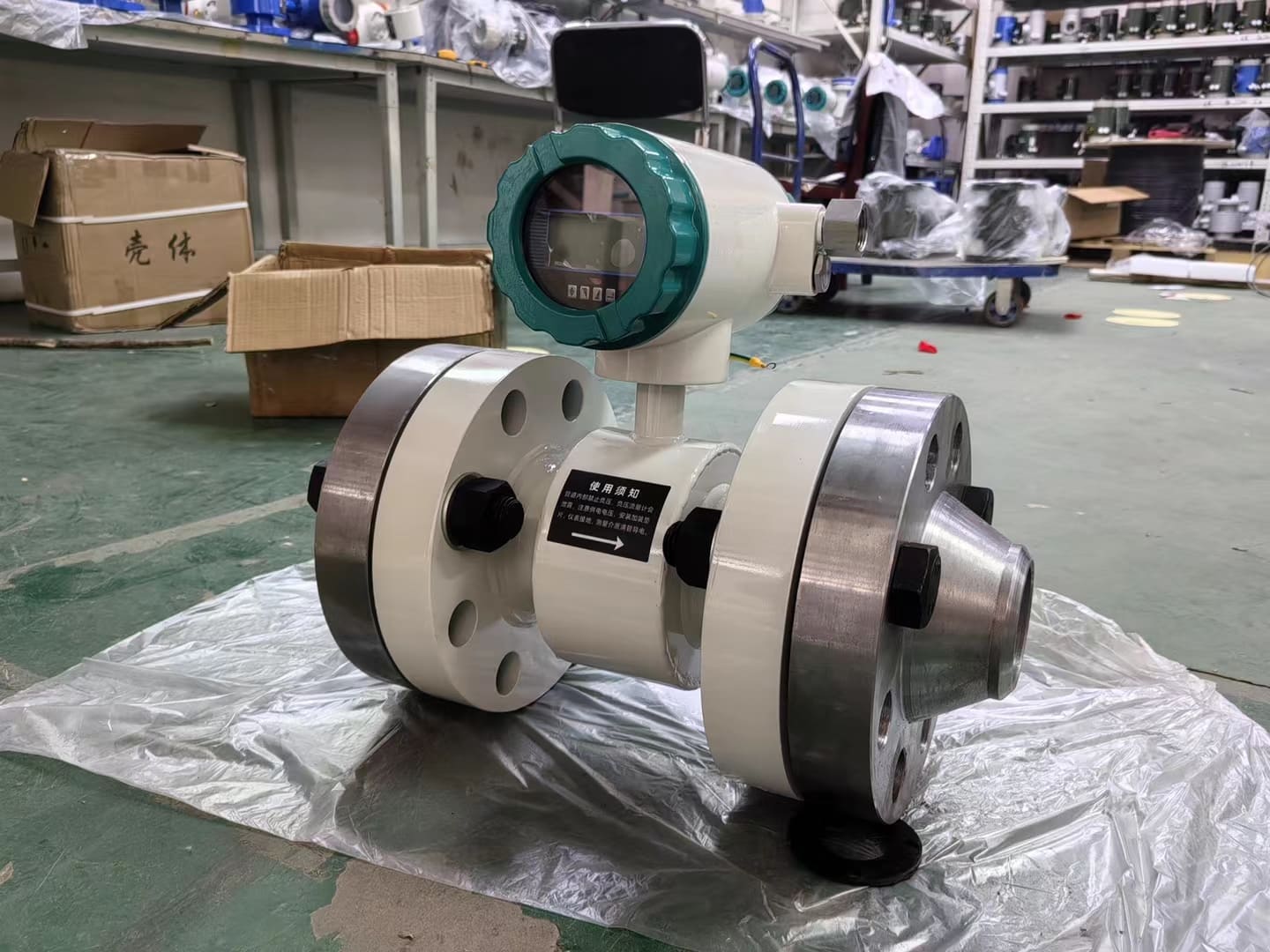

When the electromagnetic flowmeter encounters the interference of the stored current in the pipeline in the process of use, only good grounding protection can make the electromagnetic flowmeter accurate measurement. The grounding ring of the electromagnetic flowmeter does not affect its accurate measurement, and if the environmental conditions change, the electromagnetic flowmeter can not work accurately and stably. Therefore, we should do a good job in the installation of electromagnetic flow timing sensor protection, so that the electromagnetic flowmeter in a good working environment. There are many ways to ground the electromagnetic flowmeter, for example, in order to protect the lining from damage, the sensor with the tetrafluorolined can fix the ground ring with screws on the flange, and some can be connected to the sensor neck flange with a wire to connect it to the earth.

