9 advantages of battery-powered electromagnetic flow meters

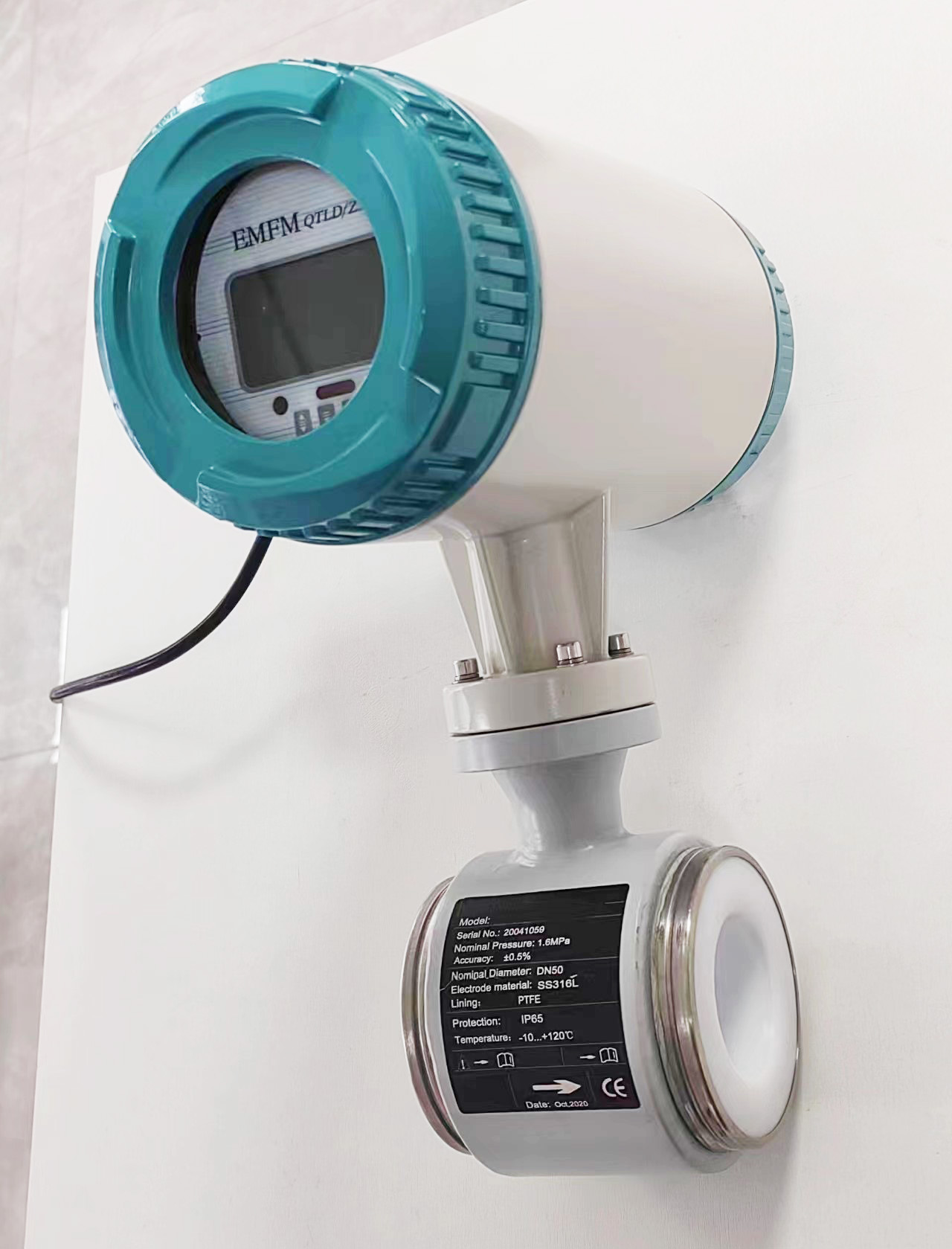

Battery-powered electromagnetic flowmeter is a metering instrument designed for water supply enterprises, which can optimize water use and ensure accurate water measurement.

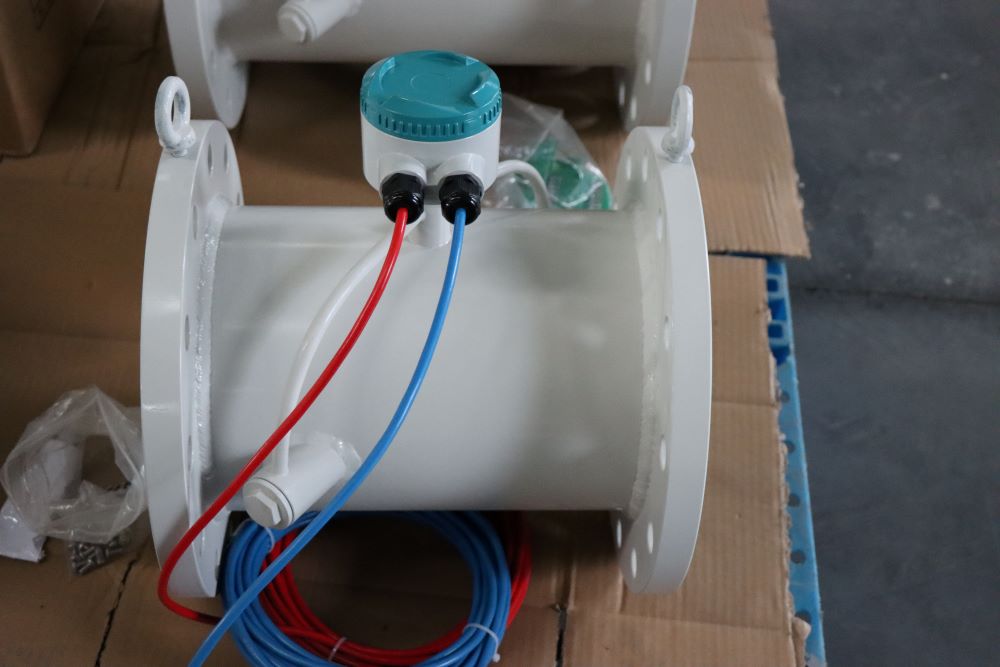

1, micro-power design, five 3.6V lithium batteries, continuous work for 5 to 10 years, and easy to replace the battery.

2, the display adopts LCD large-screen liquid crystal display, which can display a number of flow parameters such as instantaneous flow rate, flow rate, positive and negative cumulative total and alarm prompt.

3, no moving and resistance parts in the measuring tube, no entanglement, blockage phenomenon, almost no pressure loss, can be long-term reliable continuous work.

4, Wide measuring range, flow rate measuring range up to 0.05m/s~10m/s.

5, the measurement is stable, the measurement accuracy is not affected by the change of physical parameters such as temperature, pressure, viscosity and density of the measured medium.

6, with pulse output and GSM wireless data transmission function.

7, with data storage function, can save up to 1000 groups of traffic data, and data storage time interval can be arbitrarily set and data query.

8, a wide range of applications, can be used in sewage treatment, water conservancy projects, urban water supply and other fields.

9, stable work, high measurement accuracy, strong anti-interference ability.

-.jpg)

-.jpg)