How to extend the service life of intelligent electromagnetic flowmeters

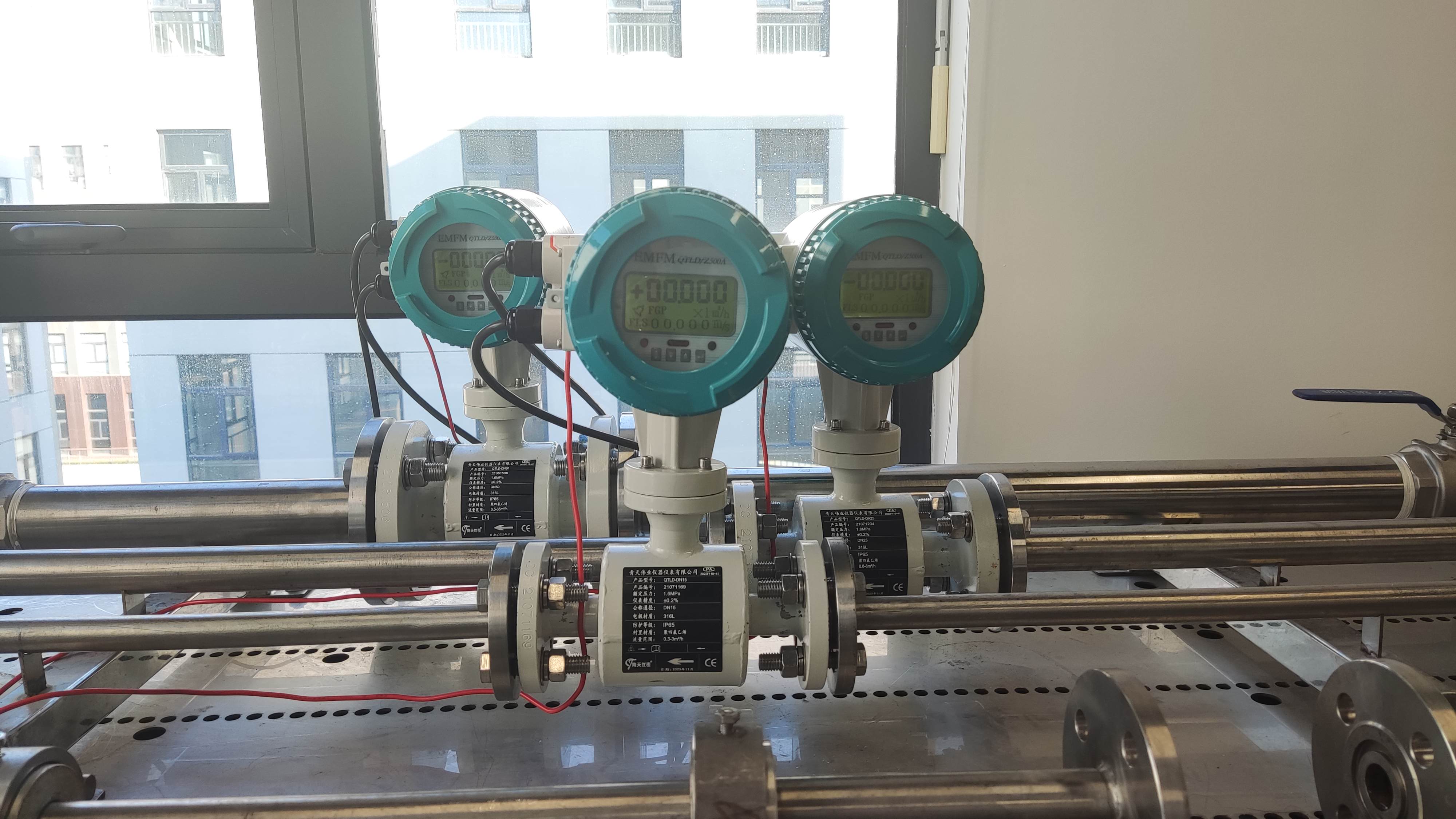

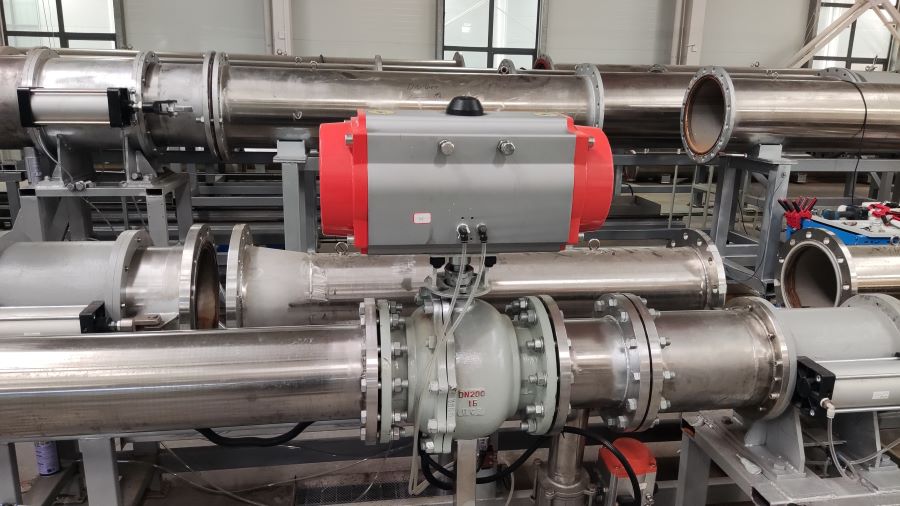

Intelligent electromagnetic flowmeters are mainly used to measure the volume flow of conductive liquid and slurry in closed pipelines, including acid, alkali, salt and other highly corrosive liquids.

