The initial installation of commonly used ultrasonic flowmeters must follow the following points

For industrial and mining enterprises with relatively old pipelines, it is advisable not to use the 2-layer acoustic layer (V method) for sensor installation. Instead, the 1-layer acoustic layer (Z method) should be selected. This installation method makes the ultrasonic waves emitted by the flow sensor of the ultrasonic flowmeter easily received by the measured flow sensor, ensuring the signal strength of the ultrasonic flowmeter’s main unit and guaranteeing high-precision measurement values.

2. When measuring new pipes, if there are painted or zinc-coated pipes, the surface of the pipe can be treated with coarse yarn first, and then continued with fine yarn. This ensures that the installation point of the flow sensor of the ultrasonic flowmeter is smooth and flat, and the flow probe of the ultrasonic flowmeter can make good contact with the outer wall of the measured pipe.

3. When the pipe is running vertically upward, if the fluid inside the pipe flows from bottom to top, it can be measured. However, if the liquid flows from top to bottom, this pipe is not suitable for flow data collection.

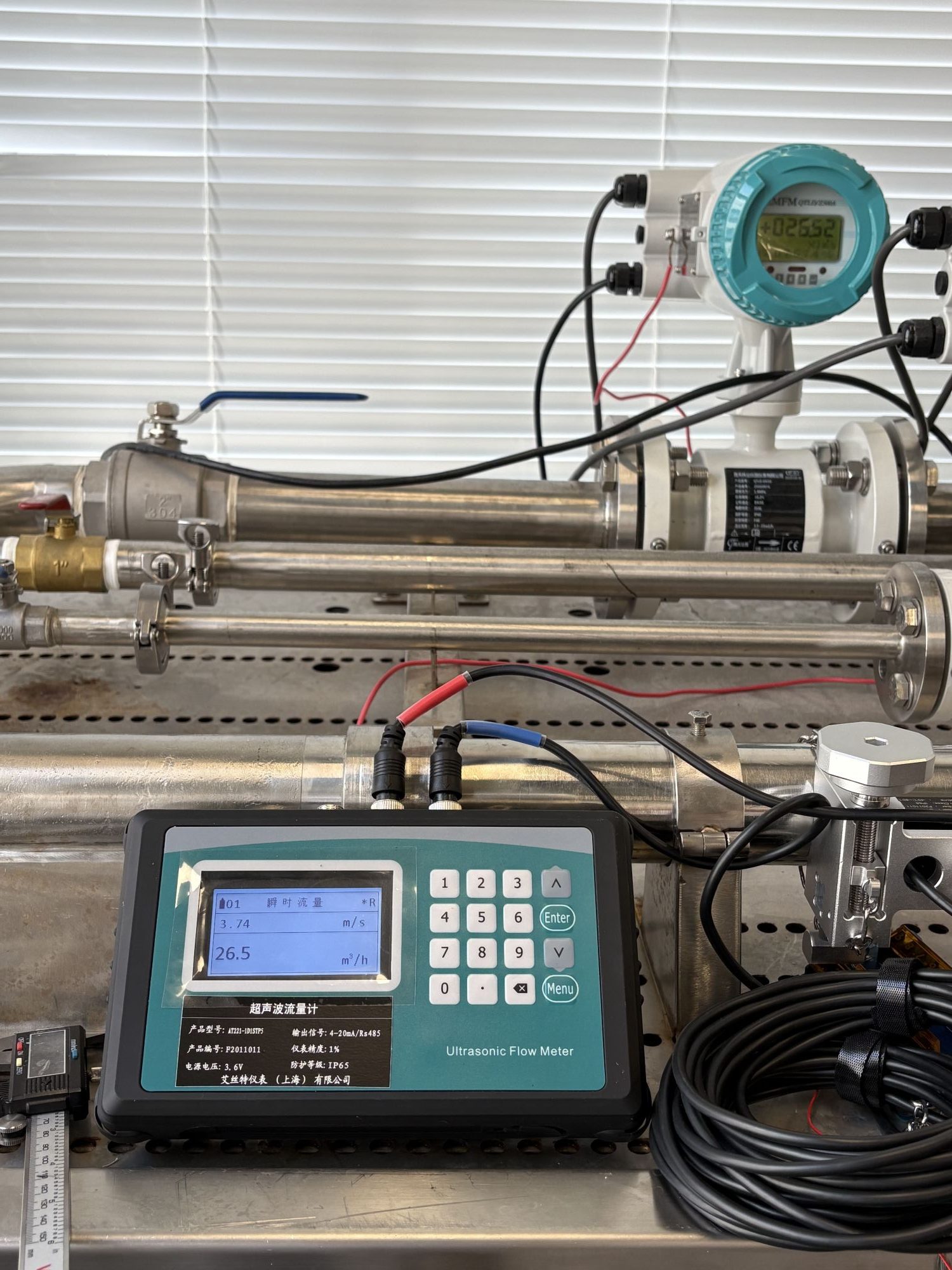

4. Additionally, before collecting flow data on a certain pipeline, it is essential to measure the outer circumference of the pipeline (using a tape measure), wall thickness (using a thickness gauge), and the temperature of the outer wall of the pipeline (using a surface temperature measuring instrument) by yourself.

5. Remove the insulation layer and protective layer within the installation section, and grind the wall surface where the transducer is installed clean. Avoid local depressions, smooth out protrusions, and grind off the paint and rust layers.

6. For vertically set pipelines, if it is a single-channel propagation time method instrument, the installation position of the sensor should be as close as possible to the bending axis plane of the upstream elbow pipe to obtain the average value that is relatively close after the distortion of the elbow pipe flow field.

7. The sensor installation area of the ultrasonic flowmeter and the reflection area of the pipe wall must avoid interfaces and welds.

8. The lining and scale layer of the pipe at the sensor installation site of the ultrasonic flowmeter should not be too thick. There should be no gap between the lining, the rust layer and the pipe wall. For severely rusted pipes, a hand hammer can be used to strike the pipe wall to shake off the rust layer on the wall and ensure the normal transmission of sound waves. But it is necessary to be careful not to hit a dent.

9. There should be sufficient coupling agent between the working surface of the sensor and the pipe wall, and no air or solid particles should be present to ensure good coupling.