Sewage flow meter selection

The selection of flow meters should consider many factors, such as diameter size, medium flow, pressure, density, fluid flow state, installation environment, etc., so how to choose a large number of sewage flowmeters?

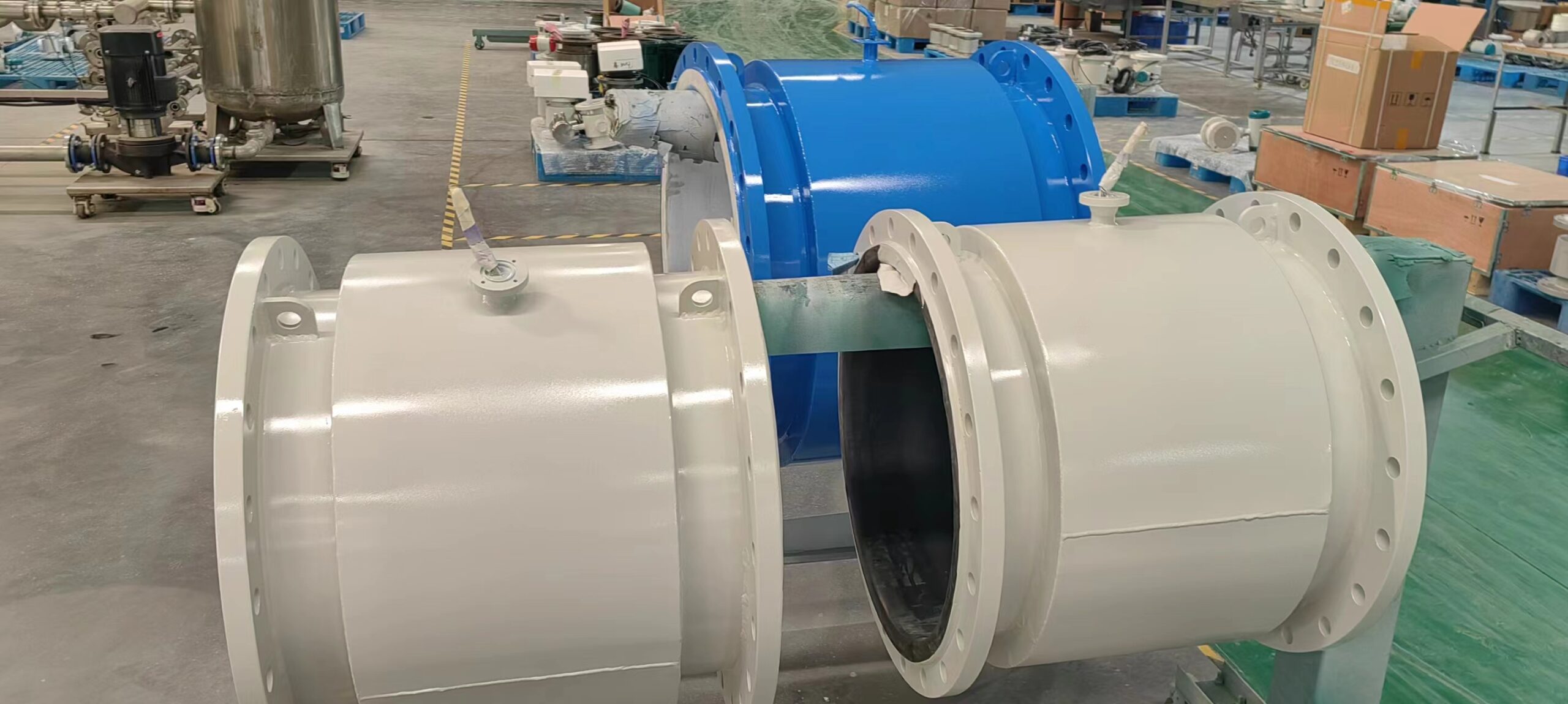

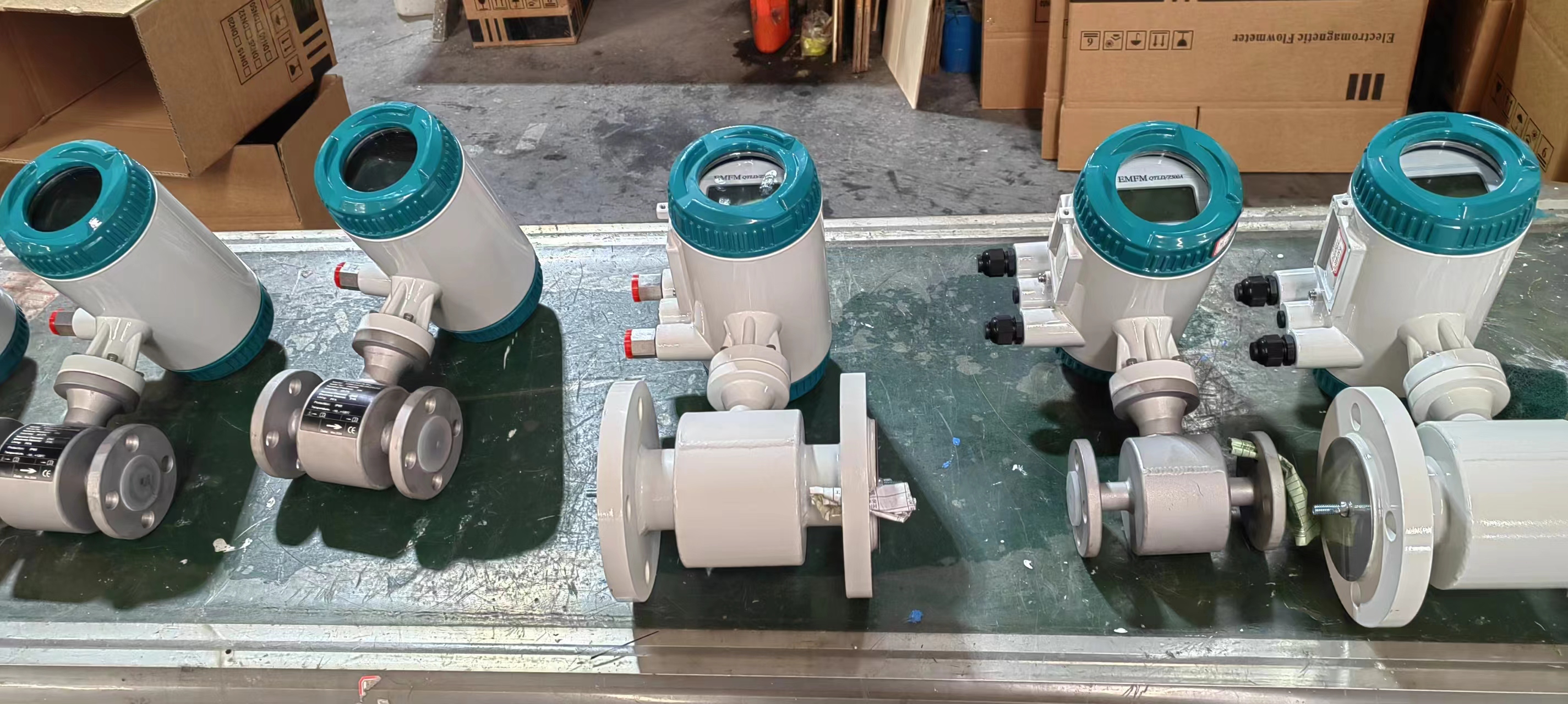

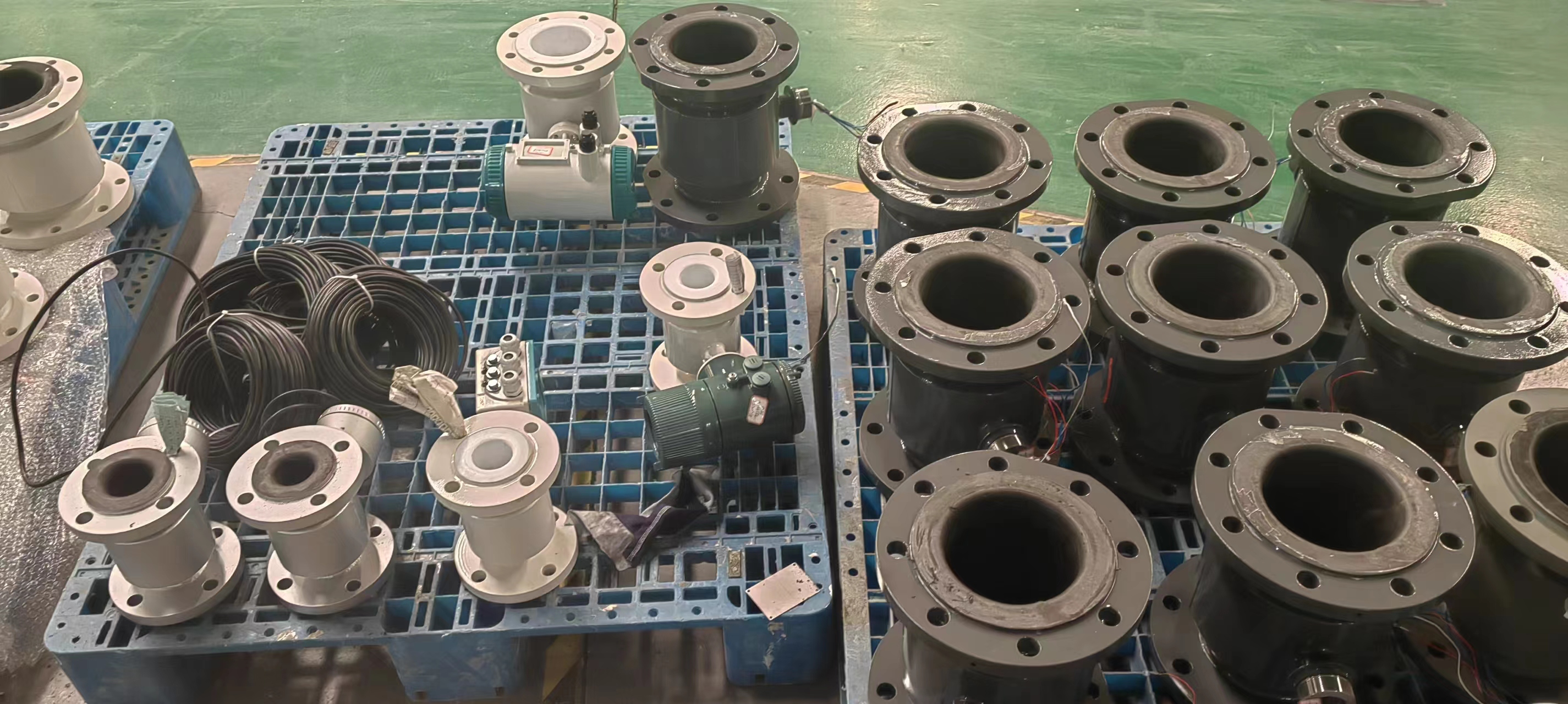

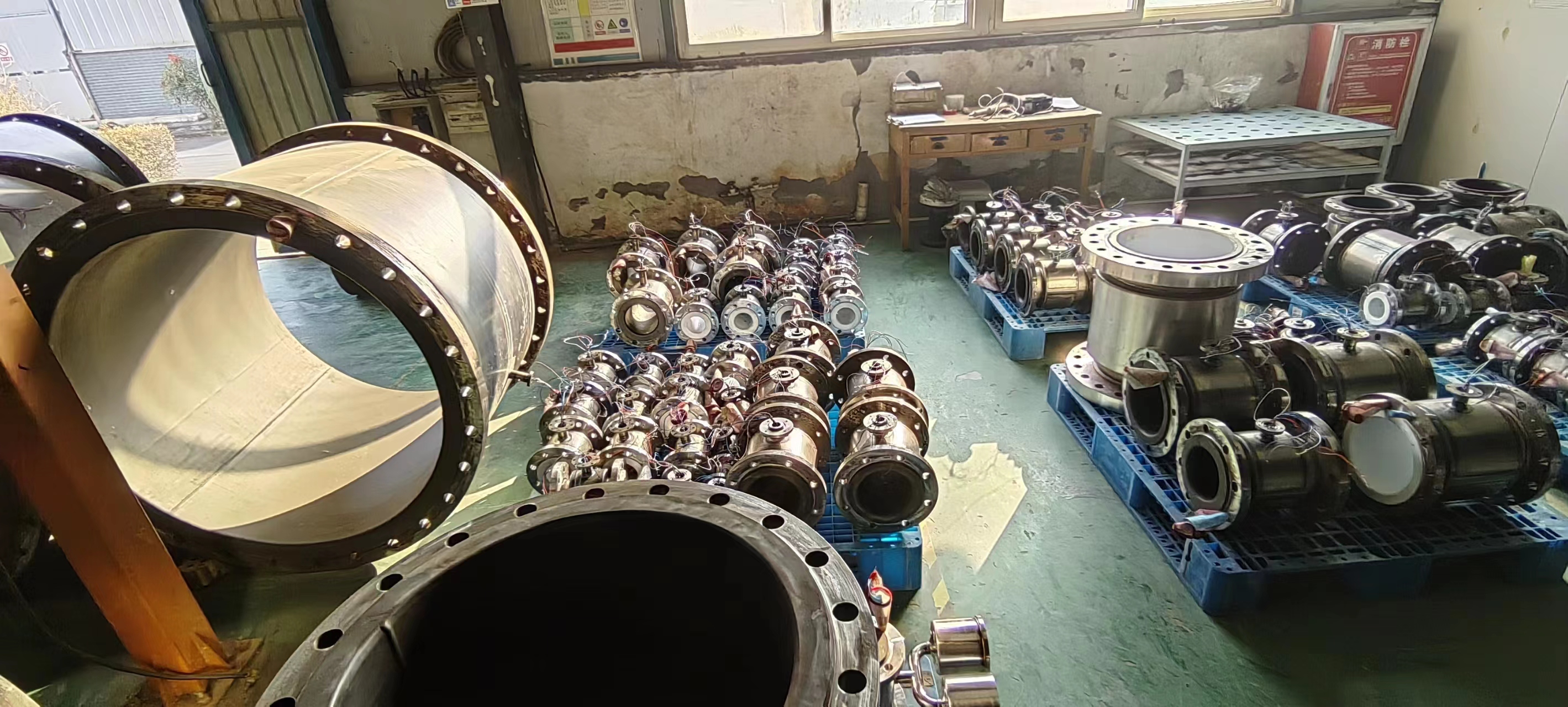

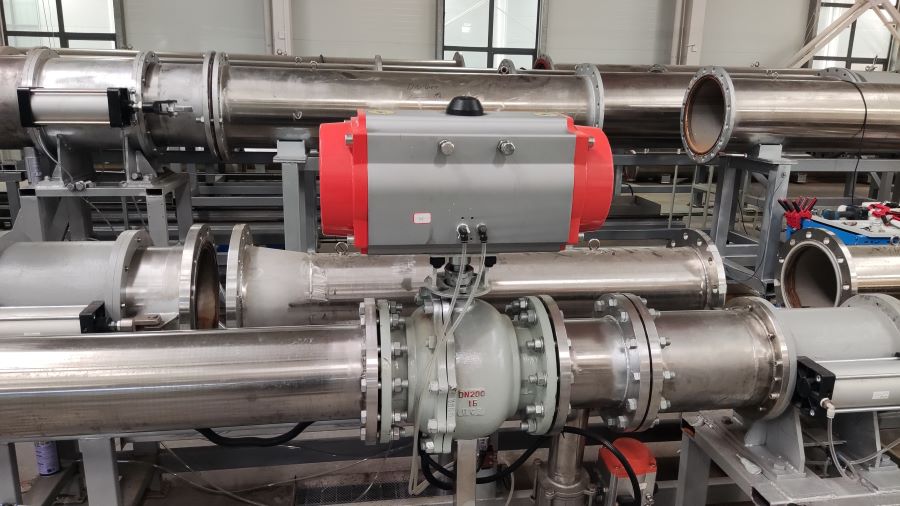

