Ultrasonic flowmeter Guide

Ultrasonic flowmeter Guide

The working principle of ultrasonic flowmeters

According to the principle of signal detection, ultrasonic flowmeters can be classified into methods such as the propagation speed difference method (direct time difference method, time difference method, phase difference method and frequency difference method), beam deflection method, Doppler method, cross-correlation method, spatial filtering method and noise method, etc.

Time difference method: Calculate the speed of the fluid being measured by measuring the time difference caused by the different propagation speeds during forward and backward propagation.

It adopts two acoustic wave transmitters (SA and SB) and two acoustic wave receivers

(RA and RB). Two sets of sound waves from the same source are transmitted respectively between SA and RA and between SB and RB. They are installed along the pipeline at an Angle of θ (generally θ=45°) to the pipeline (as shown in Figure 1). Because the sound waves transmitted downstream are accelerated by the fluid while those transmitted upstream are delayed, the time difference between them is proportional to the flow velocity. The flow velocity can also be measured by sending a sinusoidal signal to measure the phase shift between two groups of sound waves or by sending a frequency signal to measure the frequency difference.

2. Phase difference method: Calculate the speed of the phase difference caused by the time difference during forward and reverse propagation.

Its transmitter sends a beam of sound waves along an axis perpendicular to the pipe. Due to the effect of fluid flow, the sound beam is deflected downstream by a certain distance. The offset distance is proportional to the flow velocity.

3. Frequency difference method: Measure the frequency difference of the sound ring during forward and reverse propagation.

q

How does an ultrasonic flowmeter work?

Ultrasonic flowmeters are a non-contact method for measuring flow velocity. The clamping device fixed on the outside of the pipe can measure corrosive liquids without damaging the sensor.

These two types of ultrasonic flowmeters, the time-difference type, function respectively through two different technical methods. Doppler ultrasonic flowmeters must have particles or foam to reflect ultrasonic signals. To consider the lower limit of the concentration and size of the solid or foam, the liquid must be able to flow at a sufficient speed to maintain the suspension of the solid.

When transmitted to a pipe containing such discontinuous flowing liquid, ultrasonic pulses or beams will reflect, and the change in frequency is proportional to the flow rate of the liquid. Therefore, ultrasonic flowmeters calculate the flow rate based on the velocity at the discontinuous points rather than the velocity of the liquid.

