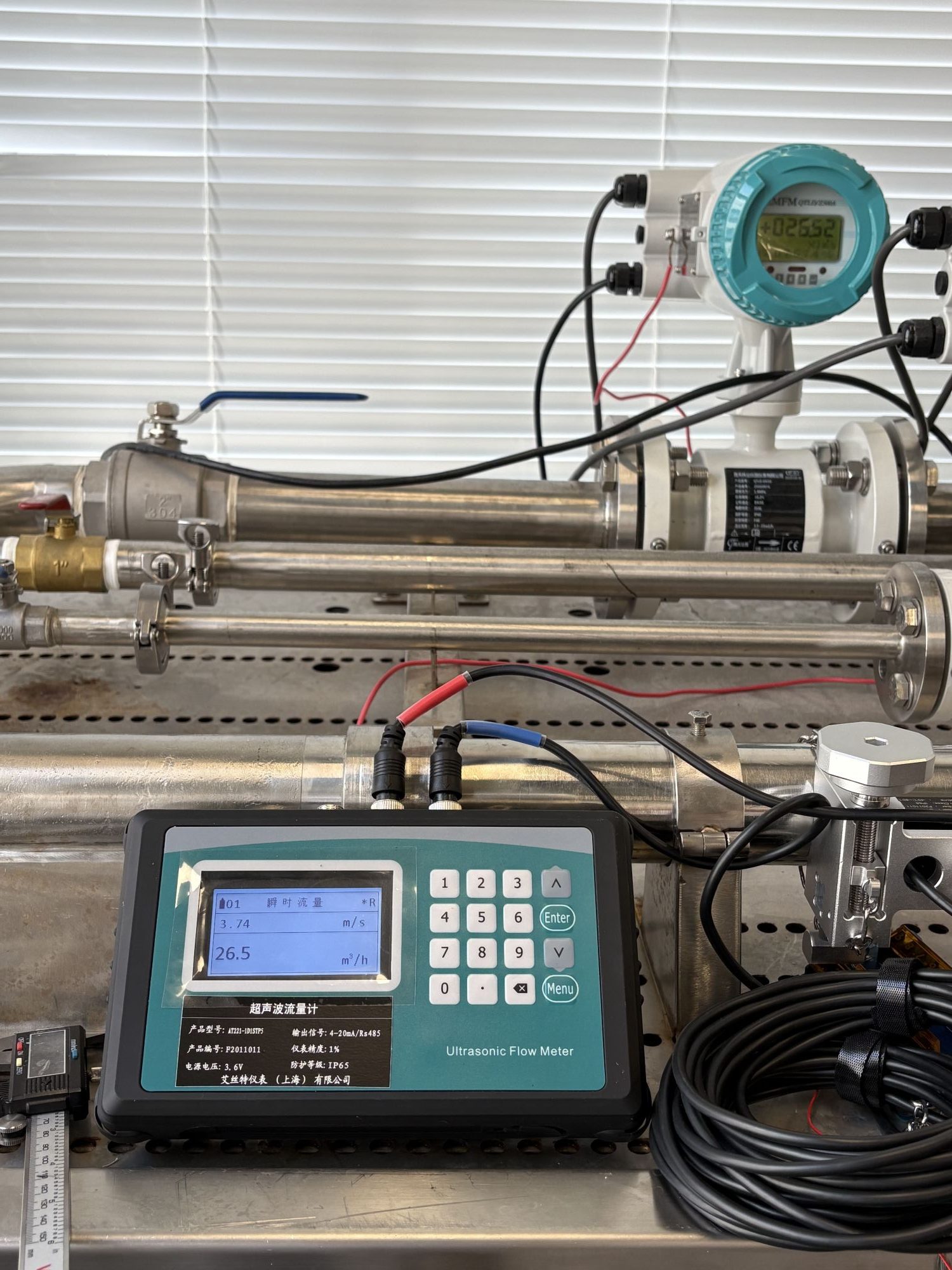

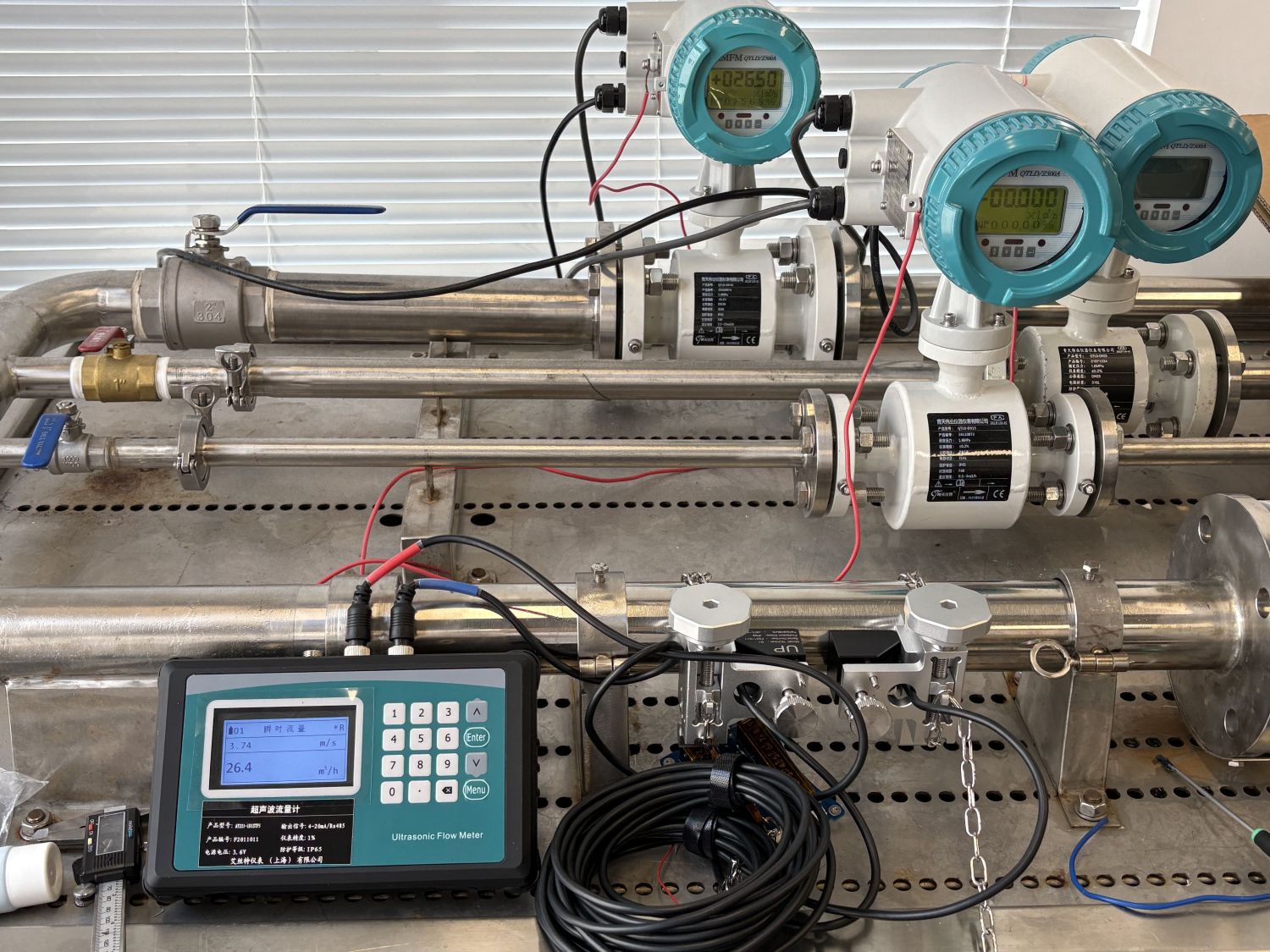

Is the signal of the external clamp-on ultrasonic flowmeter too weak during use? How to solve it easily

The external clamp-on ultrasonic flowmeter is a flow meter that is highly suitable for full pipe measurement in pipelines. It features easy installation, non-contact operation, and can measure the flow of large-diameter media as well as media that are difficult to contact and observe. Its measurement accuracy is very high and is almost unaffected by various parameters of the measured medium. It can especially solve the flow measurement problems of highly corrosive, non-conductive, radioactive and flammable and explosive media that other instruments cannot handle.

Due to its various features that other types of instruments do not have, it has now been widely used in the measurement of various liquids such as tap water, sewage and seawater in industry, and is also applied in fields such as petroleum, chemical engineering and metallurgy.

After installation, the external clamp-on ultrasonic flowmeter can generally operate normally for a long time without maintenance. If there are problems such as no signal reception or weak signal, there is no need to be surprised. As long as you follow the following steps suggested by Aister Instrument, operate in a standardized manner and handle it carefully, it will soon return to normal

First, confirm whether the flowmeter in the pipeline is filled with fluid;

2. If the pipe is too close to the wall, the probe can be installed on the pipe diameter with an inclined Angle instead of on the horizontal pipe diameter. The Z-method should be used to install the probe.

3. Carefully select the dense parts of the pipe and thoroughly polish them until smooth. Apply sufficient coupling agent and install the probe properly.

4. Carefully and slowly move each probe near the installation point to find the larger signal point, preventing the ultrasonic beam from being reflected out of the expected area due to scaling on the inner wall of the pipe or local deformation of the pipe, thus avoiding missing the installation point that can receive the stronger signal.

5. For metal pipes with severe scaling on the inner wall, the method of striking can be used to make the scaling part fall off or crack. However, it should be noted that this method sometimes does not help the transmission of ultrasonic waves at all due to the gap created between the scaling and the inner wall.

Since the external clamp-on ultrasonic flowmeter is often used to measure dirty fluids, after running for a period of time, adhesion layers often accumulate on the inner wall of the sensor, causing malfunctions. It is recommended that, where conditions permit, a large filtering device be installed upstream. This will better enhance the stable and accurate performance of the instrument and maintain the stability of the measurement data.