Regarding the requirements for the external environment of insertable electromagnetic flowmeters

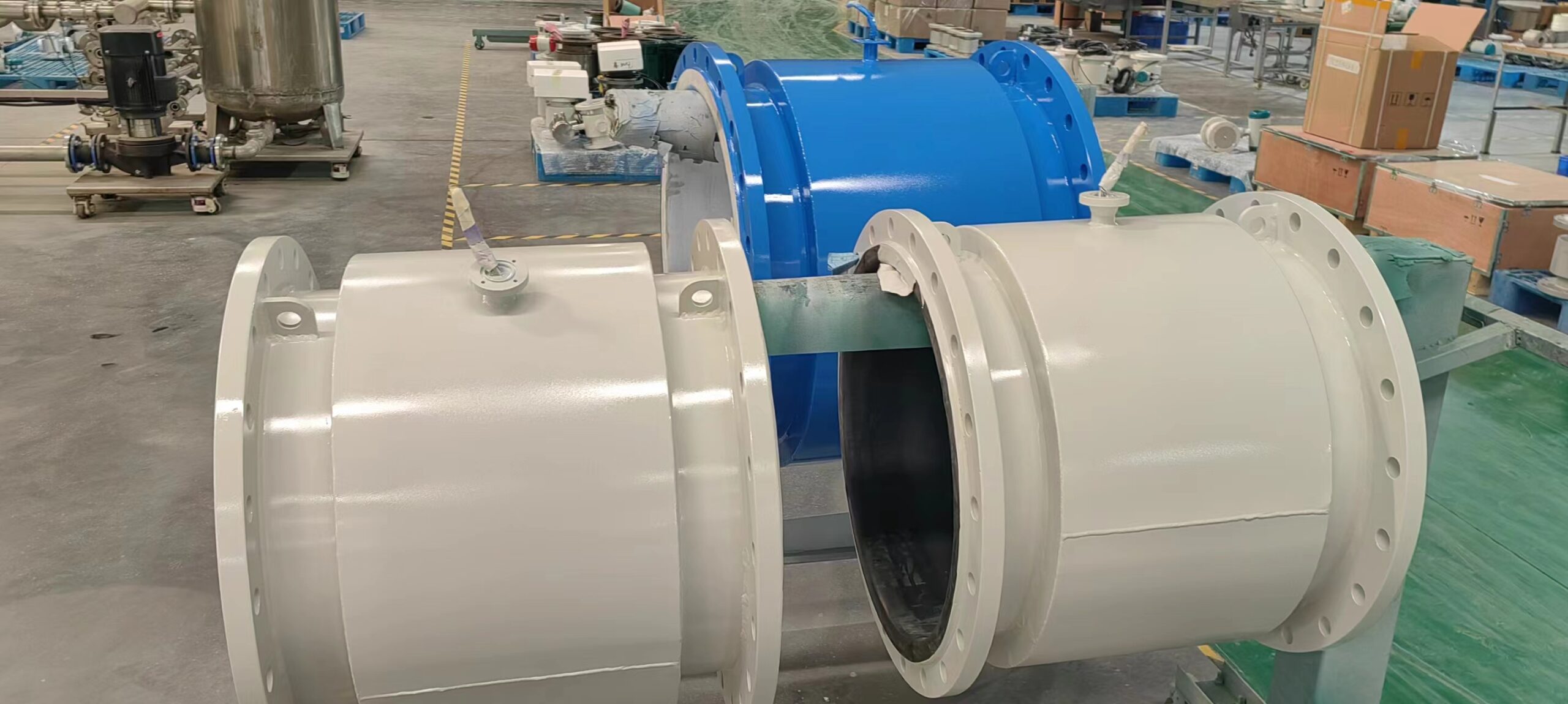

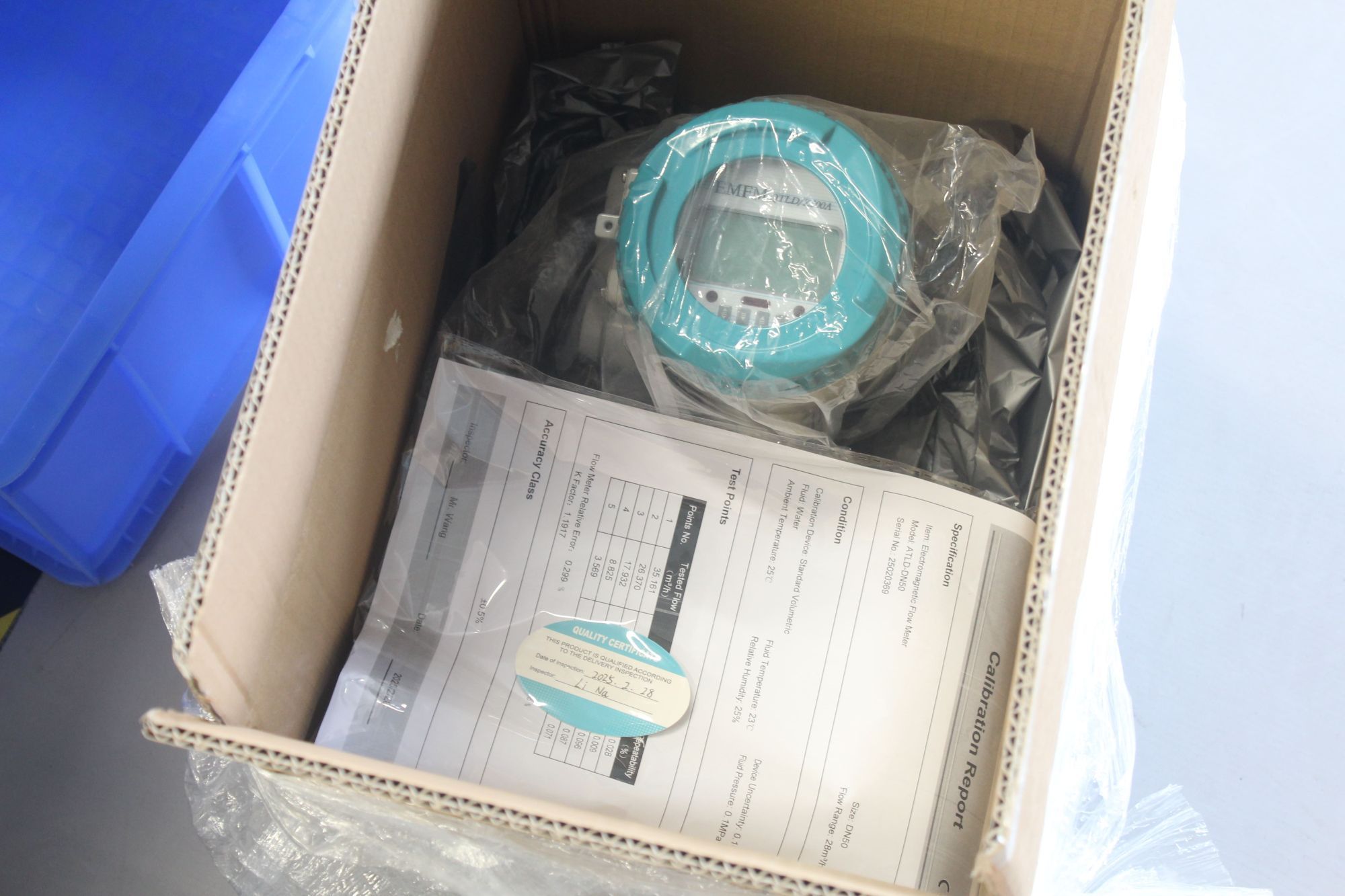

The insertable electromagnetic flowmeter is an instrument for measuring conductive liquids made based on Faraday’s law of electromagnetic induction. This type of instrument, due to its simple structure, light weight, easy installation and low maintenance requirements, is used to measure the volume flow of non-corrosive (for water supply and drainage) conductive liquids in closed pipelines.

