What are the advantages of different installation methods of sewage ultrasonic flowmeters

Today, flowmeter manufacturer Aister meters and you talk about the different advantages of different installation methods of ultrasonic flowmeters.

1, the main difference between fixed ultrasonic flowmeter and portable ultrasonic flowmeter

1) The application of different occasions, fixed ultrasonic flowmeter is used to install in a fixed position, long-term uninterrupted measurement of the flow of fluid in a specific pipeline; Portable ultrasonic flowmeters have great mobility and are mainly used for temporary measurement of fluid flow in different pipelines.

2) Different power supply methods fixed ultrasonic flowmeter requires long-term continuous operation, so to use 220V AC power supply, portable ultrasonic flowmeter can use on-site AC power supply, but also has a built-in rechargeable battery, can work continuously for 5 ~ 10h, which greatly facilitates the needs of temporary flow measurement in different occasions.

3) Some of the different functions of the fixed ultrasonic flowmeter, usually have 4-20mA signal output functions, for remote display use, but its internal storage can only store the parameters of a pipeline; Portable ultrasonic flowmeter is only to view the flow at the scene and the cumulative flow in a short period of time, so there is generally no output signal function, but in order to facilitate the measurement of different pipeline flow, it has a rich storage function, and can store the parameters of different pipelines at the same time for use at any time.

2, fixed ultrasonic flow meter and portable ultrasonic flow meter transducer power supply mode is different

