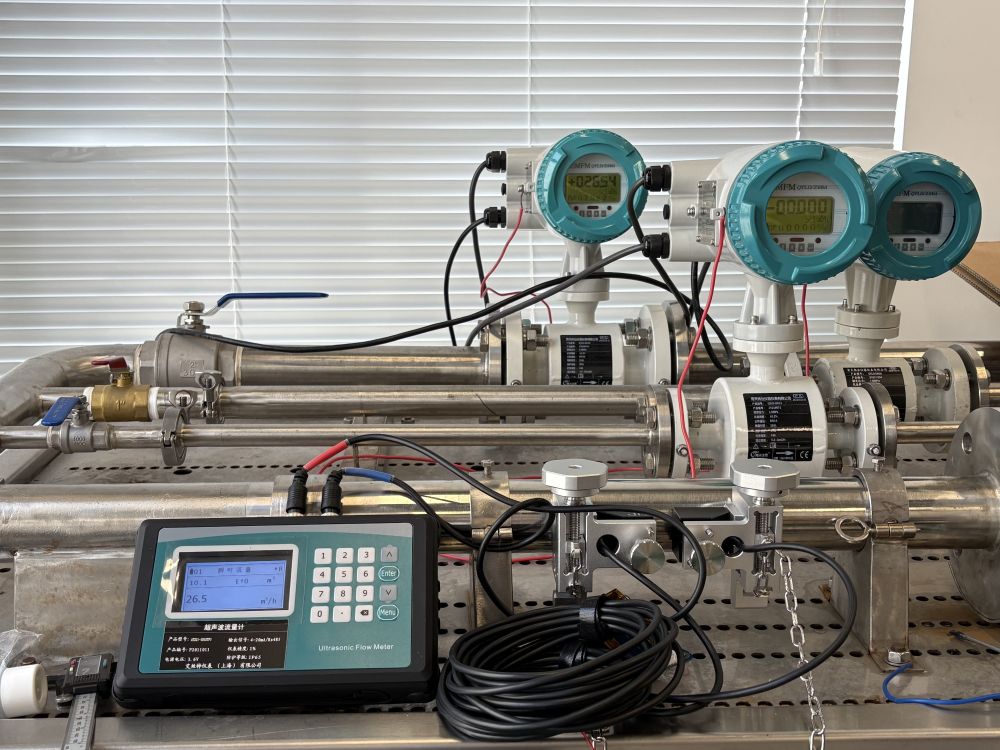

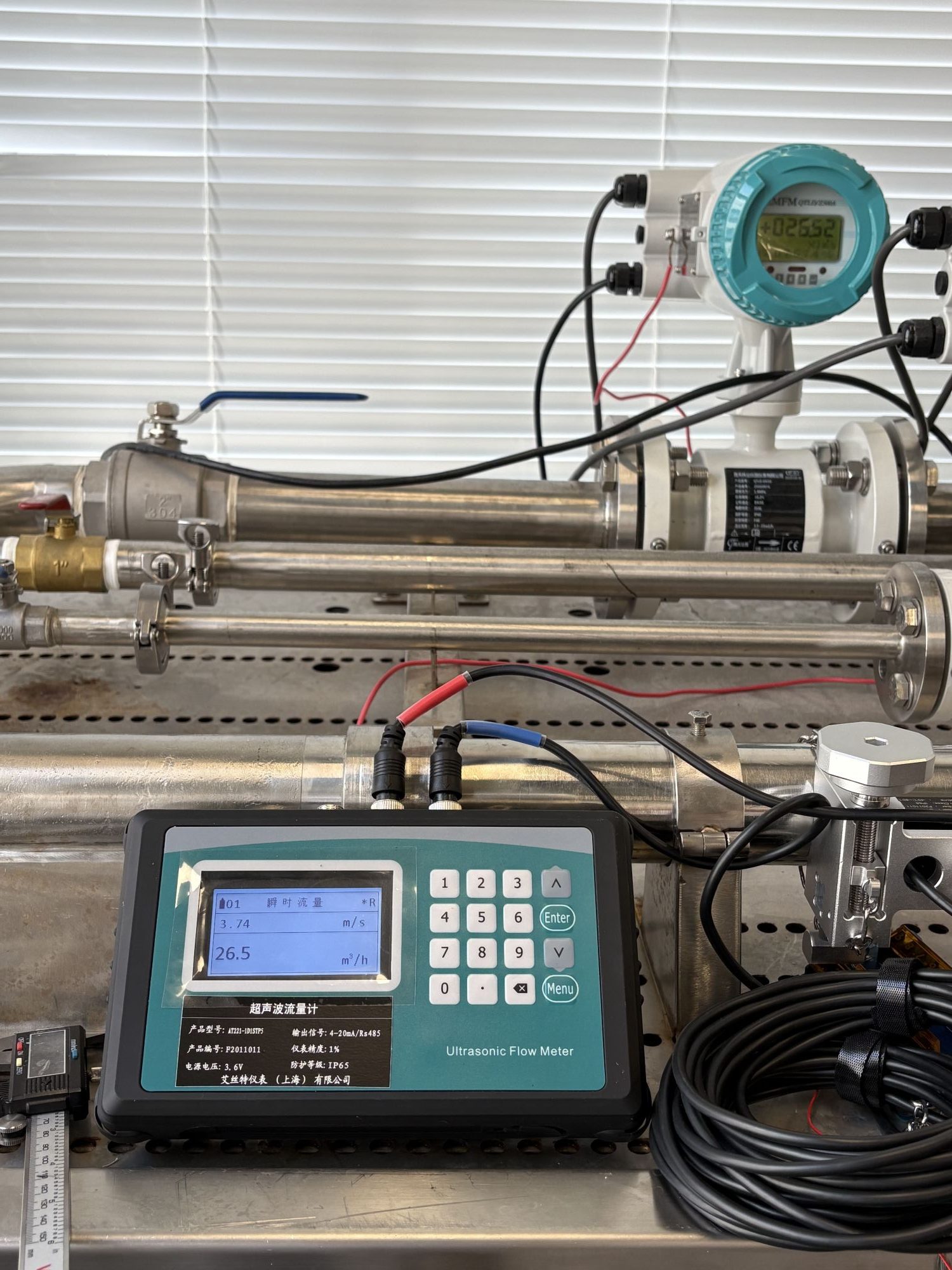

The installation points of the external clamp ultrasonic flowmeter

Ultrasonic flowmeter has the advantage of its working principle. In the large pipeline water flow measurement has a large proportion, today the ultrasonic flowmeter manufacturer Aister for the installation method and main points of the external clamp ultrasonic flowmeter for you to make the following explanation.

1. The sensor (that is, 2 probes) of the external clamped ultrasonic flowmeter has 2 installation methods under the normal premise, which are V method installation and Z method installation.

The Z method is recommended for DN200mm-6000mm pipelines, and the Z method can also be recommended when the V method fails to detect the signal or the signal quality is poor. When installing, the vertical distance between the two sensors along the direction of the tube axis is equal to the installation distance, and ensure that the two sensors are on the same axis, and pay attention to the transmission direction must be relative (the direction of the two sensors is in). Because the Z method is the ultrasonic wave directly transmitted in the medium, the signal is not reflected, so the signal intensity attenuation is minimal. Therefore, Z method has the characteristics of high signal strength and reliable operation.

The V method is recommended for DN15mm-200mm pipelines. When installing the two sensors, align them horizontally, and the center line is parallel to the pipeline axis. Note that the emission direction must be relative (the direction of the two sensors is inward). V method has the characteristics of easy to use and accurate measurement. For pipelines with diameter less than DN50mm, the installation accuracy is higher, please pay attention to the parameters of signal strength, signal quality, and transmission time ratio.

2. Enter the measurement parameters to obtain the installation distance

Before starting the measurement, it is necessary to perform the initial setting of the flow meter, set the sensor installation distance, which refers to the innermost edge distance of the two sensors, and install the sensor according to this data.

3. Handle the installation point

There are two mounting points for the external clamp sensor, which are divided into upstream sensor and downstream sensor. When processing the two installation points, the processing area of one installation point and the size of the probe are almost on the line, and the processing area of the other installation point should be 2 or 3 times the size of the probe (with the installation point as the center) to facilitate debugging signals. First, clean the area outside the tube where the sensor is to be installed to remove rust and paint. If there is an anti-rust layer should also be removed, with a sander to polish out the metallic luster, and then wipe off the oil and dust with a clean rag.