Several key elements that need to be known before applying ultrasonic flowmeters

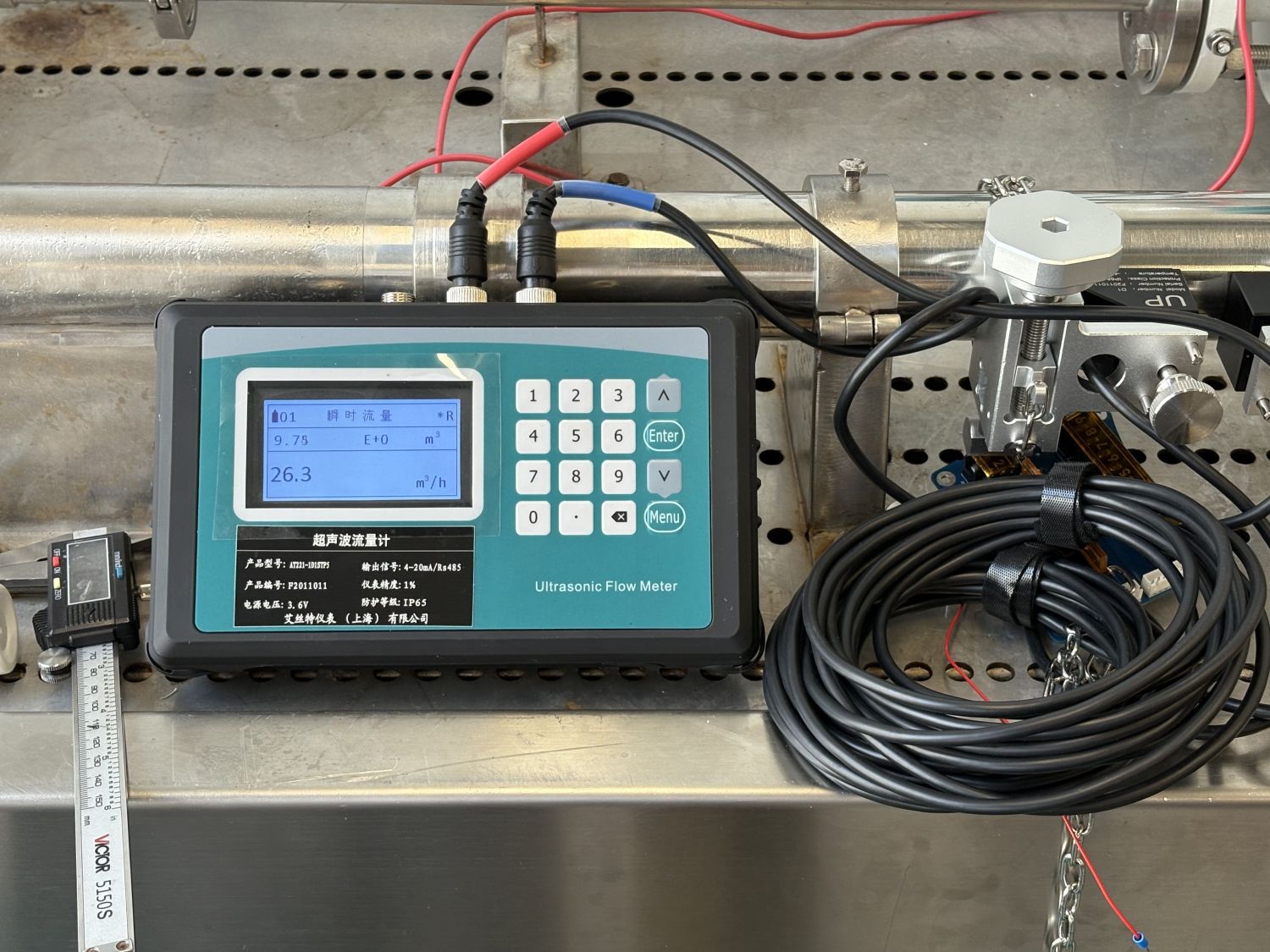

The accuracy of ultrasonic flowmeters in measuring fluid flow is closely related to the on-site working conditions. When selecting the position of the probe equipment, the following conditions should be met:

1) There is not much dust in the workplace.

2) Straight pipe section length: more than 10D on the upstream side and more than 5D on the downstream side;

3) There must be no disturbing elements (such as pumps, valves, etc.) within 30 days on the upstream side.

4) The fluid must cover the entire pipe and must not contain bubbles or excessive impurities.

5) The pipeline of the equipment probe should not have severe mechanical oscillation.

6) The space around the pipeline of the equipment probe should meet the requirements.

2. The precise values of relevant quantities such as the material of the inspected pipeline, the outer diameter of the pipe, the wall thickness of the pipe, the material and thickness of the inner pipe fabric, the medium inside the pipe, and the medium temperature, etc., shall be measured and verified on the inspection site to ensure the measurement accuracy.

3. Common flow points in on-site working conditions, so as to verify the common flow points of users and improve the accuracy of online detection.

4. Online verification of operations

This is a job with strong technical and experiential requirements, so the inspectors need to be strictly trained. In particular, it is required that the operators should carry out online inspection work with a scientific mindset. In the actual usage process, we have found that the inaccurate measurement of ultrasonic flowmeters is mostly caused by improper probe equipment. Therefore, correctly installing the probe becomes a key issue. We believe that the following principles should be followed during the process of installing the probe.

1) Regarding horizontal pipelines, the probe should be installed within ±45° of the horizontal centerline.

2) The probe should be avoided to be installed at the deformed parts of the pipeline, flanges or welding areas.

3) Before the equipment is installed, the surface of the probe equipment should be treated. Firstly, rust, dust and other contaminants on the pipe surface should be removed (if there is a protective layer on the pipe surface, it should be peeled off first) to make the pipe wall surface smooth and free of dirt.