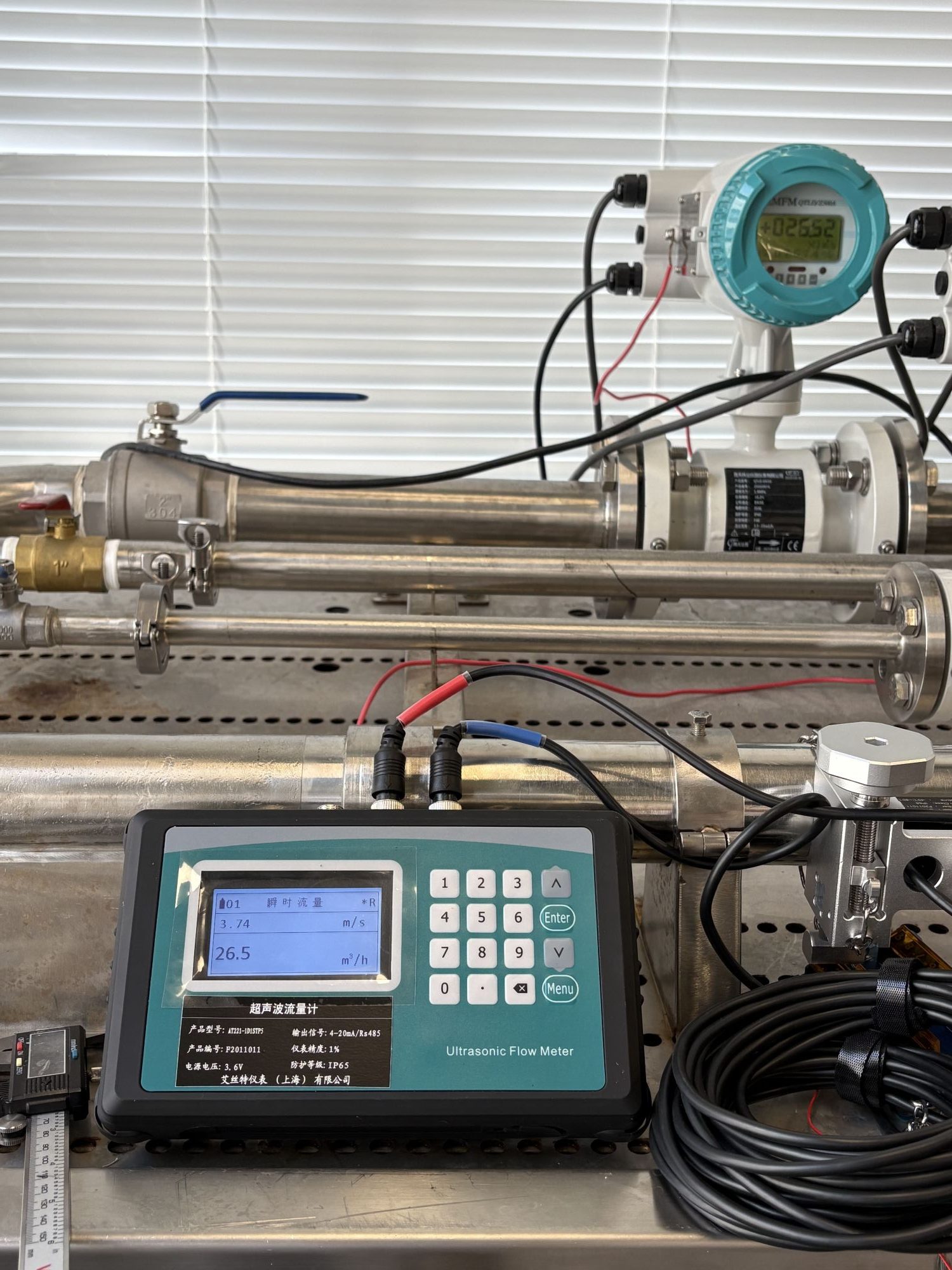

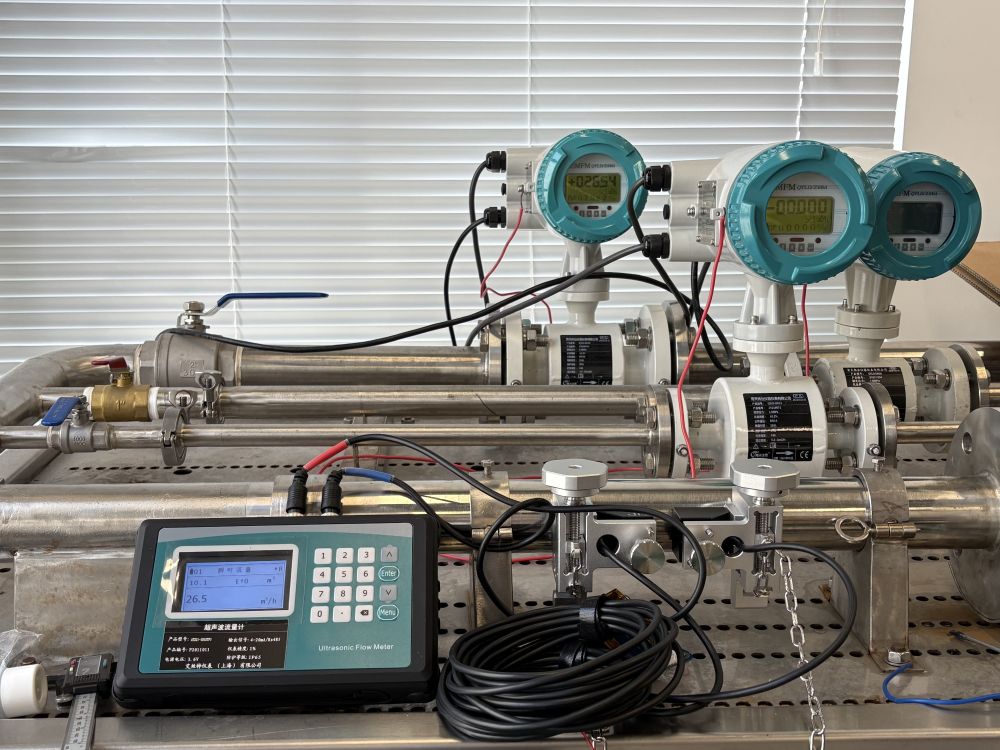

It can be divided into three kinds of ultrasonic flowmeters: external clamp type, insert type and pipe segment type.

1) The external clamp ultrasonic flowmeter is the earliest production, the user is more familiar with and widely used ultrasonic flowmeter, the installation of the transducer without pipeline break, that is, it fully reflects the ultrasonic flowmeter installation is simple, easy to use characteristics.

2) Some pipelines due to thin material, poor sound conduction, or serious corrosion, lining and pipeline space gap and other reasons, resulting in serious attenuation of ultrasonic signal, with the external ultrasonic flowmeter can not be measured normally, so the generation of pipe segment ultrasonic flowmeter. The tube segment ultrasonic flowmeter integrates the transducer and the measuring tube, which solves a difficult problem in the measurement of the external flowmeter. Moreover, the measurement accuracy is also higher than other ultrasonic flowmeters, but at the same time, it also sacrifices the advantage of the external attached ultrasonic flowmeter that the flow is not interrupted, requiring the installation of the transducer by cutting the pipeline.

3) Plug-in plug-in ultrasonic flowmeters are in the middle of the above two. The flow can not be interrupted on the installation, the use of special tools to punch holes in the pipeline with water, and insert the transducer into the pipeline to complete the installation. Because the transducer is in the pipeline, the transmission and acceptance of its signal only passes through the measured medium, but not through the tube wall and lining, so its measurement is not limited by the tube quality and tube lining material.