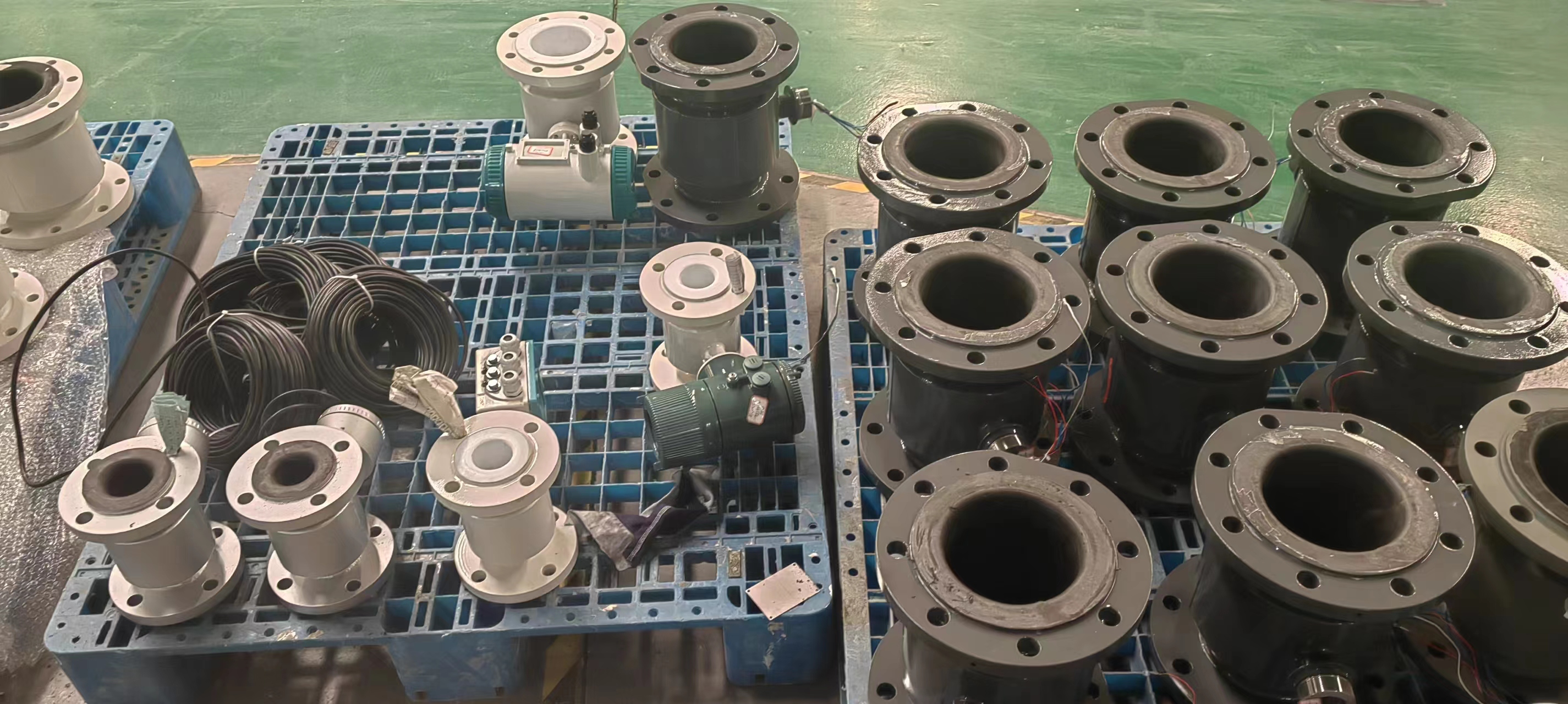

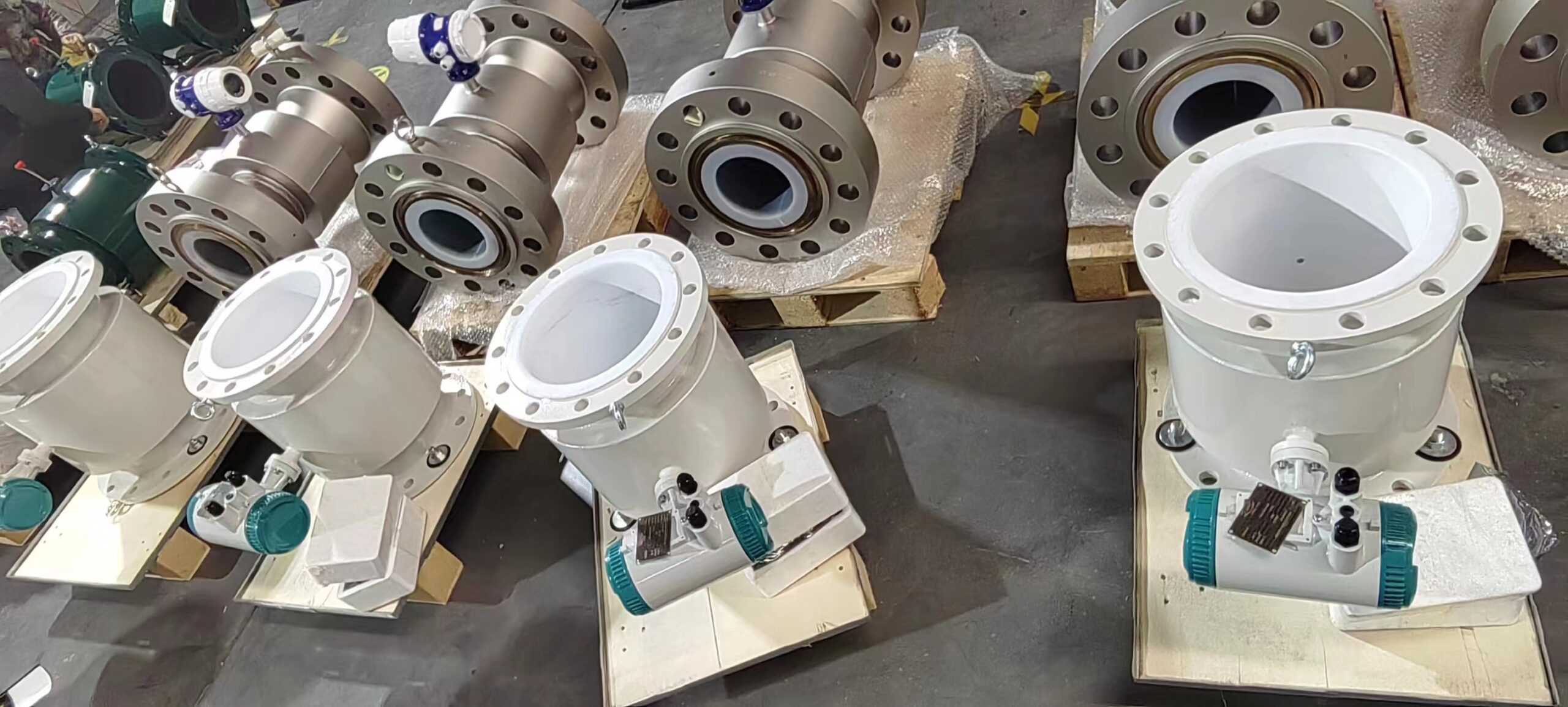

Flanged Clamped or Insertion Electromagnetic Flowmeters for Conductive Liquid SS316 Hc Hb

Installing electromagnetic flowmeters correctly is essential for ensuring accurate and reliable flow measurement. Here are some precautions to consider when installing electromagnetic flowmeters:

Proper Alignment: Ensure that the flowmeter is installed correctly with the flow direction aligned as per the manufacturer’s instructions. Incorrect alignment can lead to inaccuracies in flow measurement.

Straight Pipe Lengths: Provide sufficient straight pipe lengths upstream and downstream of the flowmeter to ensure a fully developed flow profile. The recommended lengths vary depending on the pipe diameter and flow conditions specified by the manufacturer.

Pipe Orientation: Install the flowmeter in a horizontal pipe section whenever possible. Avoid vertical or inclined orientations to prevent air pockets or gas entrapment, which can affect measurement accuracy.

Grounding: Properly ground the flowmeter to minimize electrical noise and interference. Follow the grounding guidelines provided by the manufacturer to ensure accurate measurements and protect against damage from static electricity.

Avoid Obstructions: Install the flowmeter away from obstructions such as valves, pumps, elbows, or tees that can cause flow disturbances or turbulence. Maintain a clear space around the flowmeter to facilitate proper fluid flow and measurement accuracy.