Note:

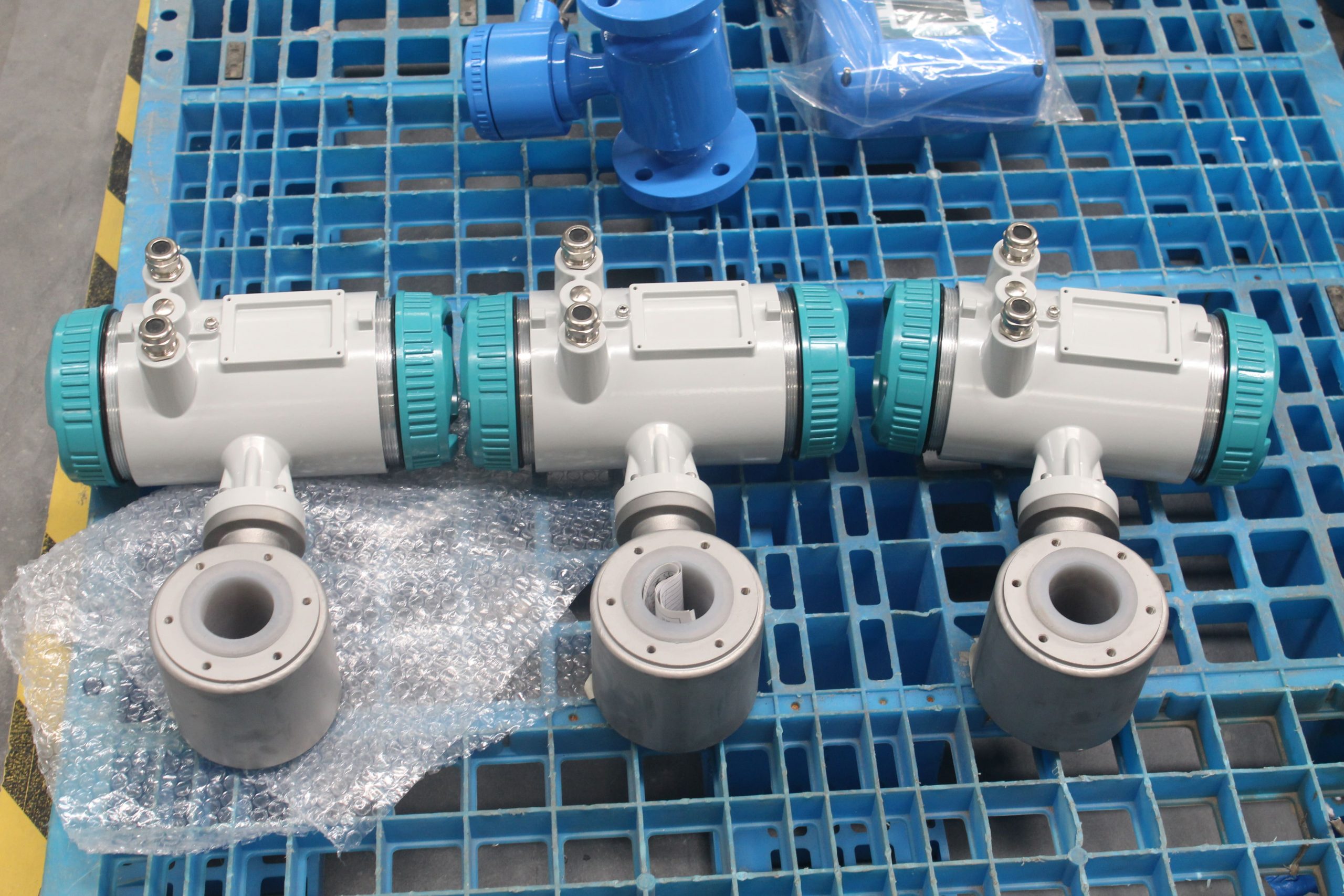

1. When the electromagnetic flowmeter is installed on the insulating coating, plastic pipe or painted pipe, in order to make the measured medium in the pipe and the ground short circuit, with zero potential, the sensor must be installed at both ends of the ground wire, otherwise the electromagnetic flowmeter can not work normally.

2. The electromagnetic flowmeter must use stainless steel as a grounding ring.

3. The ground ring of the electromagnetic flowmeter cannot be connected with the ground of other equipment, that is, the ground point must be an independent acceptance point, and the ground resistance should be less than 10Ω.