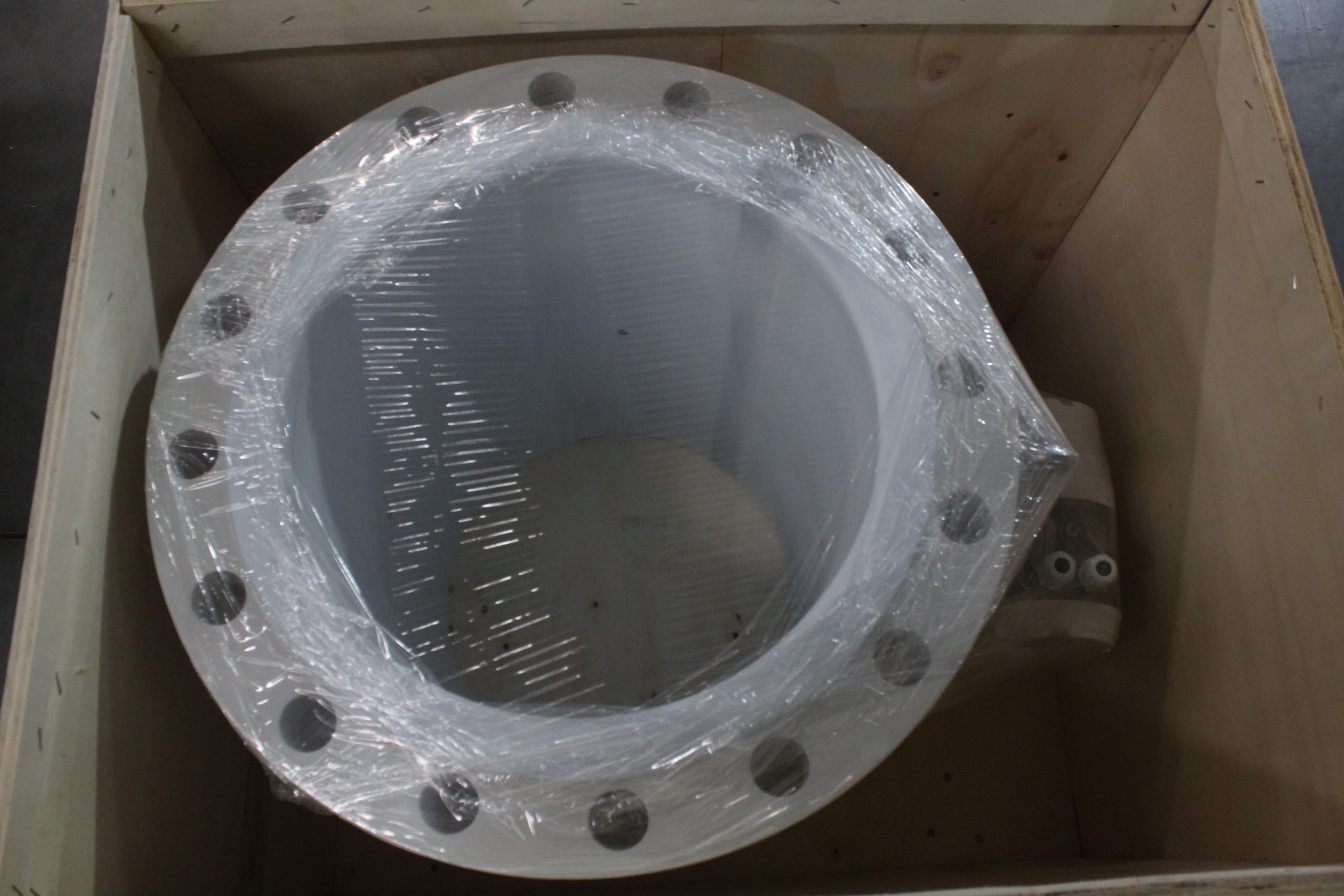

1. Electromagnetic flowmeter

Industrial sewage flow rate changes, contains more impurities, has a certain corrosiveness, can conduct electricity, electromagnetic flowmeter is a good choice. It has no internal choke parts, no pressure loss, strong corrosion resistance and anti-interference ability, installation, operation and maintenance are very convenient, is a relatively ideal sewage flowmeter.

2. Ultrasonic open channel flowmeter

The ultrasonic flowmeter is used in combination with the Basher tank to measure the flow of water in the open channel. It is mainly used for measuring sewage plants, enterprises and institutions of the sewage discharge outlet, urban sewer flow and irrigation channels. It uses ultrasonic waves through the air to measure in a non-contact way, which is more reliable than other forms of meters in the case of sticky, corrosive liquids.

3. Electromagnetic flowmeter, ultrasonic open channel flowmeter difference

Electromagnetic flowmeter can measure almost all conductive liquids, no internal choke parts, no pressure loss, large measurement range, anti-interference, anti-impurity ability, in the measurement is not affected by the temperature, pressure, density and viscosity of the fluid.

Ultrasonic open channel flowmeter is very wide, the use of acoustic waveguide technology, can withstand a variety of extreme process conditions, can be applied in a harsh environment, but it is easy to be affected by temperature, radiation, etc., improper installation or use will seriously affect its measurement accuracy and service life.

Summary: Which of these two flowmeter Spaces is more suitable for sewage measurement, it needs to be combined with the actual use of the environment to decide. If you have any questions about the flow meter selection, please consult Aister Meter or email sales@aistermeter.com for help.