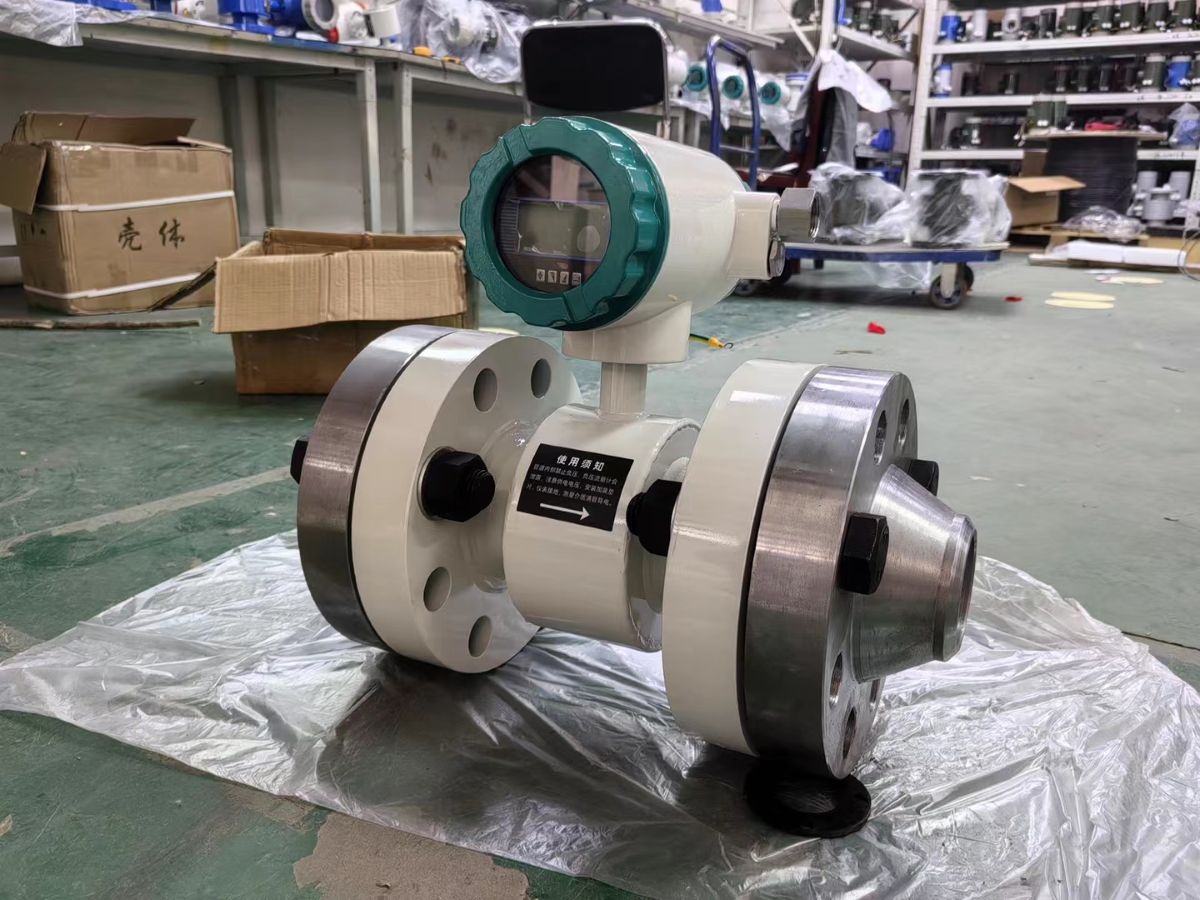

Liner Condition: Inspect the flowmeter liner for any damage or defects before installation. Ensure that the liner material is compatible with the fluid being measured to prevent corrosion or degradation over time.

Electrode Position: Verify that the electrode tips are positioned correctly and securely fastened within the flowmeter. Misalignment or loose electrodes can result in inaccurate measurements or signal instability.

Calibration: Calibrate the flowmeter according to the manufacturer’s specifications before putting it into service. Regular calibration checks may be necessary to maintain measurement accuracy over time.

Temperature and Pressure Limits: Ensure that the operating temperature and pressure of the fluid fall within the specified limits of the flowmeter. Exceeding these limits can affect the performance and longevity of the flowmeter.

Sealing and Leak Testing: Properly seal all connections and joints to prevent leaks that can compromise measurement accuracy or cause safety hazards. Conduct leak tests after installation to verify the integrity of the system.

Environmental Considerations: Consider environmental factors such as temperature variations, moisture, vibration, and exposure to chemicals or corrosive substances when selecting the installation location and protective measures for the flowmeter.