Intelligent electromagnetic flowmeters are widely used in petroleum, chemical, metallurgical, textile, food, pharmaceutical, paper and other industries, as well as environmental protection, municipal management, water conservancy construction and other fields.

How to maintain long-term use of intelligent electromagnetic flowmeters:

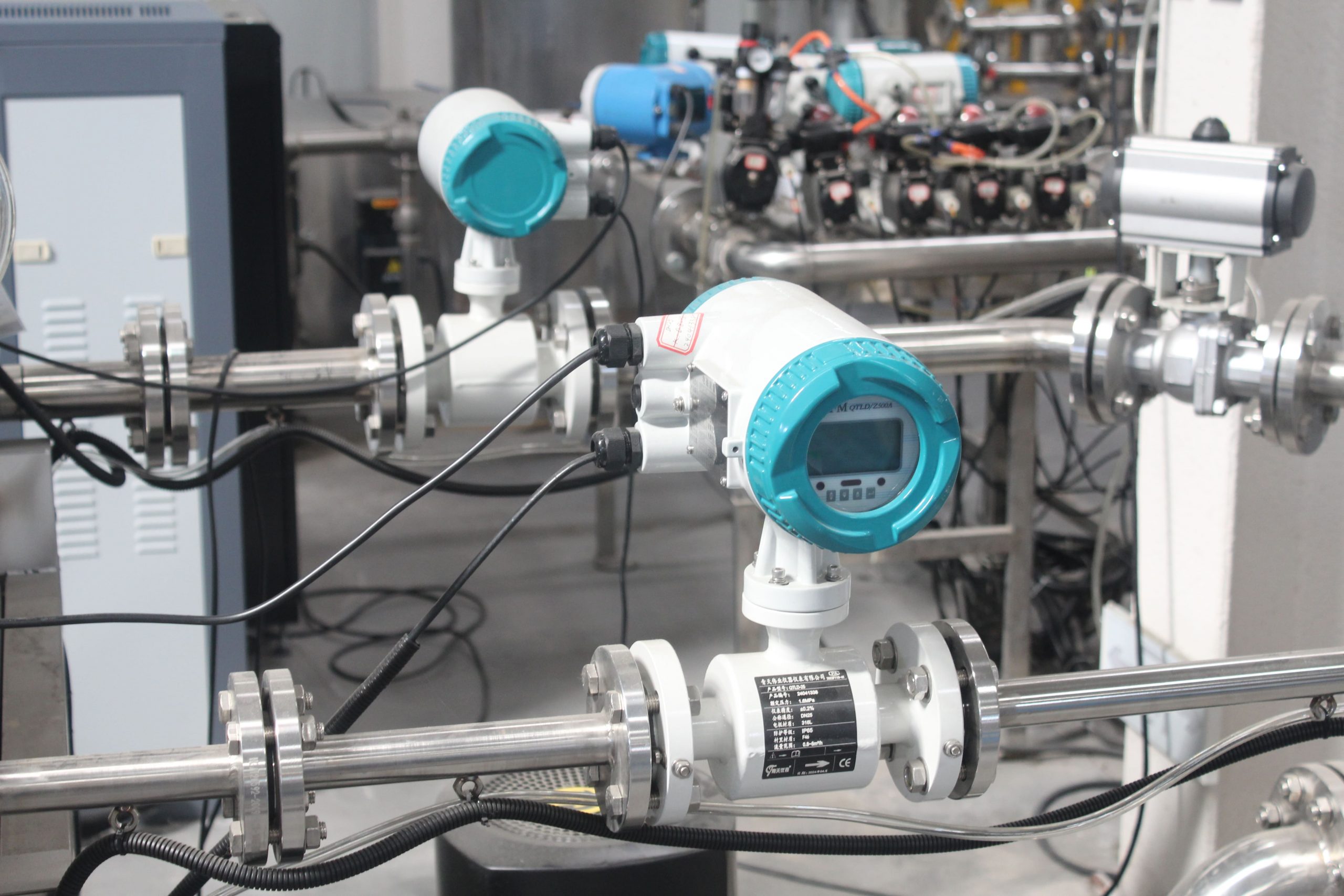

1, ensure that the wiring is stable: in the wiring process, ensure that the wire connection is firm and reliable, and the necessary fixing to prevent loosening or contact.

2, to prevent interference: In order to avoid the interference of external electromagnetic fields on the electromagnetic flowmeter signal, the cross-wiring of signal lines and power lines, control lines, etc. should be reduced as much as possible, and shielding measures should be taken, such as the use of shielded cables.

3, to prevent the impact of temperature: in the use of electromagnetic flow timing at high or low temperatures, you need to pay attention to the selection of wires and terminals that adapt to the temperature range to ensure their normal work.

4, lightning protection: lightning protection devices should be installed in thunderstorms or areas vulnerable to lightning strikes to protect the electromagnetic flowmeter from lightning damage.

5, grounding treatment: for places prone to electromagnetic interference, such as near the power transformer, appropriate grounding measures should be taken to reduce interference and improve the accuracy of measurement.

6, regular inspection: In order to ensure the long-term stability of the electromagnetic flow meter, it is recommended to regularly check the fastening and insulation performance of the terminal, and timely discover and deal with possible problems.

When connecting cables, connect power cables, signal cables, and ground cables in the correct sequence and pay attention to the details, such as anti-interference protection, lightning protection, and grounding. In addition, regular inspection and maintenance is also an important part of ensuring the long-term stability of the electromagnetic flowmeter. Only reasonable and correct wiring and maintenance, in order to give full play to the function of the electromagnetic flowmeter, to achieve measurement and automatic control.