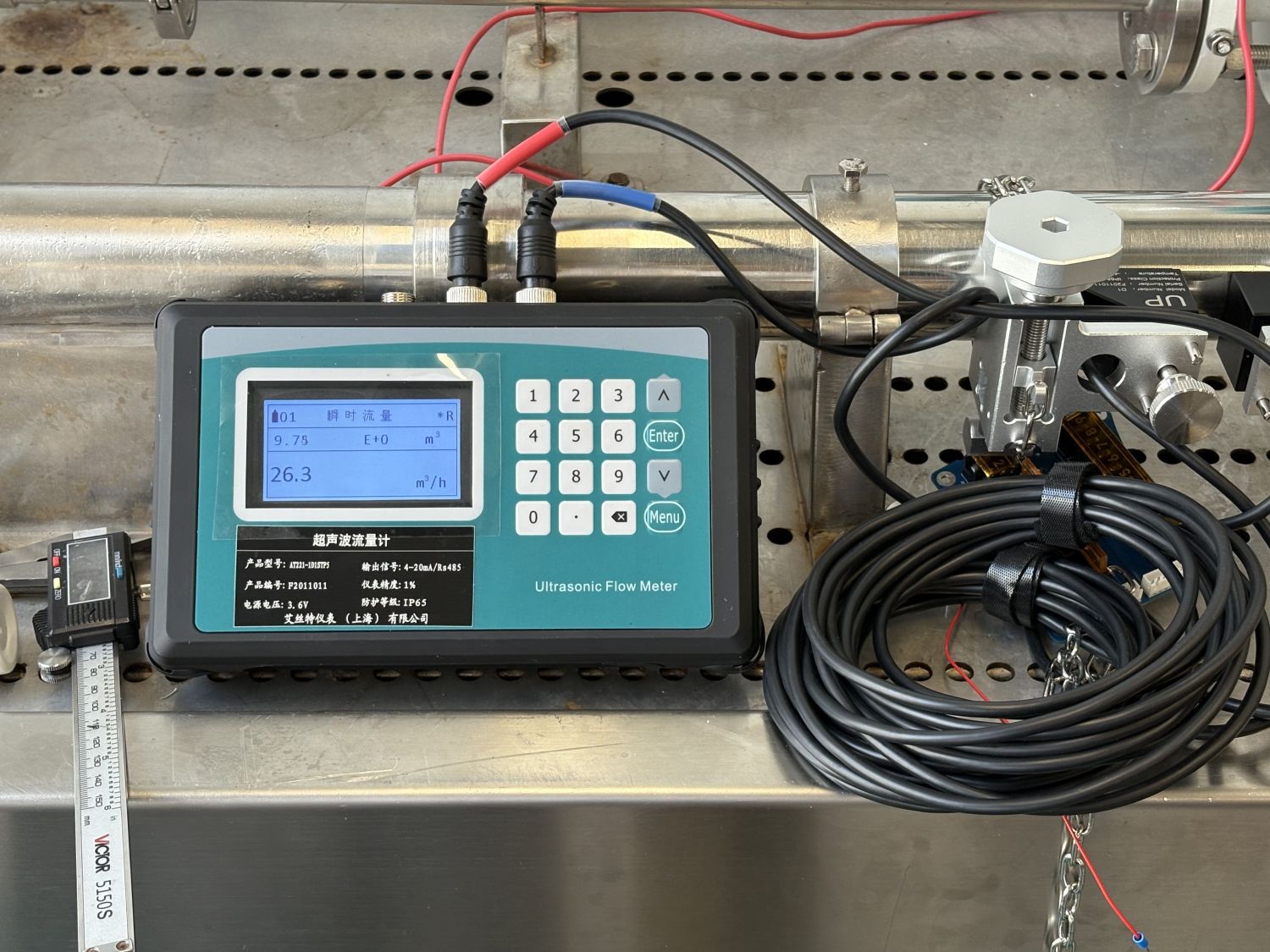

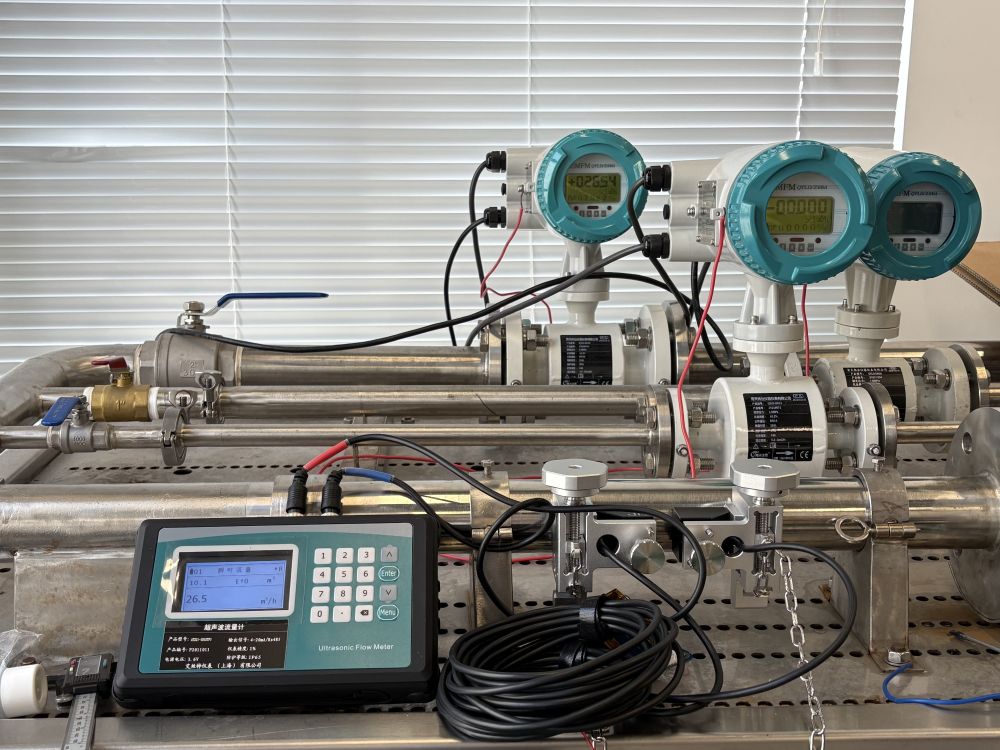

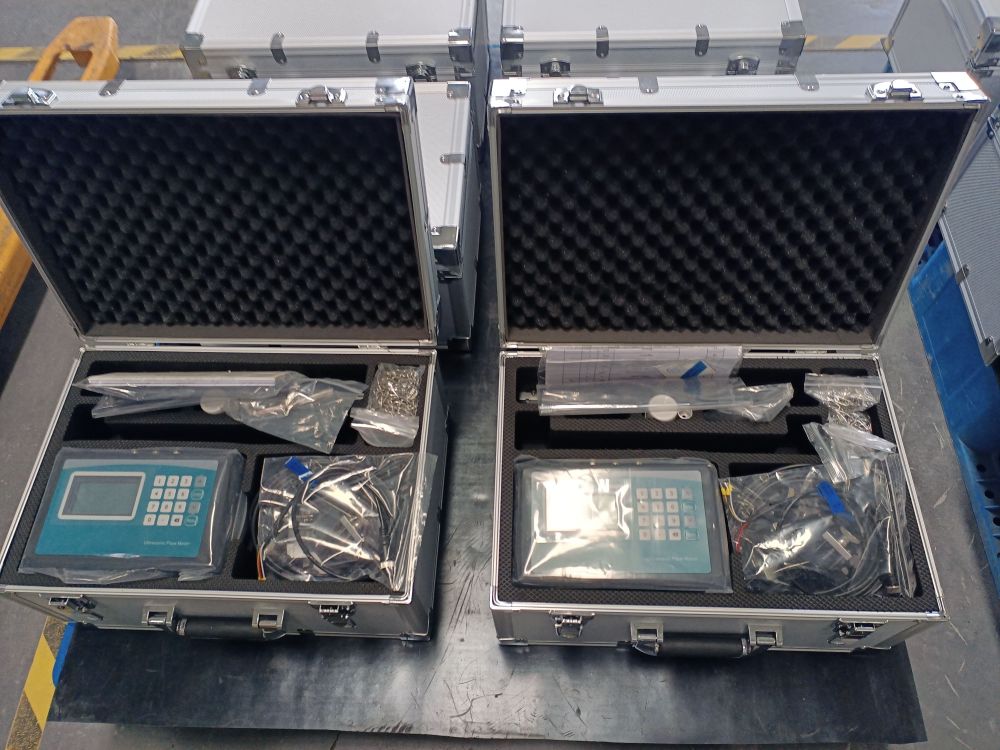

The structure and composition of ultrasonic flowmeters

The flowmeter mainly consists of the flowmeter body, ultrasonic transducers and their installation components, signal processing units and flow computers. For contact and clamp-on flowmeters, the on-site pipeline where the transducer is installed can be used as a pipe section.

The transducer of a contact flowmeter is in direct contact with the fluid being measured, while the transducer of an external clamp flowmeter is tightly installed on the outer wall of the pipeline.

The ultrasonic flowmeter is mainly composed of several major parts, including the ultrasonic generator, ultrasonic receiver, electronic circuit, flow display and accumulation system. Among them, the ultrasonic generator is mainly used to generate ultrasonic waves and emit them into the fluid; The ultrasonic receiver is mainly used to receive ultrasonic waves after passing through the fluid. After being received, ultrasonic waves are amplified, converted and processed by electronic circuits, and then the flow rate is transmitted to the display screen in the form of electrical signals, and the results are displayed. The cumulative system completes the cumulative calculation of the flow.

Maintenance and care of ultrasonic flowmeters

1. Cleaning and maintenance

(a) Regularly check whether the sensors and pipelines are clogged with impurities, dirt or other issues, and clean them. Use a soft cloth or brush to remove the adhering substances. Avoid using chemical solvents to prevent damage to the sensor.

(b) Check whether the sensor is firmly fixed. If it is loose, tighten the screws in time.

