What are the power supply modes of electromagnetic flow meter?

Electromagnetic flowmeter has become one of the flow meters for measuring media in chemical enterprises. As long as the liquid has a certain conductivity, the electromagnetic flowmeter can be used to stop the flow measurement.

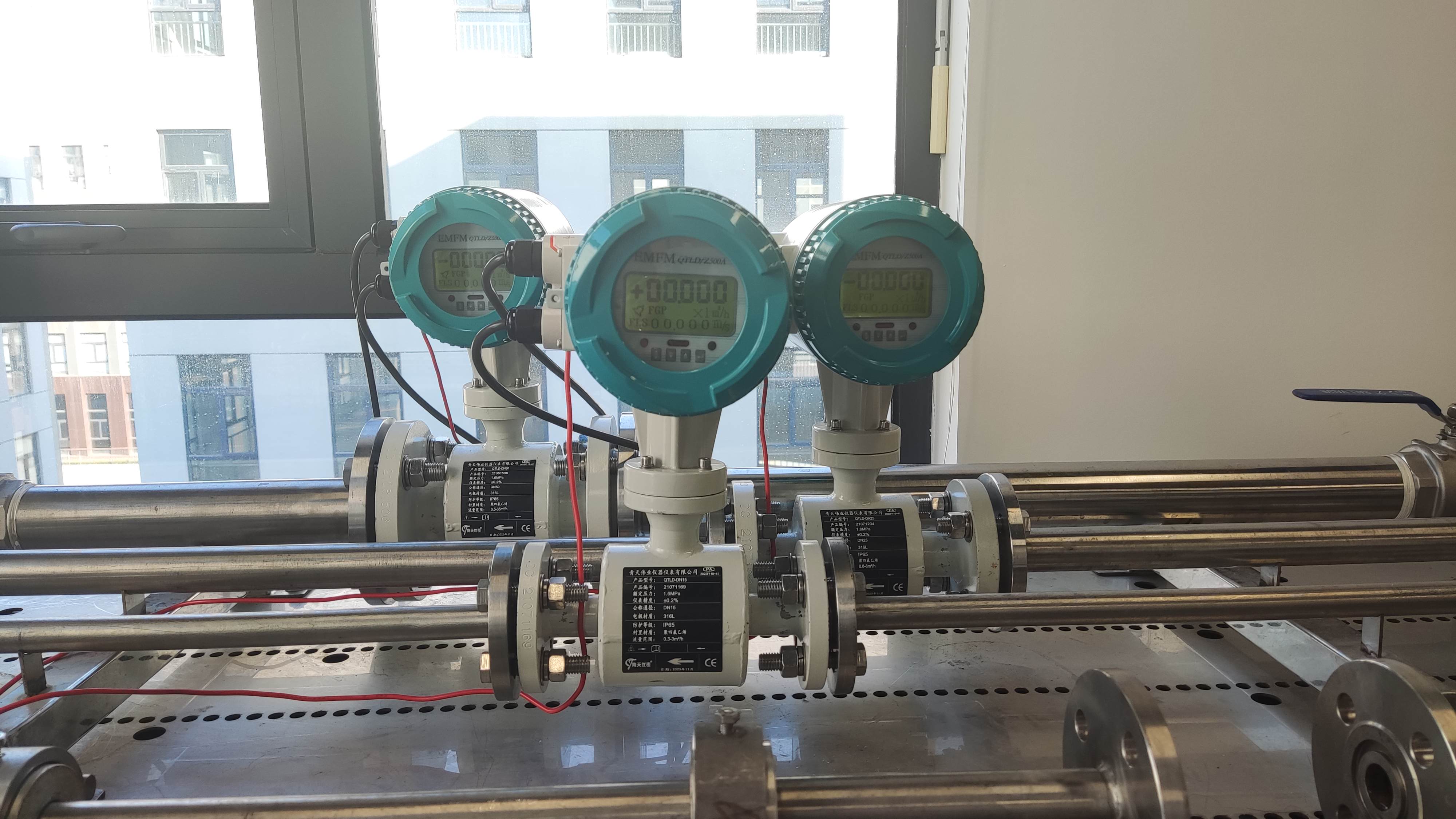

Electromagnetic flowmeters are used more in water, sewage, sulfuric acid, ammonia and other conductive liquids. Electromagnetic flowmeter is different from the volume of the flowmeter, the operation of the electromagnetic flowmeter depends on the supply of power, the needle on different working conditions, the power supply method of the flowmeter now has three kinds, respectively, 220V AC power supply, 24V DC power supply and battery (high-function lithium battery) power supply.

1. 220V power supply, electromagnetic flowmeter is now used a lot, the general industrial site has 220V power supply, the flowmeter only needs to stop the equipment according to the request, no need to install other equipment, on the power can stop the operation. 220V power supply electromagnetic flowmeter can be made into one type or split type.

2. 24V power supply electromagnetic flowmeter is used in industrial sites where communication electricity is not allowed to be used or low voltage direct current is considered from the safety aspect, or the flow distribution integrator is powered by the integrator to the electromagnetic flowmeter.

3. Battery power supply is made of battery power in the case of no external power supply at the scene, or in the case of safety considerations at the scene, instantaneous flow can be flashed at the scene, cumulative flow can save the cost of dragging the power supply, and this battery power supply method is particularly important in a more remote environment.

-.jpg)

-.jpg)