Detailed Explanation of the Advantages and Disadvantages of Ultrasonic flowmeters

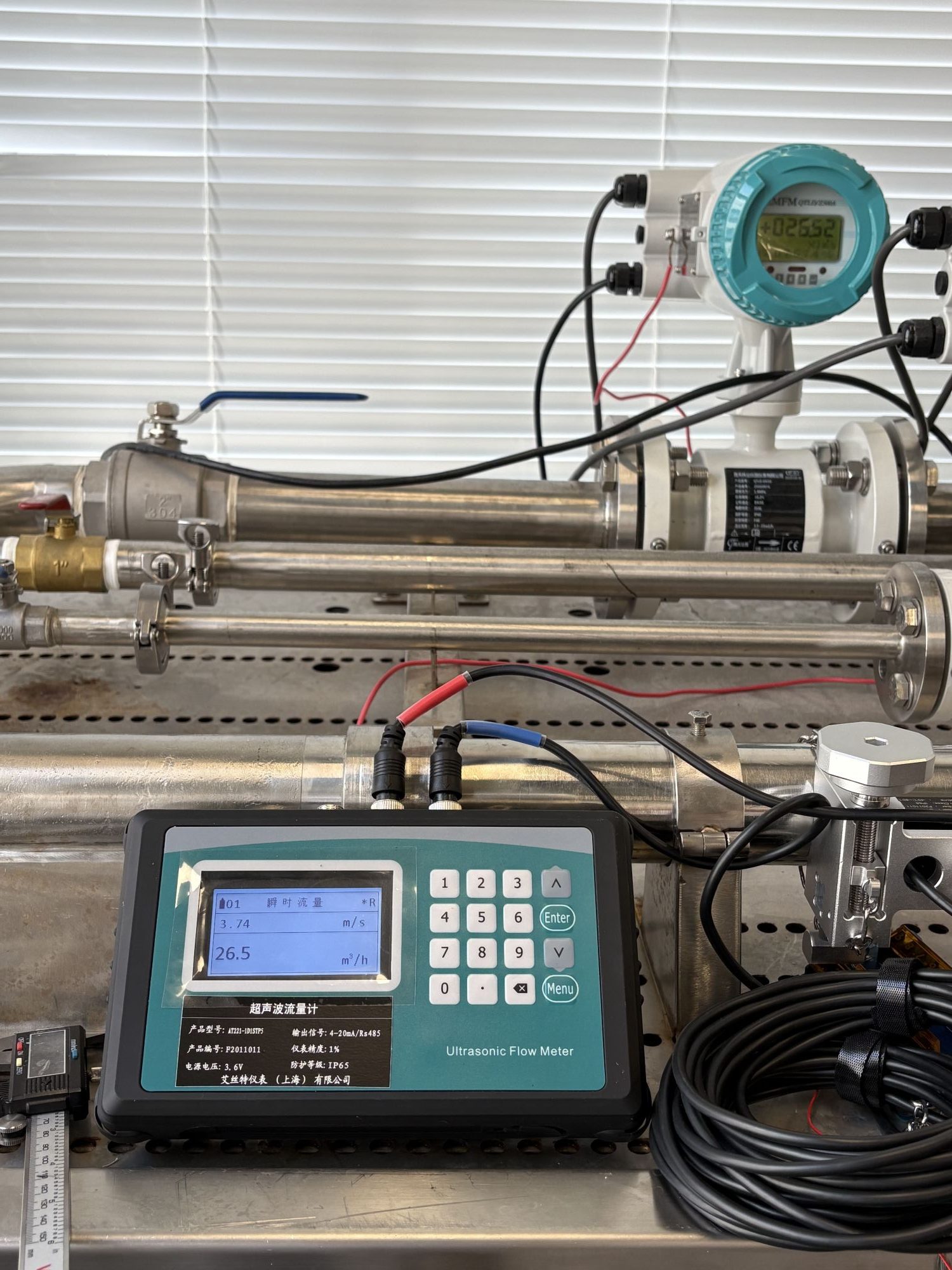

An ultrasonic flowmeter is an instrument that measures the flow of fluids by utilizing the propagation characteristics of ultrasonic waves. It does not require direct contact with the fluid being measured. By capturing the propagation information of ultrasonic waves in the fluid through an external sensor, it achieves non-invasive flow measurement. It has a wide range of applicable media, covering various liquids such as water, oil, and chemical solutions, as well as some gases, and is suitable for the needs of different industrial scenarios. Now let’s take a look at what the advantages and disadvantages of ultrasonic flowmeters are.

1. Working principle

When an ultrasonic beam propagates in a liquid, the flow of the liquid will cause a slight change in the propagation time, and the change in the propagation time is proportional to the flow rate of the liquid. At zero flow, the time required for the two sensors to emit and receive sound waves is exactly the same (the only technology that can actually measure zero flow). When a medium flows, the transmission time of sound waves in the countercurrent direction is longer than that in the downstream direction. Its relationship conforms to the following expression:

2. Advantages of ultrasonic flowmeters

① Non-contact measurement, strong adaptability: The sensor is installed outside the pipeline and does not come into direct contact with the medium. It can measure corrosive, high-viscosity, and impimpurity special media, while avoiding wear and contamination of the instrument by the medium.

② Stable measurement accuracy and low maintenance cost: With no mechanical moving parts, the probability of equipment failure is reduced. There is no need for frequent daily maintenance. Only regular calibration is required to ensure measurement accuracy, making the long-term usage cost more advantageous.

③ Easy installation and minimal impact on pipelines: There is no need to cut off pipelines or stop production. The installation process will not affect the technological flow, making it particularly suitable for the flow monitoring upgrade and transformation of pipelines that have already been put into operation.

3. Disadvantages of ultrasonic flowmeters

① Limited by the characteristics of the medium: For media containing a large amount of bubbles and suspended particles, the ultrasonic signal will be severely attenuated, resulting in distorted measurement data. When measuring gases, extremely high stability requirements are placed on the temperature and pressure of the medium.

② Strict installation environment requirements: Scale and rust on the inner walls of the pipes can affect signal transmission. When there is strong electromagnetic interference near the pipes, it can also interfere with measurement accuracy, and additional shielding measures need to be taken.

③ Weak adaptability to low-temperature conditions: In extremely low-temperature environments, the ultrasonic emission efficiency of the sensor will decline, and both the measurement range and accuracy will be affected to varying degrees.