Several reasons why the signal of the external clamp-type ultrasonic flowmeter is too weak

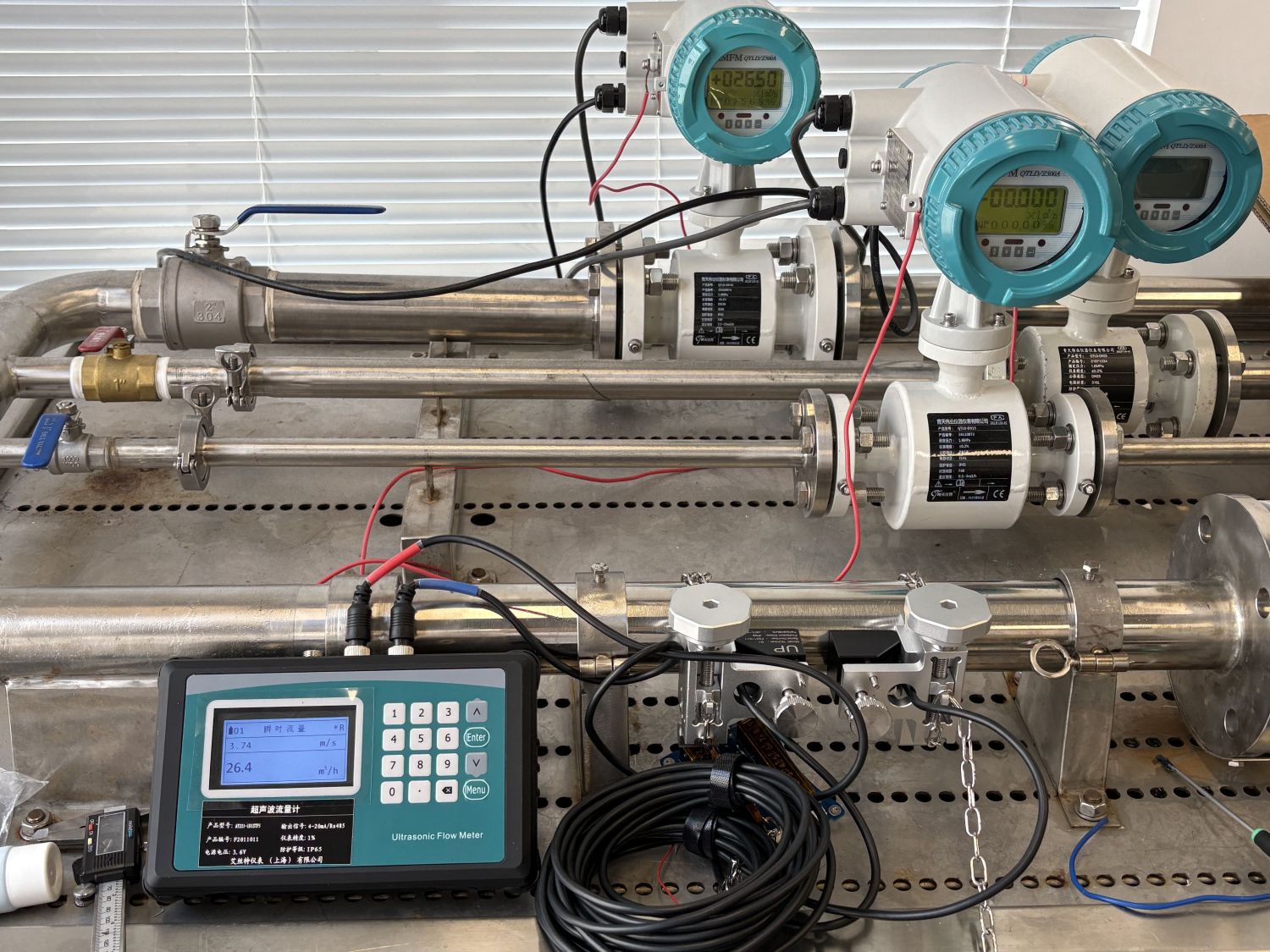

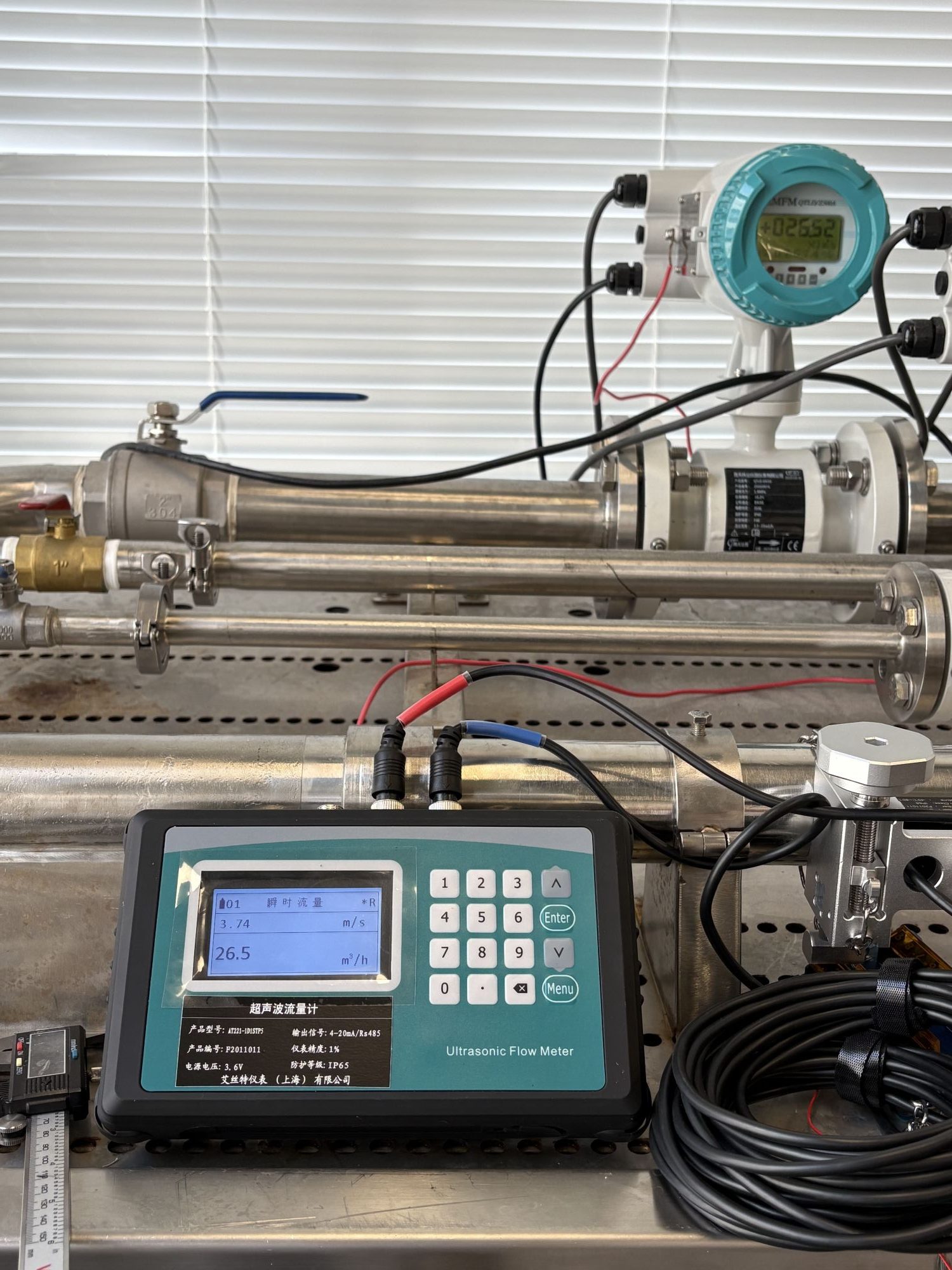

External clamp ultrasonic flowmeter is a very suitable for pipe full pipe measurement flow meter, with easy installation, non-contact type, can measure the medium flow of large pipe diameter can also be used for measuring the medium that is not easy to contact and observe.

The external clamp-type ultrasonic flowmeter can generally operate normally for a long time after installation without maintenance, if there is no signal received or the signal is too weak, as long as you refer to the following 5 recommendations of the flowmeter manufacturer Aister instrument, the standardized operation and careful treatment will quickly return to normal:

1, first confirm whether the flow meter in the pipeline is full of fluid;

2, if the pipe is too close to the wall, the probe can be installed on the diameter of the pipe with a tilt Angle, rather than on the horizontal pipe diameter, the Z method should be used to install the probe;

3, carefully select the dense part of the pipeline and fully polish bright, apply sufficient lotus mixture to install the probe;

4. Carefully move each probe slowly near the installation point to find a larger signal point to prevent the installation point that can receive a stronger signal from being missed due to scaling on the inner wall of the pipeline or due to local deformation of the pipeline that causes the ultrasonic beam to reflect the expected area;

5, the inner wall of the metal pipe serious scaling can be used to make the scaling part fall off or crack, but it should be noted that this method sometimes because of the gap between the scaling and the inner wall and does not help the transmission of ultrasonic.

Because the external clamped ultrasonic flowmeter is commonly used to measure dirty fluid, after running for a period of time, it often accumulates adhesive layer on the inner wall of the sensor and causes failure. It is recommended that the filter device can be installed upstream if there are conditions, which will better play the stability of the instrument and maintain the stability of the measurement data.