How to choose a flowmeter for domestic sewage?

In the flow measurement of domestic sewage, choosing the appropriate flowmeter is of vital importance to ensure the accuracy and reliability of the measurement results. Here are some suggestions to help you choose a flowmeter suitable for domestic sewage:

1. Consider the characteristics of the sewage

Composition and properties: Domestic sewage usually contains suspended solids, organic matter and other impurities, but its corrosiveness is relatively weak. Meanwhile, domestic sewage has a certain degree of conductivity, which is an important consideration when choosing an electromagnetic flowmeter.

Flow range: Based on the scale and processing capacity of the treatment plant, determine the required measured maximum, minimum and normal flow range.

2. Selection of flowmeter type

Electromagnetic flowmeter

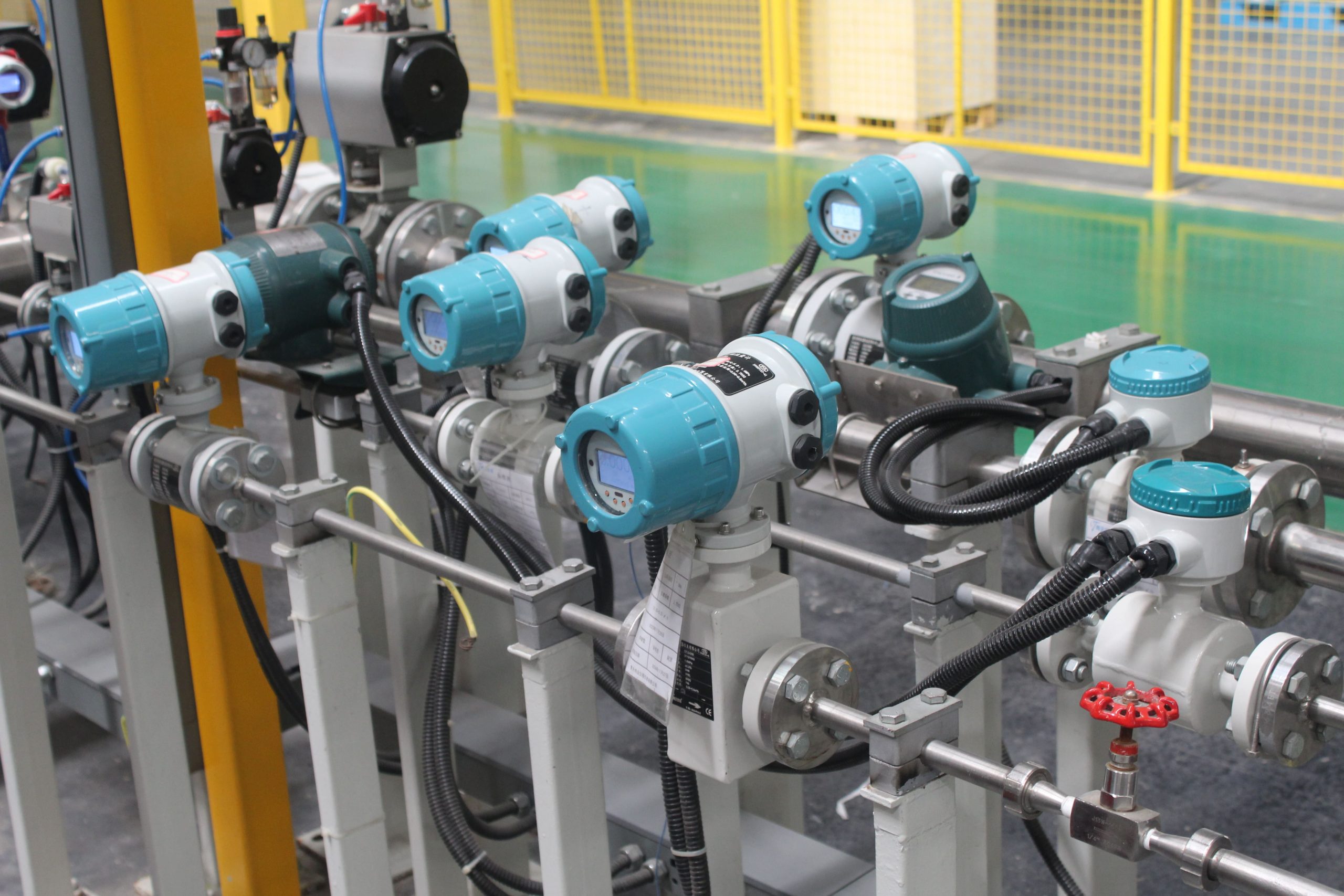

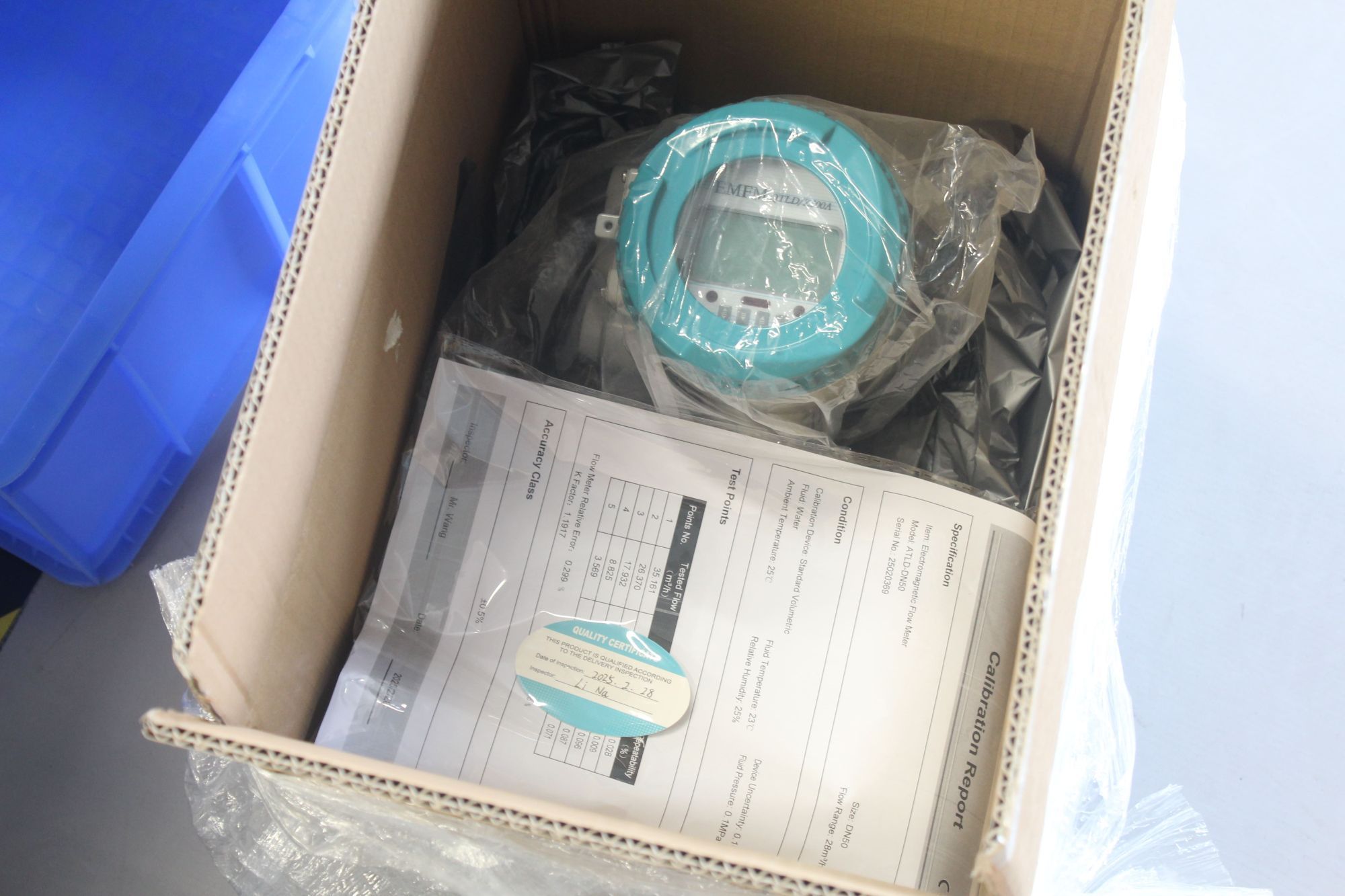

Advantages: The electromagnetic flowmeter operates based on Faraday’s law of electromagnetic induction and is suitable for measuring the volume flow of conductive liquids. It is not affected by fluid temperature, pressure, density and viscosity, and has high measurement accuracy. For domestic sewage, a medium with certain conductivity, electromagnetic flowmeters are a very good choice.

