Non-full tube electromagnetic flowmeter: deciphered high-precision flow measurement technology

Non-full tube electromagnetic flowmeter is an advanced flow measuring instrument, especially suitable for measuring the flow of non-full tube or partially filled fluid, such as municipal rainwater, wastewater, sewage and so on. The following is a detailed introduction to the non-full tube electromagnetic flowmeter:

1. How it works

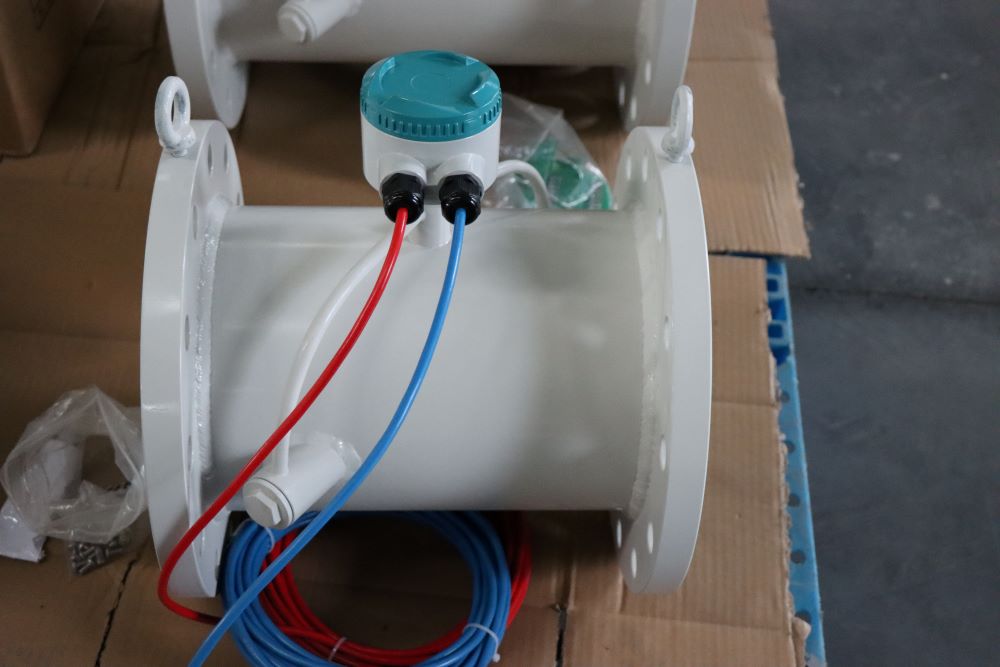

The non-full tube electromagnetic flowmeter is mainly based on the Faraday electromagnetic induction principle. When the liquid passes through the flowmeter pipe, the electrical conductivity in the liquid affects the magnetic field distribution in the fluid. The flow meter contains an electromagnetic coil transmitting and receiving coil and a receiving coil. The electromagnetic coil transmitting and receiving coil generates a magnetic field by passing a certain current, and the receiving coil is used to detect changes in the magnetic field. As the liquid flows through the flow meter, the electrical conductivity in the liquid changes the distribution of the electromagnetic field, and the receiving coil calculates the flow rate in the liquid by detecting this change.

2. Characteristics and advantages

High precision: non-full tube electromagnetic flowmeter adopts mature electromagnetic induction technology, has high measurement accuracy and stability, and can achieve accurate measurement of fluid flow.

Wide range of adaptability: Suitable for a variety of complex environments, including pipes of different diameters, materials and inclinations, as well as fluids containing solid particles, suspended solids or bubbles.

Versatility: It can not only measure the flow rate, but also calculate the density, temperature and solid content of the fluid by measuring parameters such as conductivity and temperature, providing more basis for the control and regulation of industrial processes.

Small resistance: The flow meter has a simple structure and small size, and the resistance generated when the fluid passes through is small, and the impact on the pipeline system is small.

Remote monitoring and management: Combined with the Internet of Things technology, remote monitoring and data transmission can be achieved to facilitate real-time understanding of traffic and management.

3. Application field

Non-full tube electromagnetic flowmeter is widely used in the following fields:

Industrial production: In the chemical, petroleum, pharmaceutical, food, textile, paper and other industries process control and quality monitoring, to ensure the normal operation of the production process.

Environmental monitoring: In the environmental protection and water treatment industry, it is used for sewage treatment, water resources management, river flow measurement, etc., to effectively control wastewater discharge and water resources utilization.

