The solution for ultrasonic flowmeters to address the imbalance of water volume in sewage treatment plants

Let’s first explore what water balance in a sewage treatment plant is: the balance of the total inflow and outflow of the sewage treatment plant. Nowadays, the issue of imbalance in the inflow and outflow of sewage treatment plants has increasingly drawn the attention of relevant regulatory authorities and various sewage operation companies. The imbalance between the influent and effluent water volumes is extremely severe, which is influenced by factors such as the sewage and sludge treatment process, the amount of reused water, the level of equipment, and the installation position of flow meters.

From the perspective of flow measurement, let’s conduct a detailed analysis of the solutions to the imbalance in the inflow and outflow of sewage treatment plants.

1. Problem understanding

In fact, apart from the influencing factors we mentioned earlier such as sewage and sludge treatment processes, reclaimed water volume, and equipment level, the imbalance between influent and effluent water volumes is also related to the installation position of the flowmeter and how it is regularly calibrated.

2. Suggestions for the installation position of the flowmeter

Install an ultrasonic flowmeter at the total inlet of the gravity flow to directly measure the data of the total inlet of the sewage treatment plant. Generally, under non-full pipe conditions, if the flow measurement error of the ultrasonic flowmeter is less than 3%, it can meet the conditions set by the relevant regulatory authorities.

A flowmeter is installed on the return pipe of the sump. The sum of the electromagnetic flowmeter and this flowmeter after the first-stage lift pump room is the total influent water volume. It should be noted that there may be multiple return pipes, and multiple sets of flowmeters need to be installed. The return pipe is usually full pipe and non-full pipe alternating, and it is necessary to consider installing an ultrasonic flowmeter.

3. Case Study

In one of the sewage treatment plants, the flow measurement potentials of the influent and effluent have asymmetric and dynamic fluctuations in the flow field, resulting in an imbalance between the influent and effluent water volumes.

Deviation verification system for comparison with reference values: -1.0% to 3.3%;

The difference between daily inflow and outflow: -2.5% to 3.7%.

After a 92-day calibration cycle, adjust the K value of the electromagnetic flowmeter, and then go through a 25-day result verification period:

The difference between the daily inflow and outflow volume has been reduced to -0.8% to 0.4%, meeting the customer’s requirements.

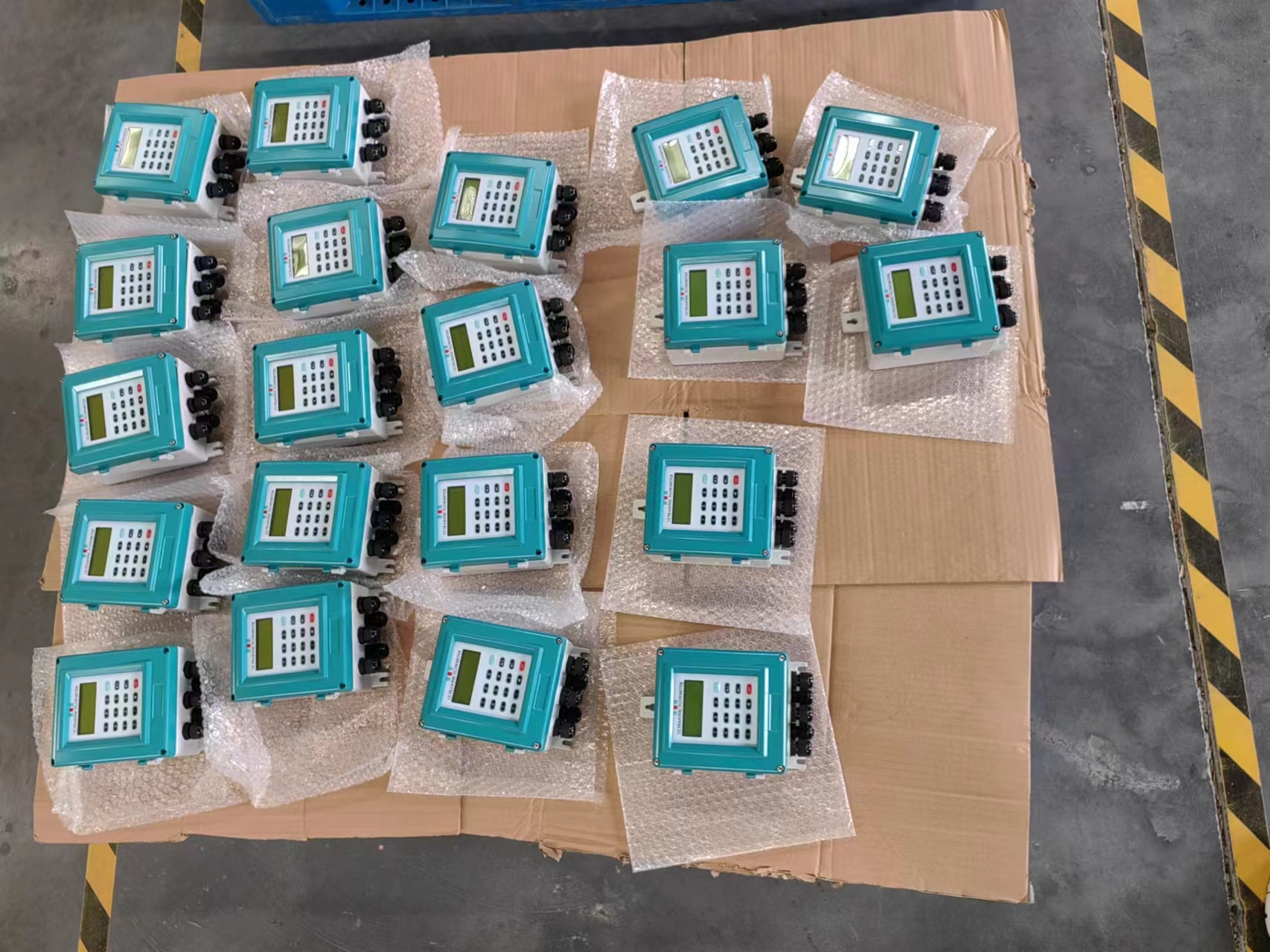

2) Aister Instruments has been established for many years and has developed the verification work of electromagnetic flowmeters, Barcol metering tanks and ultrasonic flowmeters for sewage treatment plants in many places both at home and abroad. If you have any technical questions regarding flow meters in sewage treatment plants, you can refer to our past cases, conduct comparative analysis and come up with solutions.