Key points for selection:

Inner lining material: Select the appropriate inner lining material based on the abrasiveness and corrosiveness of the sewage. For instance, rubber inner lining is suitable for domestic sewage with a high content of impurities.

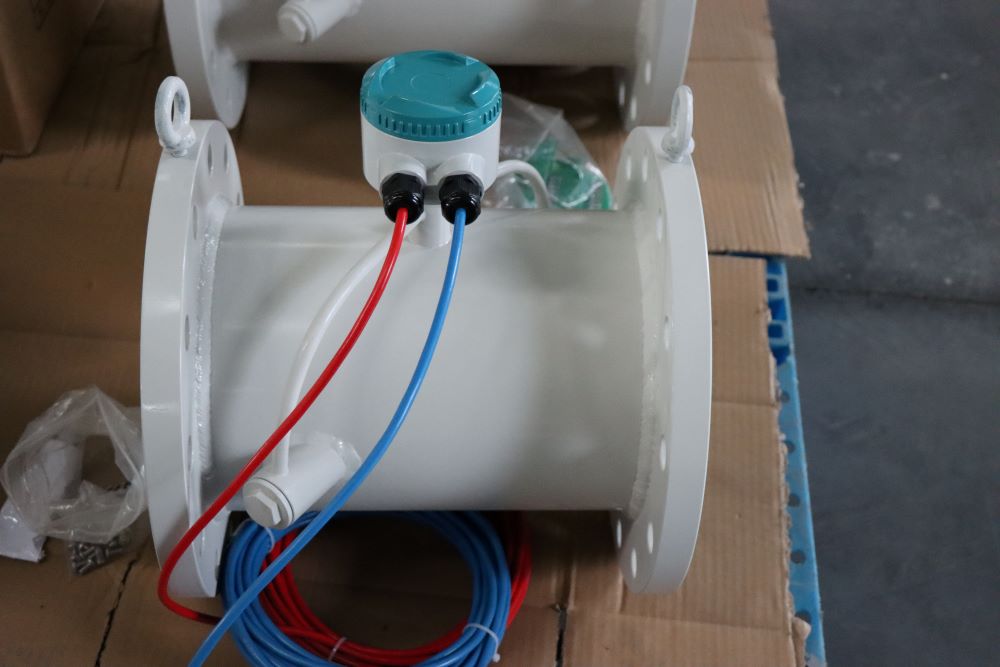

Electrode material: Stainless steel electrodes (such as 316L) usually meet the measurement requirements of domestic sewage. If the sewage is highly corrosive, more corrosion-resistant materials such as titanium electrodes or tantalum electrodes can be considered.

