3 special testing contents to ensure the normal operation of electromagnetic flow meters

Due to various reasons, some large diameter flowmeters used online can not be tested off-line. It has become an urgent problem to study an online calibration method which is both scientific and effective and ADAPTS to the needs of the field. At present, there are three common methods for online calibration of electromagnetic flowmeters:

Liquid level drop method

Using the pool as a measuring vessel, the volume is calculated by measuring the water level of the pool, and the flowmeter is calibrated. Before calibration, it is necessary to determine whether there is an unknown pipeline between the calibrated flowmeter and the pool, and the pool construction should ensure a certain accuracy, otherwise the calibration results will be large error.

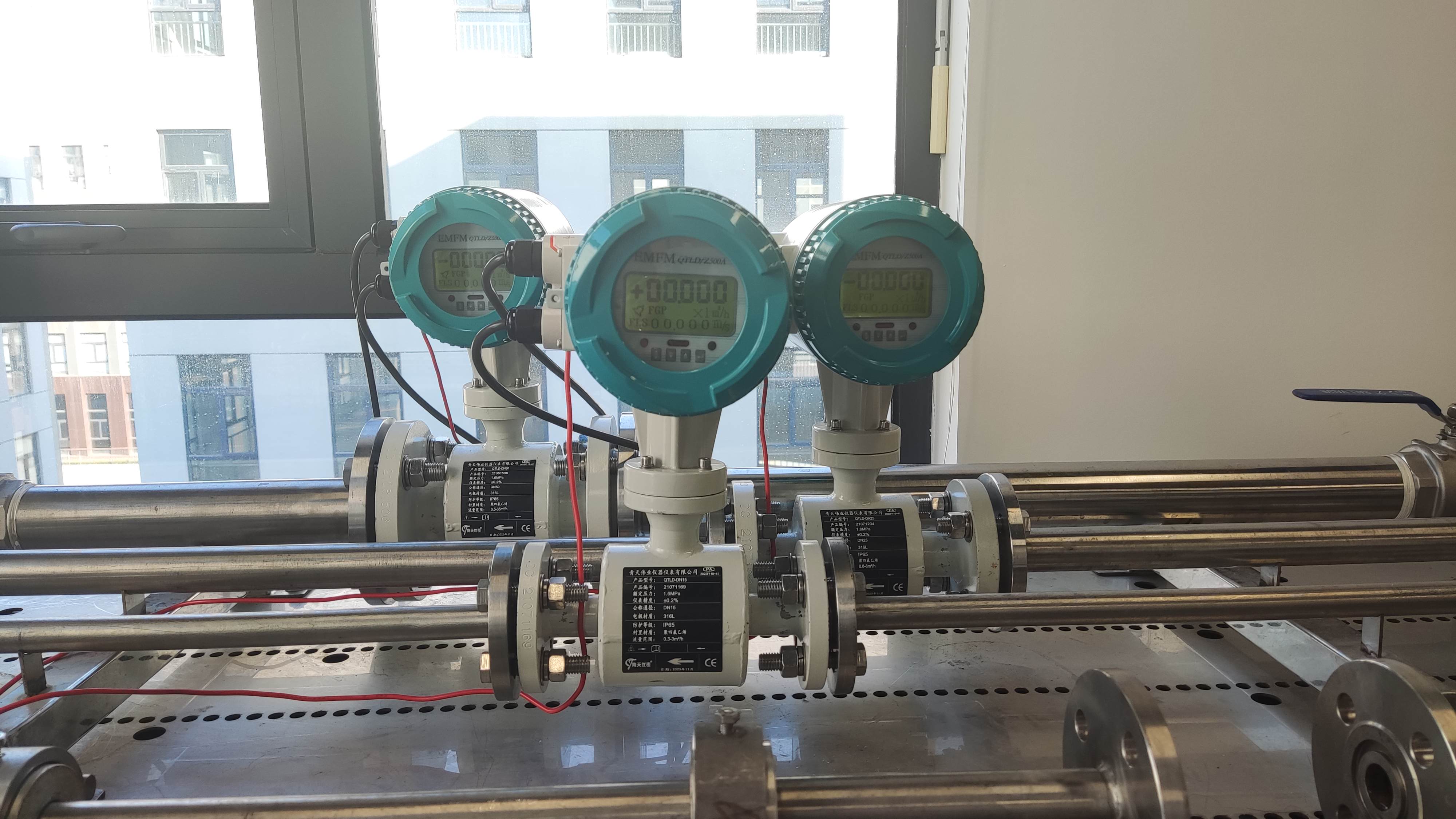

On-line comparison method

The ultrasonic flowmeter is used as the standard meter, and the flowmeter is connected in series. The accuracy of the flowmeter is determined by comparison. When using, it should be noted that the standard table needs to have a valid verification certificate, and pass the measurement standard examination to obtain the social public measurement certificate; The site conditions should meet the requirements, and the calibrator should operate in strict accordance with the specifications.

Method of detecting electrical parameters

Connect the testing equipment with the on-line calibrated flowmeter, and determine whether the flowmeter meets the use requirements through testing and analysis. This method can detect both inside and without water in the pipeline, but only electromagnetic flowmeters can be detected.

-.jpg)