Requirements for the external environment of insertable electromagnetic flowmeters:

1. It should be avoided to be installed in places with large temperature fluctuations or exposed to high-temperature radiation from equipment. If installation is necessary, measures for heat insulation and ventilation must be taken.

2. It should be installed indoors. If it must be installed outdoors, it should be protected from rain, water accumulation and direct sunlight. Moisture-proof and sun protection measures must be taken.

3. It should be avoided to be installed in an environment containing corrosive gases. If installation is necessary, ventilation measures must be taken.

4. To facilitate installation, maintenance and upkeep, there should be sufficient installation space around the flowmeter.

5. The installation site should avoid magnetic fields and strong vibration sources. If the pipeline vibrates greatly, there should be supports on both sides of the flowmeter to fix the pipeline.

Installation and usage instructions for the insertable electromagnetic flowmeter

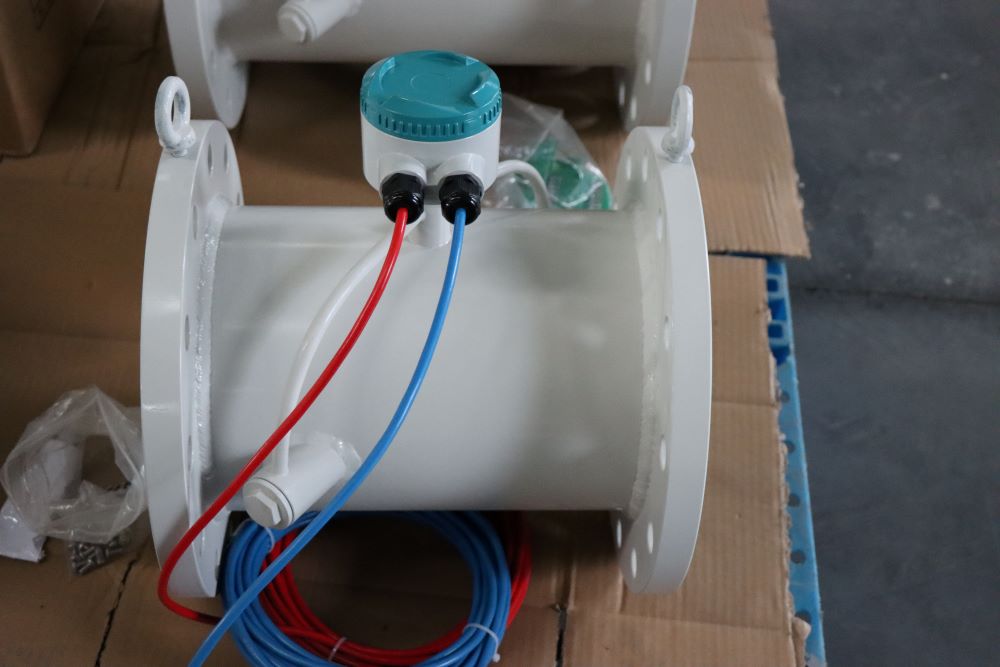

It can be installed either indoors or outdoors. If it is installed in a ground well and there is a possibility of flooding, submersible sensors or transmitters should be selected.

2. It can be installed horizontally, vertically or at an Angle on the pipeline, but when measuring liquid, the pipeline must be filled with liquid. Therefore, when installing vortex flowmeters on vertical or inclined pipes, the flow direction of the liquid should be from bottom to top.

3. Long straight pipe sections should be reserved on both the upstream and downstream sides. The length of the straight pipe sections upstream and downstream should vary according to the different conditions of the pipeline. The installation of control valves or half-open valves upstream should be avoided as much as possible. Control valves or half-open valves should be installed 5D downstream of the flowmeter.

4. The inner diameter of the installed pipeline must be consistent with that of the flowmeter; otherwise, the pipeline must be reduced in diameter.

5. When designing pipeline installation, space should be left at the upper end of the sensor or transmitter amplifier to facilitate commissioning and maintenance.

-.jpg)