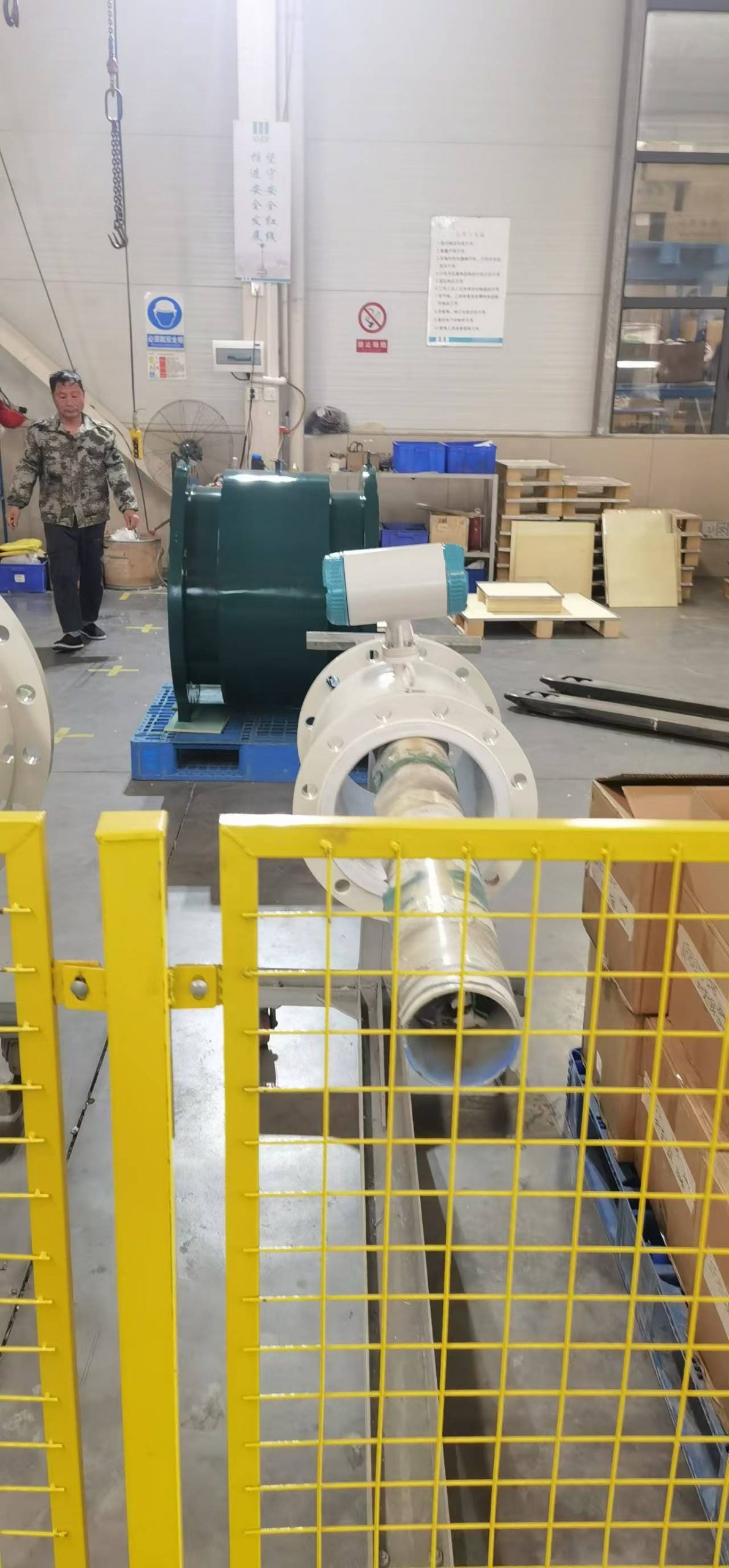

Installation method: Both integrated and split electromagnetic flowmeters are available for selection. The decision should be made based on the on-site installation conditions and personal preferences.

Ultrasonic flowmeter

Advantages: Ultrasonic flowmeters are suitable for large-diameter pipelines and situations where fluid contact is not easy. It does not need to come into direct contact with the medium and is convenient for installation and maintenance.

Key points for selection:

Type selection: The external clamp-on ultrasonic flowmeter can be directly attached to the outside of the pipeline and is suitable for occasions where it is difficult to stop the flow. The insertable type needs to be inserted into the pipe, which may cause certain damage to the pipe.

Measurement accuracy: Pay attention to the influence of impurities in the sewage on the propagation of ultrasonic waves, and select appropriate measurement methods and parameters to improve measurement accuracy.

Other flowmeters: Although vortex flowmeters, turbine flowmeters, etc. also have their application scenarios, they are relatively less used in the measurement of domestic sewage. Vortex flowmeters are susceptible to external interference, which can affect their measurement accuracy. Turbine flowmeters have higher requirements for the cleanliness of the medium and are not suitable for domestic sewage with a large amount of impurities.

3. Consider other factors

Measurement accuracy: Select the appropriate measurement accuracy grade based on actual needs. Generally speaking, electromagnetic flowmeters have relatively high measurement accuracy and can meet the measurement requirements of most domestic sewage.

Installation and maintenance: Consider the installation conditions of the flowmeter and the convenience of maintenance. Electromagnetic flowmeters are usually compact in structure and convenient to operate and maintain. Ultrasonic flowmeters do not need to come into direct contact with the medium, making their installation and maintenance simpler.

Cost-effectiveness: Taking into account factors such as the price, service life, and maintenance cost of the flowmeter comprehensively, select a product with high cost performance.