Electromagnetic flow meter installation specification

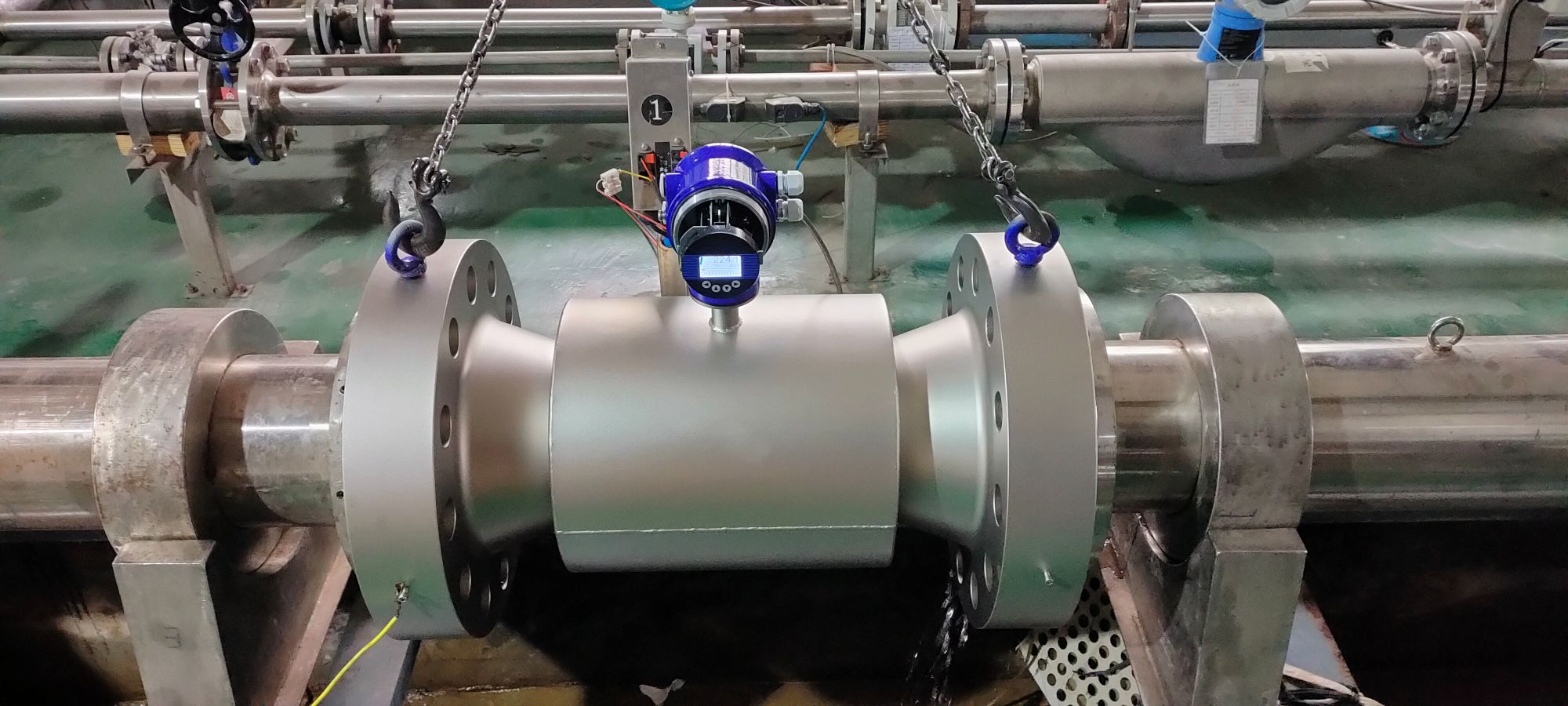

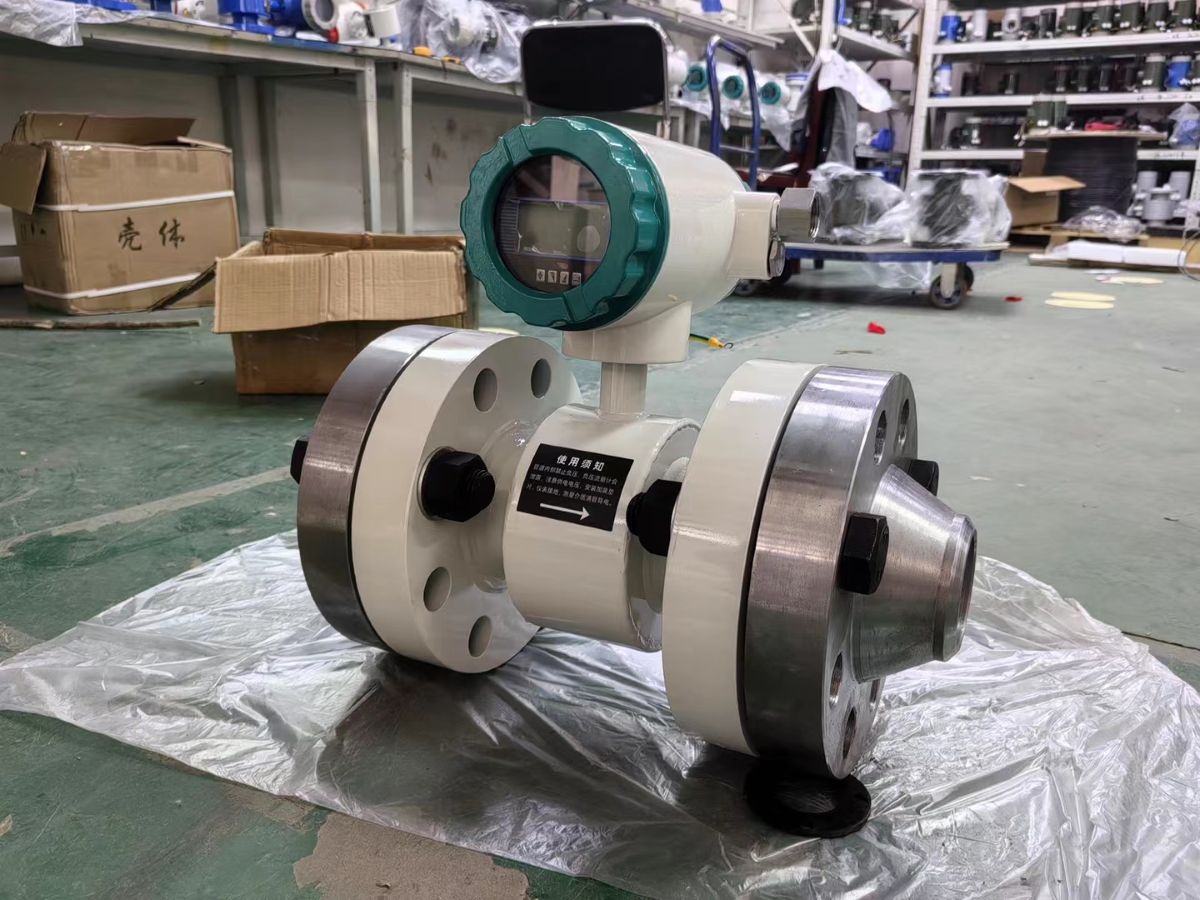

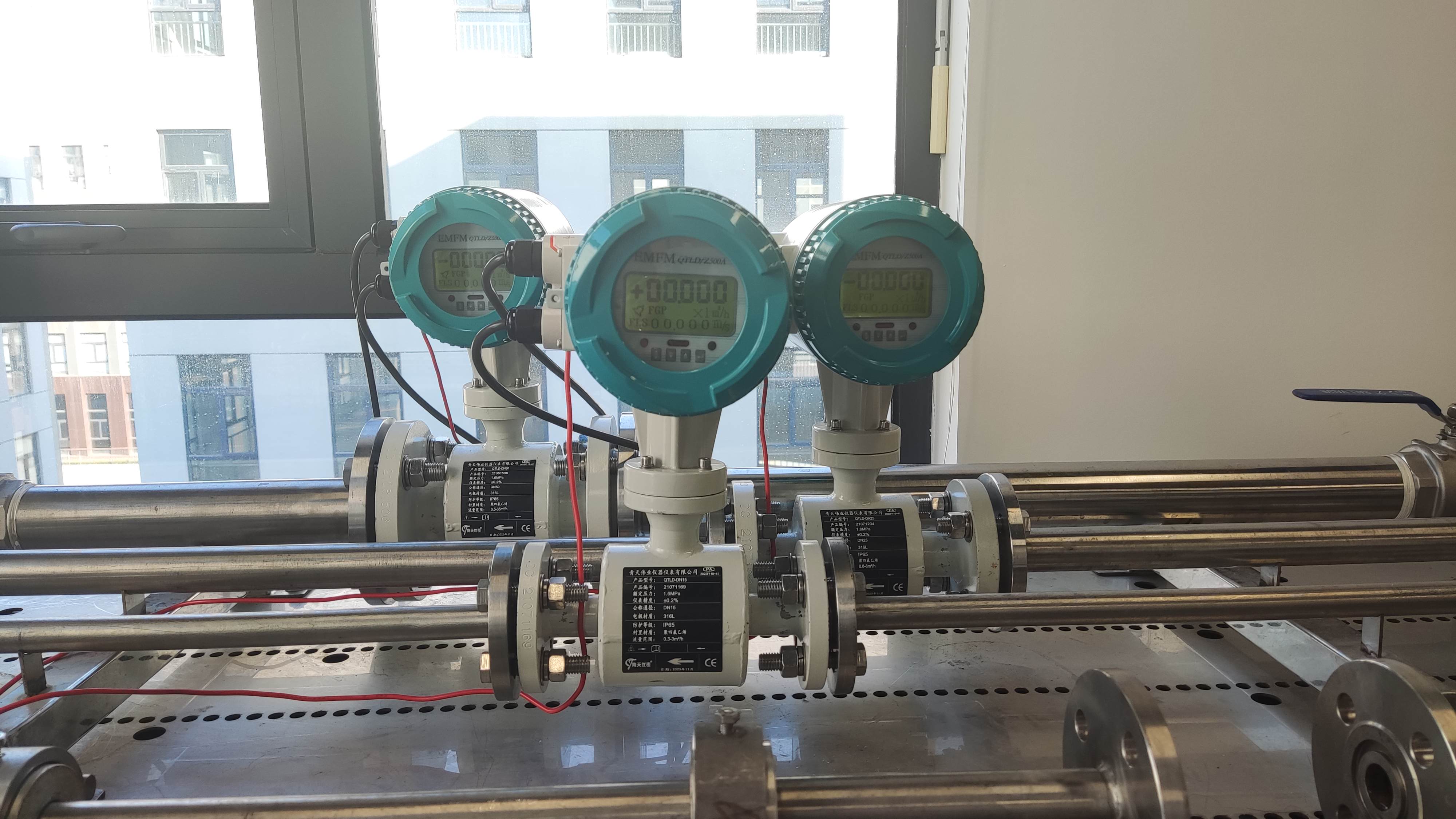

Electromagnetic flowmeter mainly has two kinds of pipe segment type and plug-in type, and is divided into two types of body type and sub-body type, of which the plug-in electromagnetic flowmeter is suitable for DN300 or more pipelines.

Electromagnetic flowmeter installation specifications mainly have the following points:

1, if the pipeline is in the high air or underground instrument well, it is recommended to choose the partial type electromagnetic flowmeter.

2. The installation position of the instrument on the pipeline should be far away from the valve, and the straight pipe section of 10 times the diameter of the upstream pipe and the straight pipe section of 5 times the diameter of the downstream pipe should be maintained.

3, the field power supply must match the instrument power supply, generally 24V DC power supply. If the measurement is in the field and there is no external power supply on site, the battery-powered electromagnetic flowmeter is used.

4. Pay attention to the flow direction of the measured liquid in the pipeline. If the installation is reversed, the measurement result will be negative.

5, the installation site of the electromagnetic flowmeter should choose the place of shade and rain, such as often wet or soaked in water, you should choose the protection level of IP68 products.

6, the management personnel should regularly check and maintain the electromagnetic flowmeter to ensure the normal operation of the instrument and timely treatment of problems. If you cannot solve it yourself, please contact Aister in time and we will help you solve it.

-.jpg)