(c) Clean the display screen and buttons to prevent dust, oil stains and other substances from affecting operation and observation.

2. Regular calibration

(a) According to the manufacturer’s recommendation, regular calibration operations should be carried out to ensure the accuracy of the flowmeter. Under normal circumstances, calibration can be carried out through the built-in calibration function of the system or by professional technicians.

(b) Temperature calibration: Some ultrasonic flowmeters require temperature calibration to ensure accurate temperature measurement.

3. Inspection and Maintenance

(a) Regularly check whether the ultrasonic sensor is intact and undamaged, especially the sensing panel and probe.

(b) Check whether the cable connection is good and eliminate measurement errors caused by connection problems.

(c) If any malfunction or abnormality is found, contact the supplier or maintenance personnel in a timely manner for repair or replacement of parts.

4. Maintain a suitable working environment

(a) Avoid exposure to extreme temperatures, humidity or corrosive gases, etc., to prevent affecting the performance and lifespan of the flowmeter.

(b) Avoid physical shock and vibration to prevent damage to mechanical components.

(c) Regularly inspect the power supply and grounding system to ensure stable power supply and good grounding.

Precautions for ultrasonic flowmeters

1. Consider fluid characteristics:

(a) When installing an ultrasonic flowmeter, the properties of the fluid need to be taken into account, such as parameters like temperature, pressure, and viscosity. Ensure that the selected flowmeter can adapt to the characteristics of the fluid and meet the measurement requirements.

(b) For special fluids, such as corrosive liquids or high-temperature and high-pressure fluids, it is necessary to select flowmeters compatible with them and take corresponding protective measures.

2. Pay great attention to safety precautions:

(a) During the installation process, please strictly follow the safety operation procedures and wear appropriate personal protective equipment. Ensure the safety of the working area and prevent the occurrence of accidents.

(b) If operations such as cutting or welding of the pipes are required, they should be carried out by experienced professionals. Avoid damaging pipelines and equipment, and ensure the integrity of the pipelines after construction.

3. Conduct thorough testing

(a) After installation is completed, conduct a comprehensive test to ensure that the measurement results of the ultrasonic flowmeter are consistent with the actual flow rate, without error or deviation.

During the testing process, focus on checking whether the connection between the sensor and the pipeline is tight, whether the cable connection is normal, and conduct tests under various flow conditions to verify the accuracy and stability of the flowmeter.

The maintenance and upkeep of ultrasonic flowmeters are the keys to ensuring their reliability and stability. In addition to cleaning, maintenance, calibration and inspection and repair, aspects such as software and firmware updates, fault monitoring and alerts should also be taken into consideration. When installing, in addition to choosing the appropriate position and correctly installing the sensor, it is also necessary to consider the fluid characteristics, follow the safety operation procedures, and conduct thorough tests. Regular maintenance and following installation precautions can ensure the stable operation of ultrasonic flowmeters and obtain accurate and reliable flow measurement results.

Installation matters of ultrasonic flowmeters

Installation location selection

(a) Select an appropriate installation position according to the measurement requirements. Avoid factors that may affect measurement accuracy, such as locations with low liquid flow rates, near strong vibration sources, and at pipe bends.

(b) Ensure that the installation location is convenient for maintenance and upkeep, and enables easy operation and inspection of the sensor and other components.

Correct installation of the sensor

(a) Follow the installation guidelines provided by the manufacturer to ensure the correct installation direction and distance requirements of the sensor.

(b) Before installation, clean the interior of the pipeline to ensure that there are no impurities or deposits that could affect the accuracy of the measurement.

(c) Use appropriate sealing materials and fasteners to ensure the sealing and firmness of the interface between the sensor and the pipe.

Cable wiring and connection

(a) Use cables that meet the requirements for wiring to prevent interference and signal loss.

(b) Keep the cable at a distance from other electrical equipment, high-voltage lines, etc., to avoid mutual interference.

(c) Ensure that the cable connection is firm and reliable to avoid measurement errors caused by loose cable connections.

Verification and debugging

(a) Conduct preliminary verification and commissioning after installation, check whether the measurement results are normal, and eliminate possible problems.

(b) According to the operation manual provided by the manufacturer, set the corresponding parameters and configure the system to ensure the normal operation of the flowmeter.