Automatic control: Suitable for automatic control system, can be used with PLC, DCS and other equipment to achieve real-time monitoring and control of flow.

Experimental research: In the field of scientific research, it is often used in fluid mechanics experiments, biomedical research and other aspects to provide non-contact flow measurement methods.

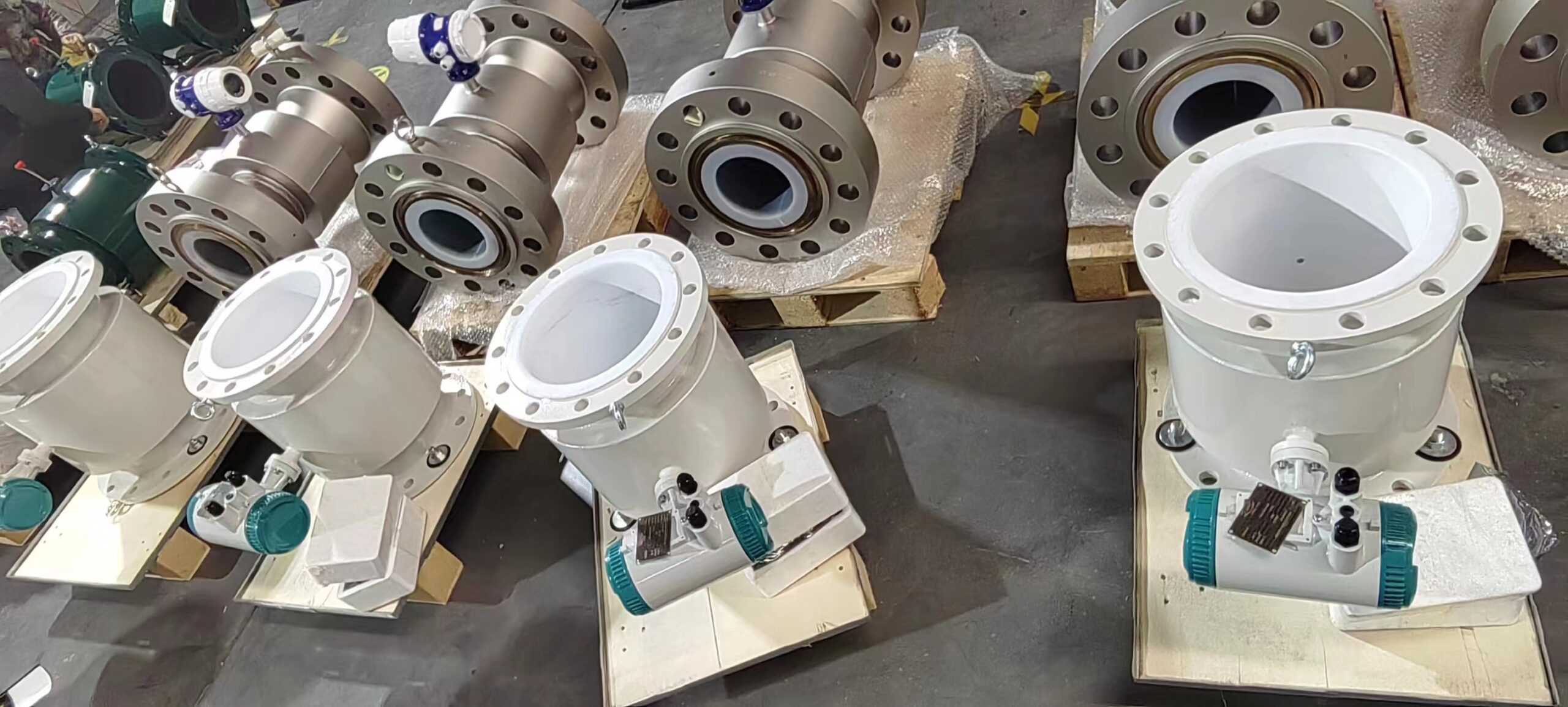

4. Selection and installation

When selecting, factors such as flow range, pipe diameter, material, accuracy requirements and output signal need to be considered to ensure the selection of the right model and configuration. When installing, it is necessary to pay attention to the influence of factors such as the geometric size, material and arrangement of the pipeline on the measurement accuracy, and make the correct selection and adjustment.

In short, the non-full tube electromagnetic flowmeter is a reliable and accurate flow measurement instrument, with high precision, wide adaptability, versatility and other advantages, in industrial production, environmental monitoring, automation control and other fields play an important role.