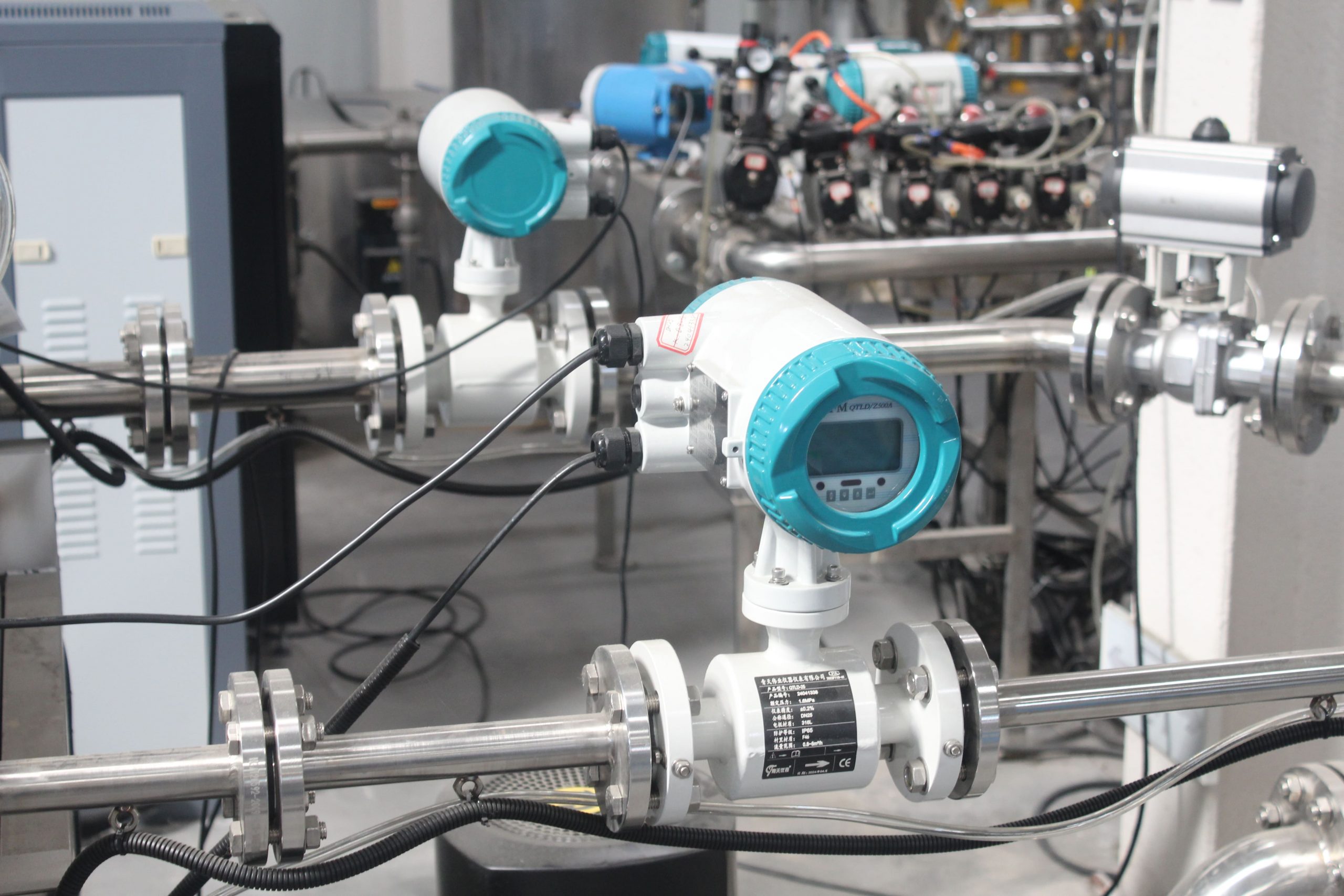

Installation instructions of electromagnetic flow meter

The installation of the electromagnetic flowmeter depends on the requirements of the customer’s working conditions, and then select the type, and install it according to the instructions or the guidance of the flowmeter manufacturer’s staff. The following points need to be noted when installing the electromagnetic flowmeter:

1. The liquid should have the electrical conductivity required for measurement. And the conductivity distribution is required to be generally uniform. Therefore, the installation of the flow transmitter should avoid the place where the electrical conductivity is easy to produce uneven, such as adding the liquid near its upstream, and the filling point is located downstream of the transmitter.

2. The transmitter measuring tube must be filled with liquid (except for the non-full tube type). The transmitter should be installed where the measuring tube can be filled with liquid at all times to prevent the illusion that the pointer is not in zero position because there is no liquid in the measuring tube. The measuring tube is installed vertically, allowing the measured liquid to flow through the meter from bottom to top. In this way, measurement errors caused by sediment in the conduit or bubbles in the medium can be avoided. If it cannot be installed vertically, it can also be installed horizontally. But keep the two electrodes at the same level.

3. The signal of the electromagnetic flowmeter is relatively weak, only 2.5 ~ 8mV at full scale, the flow rate is very small, the output is only a few microvolts, and the external interference can affect the accuracy of the measurement. Therefore, the transmitter housing, shielding wire, measuring conduit, and the pipeline at both ends of the transmitter should be grounded. The ground point is required to be set separately, and it is absolutely not connected to the public ground line or upper and lower water pipes of the motor, electrical appliances, etc. The conversion part has been grounded through the cable, so it should be grounded again. So as not to introduce interference due to the difference of ground potential.