Advantages and disadvantages of electromagnetic flow meter

Electromagnetic flowmeter is a kind of induction instrument which measures the volume flow of conductive medium in tube according to Faraday’s law of electromagnetic induction. The electromagnetic flowmeter adds a magnetic field on both sides of the pipeline, and the measured medium flows through the pipeline to cut the magnetic force line, generating an induced potential on the two detection electrodes, and its size is proportional to the speed of fluid movement.

Electromagnetic flowmeter is a kind of induction instrument which measures the volume flow of conductive medium in tube according to Faraday’s law of electromagnetic induction. The electromagnetic flowmeter adds a magnetic field on both sides of the pipeline, and the measured medium flows through the pipeline to cut the magnetic force line, generating an induced potential on the two detection electrodes, and its size is proportional to the speed of fluid movement.

The advantages of electromagnetic flowmeter are:

1, electromagnetic flowmeter can be used to measure industrial conductive liquid or slurry.

2, no pressure loss.

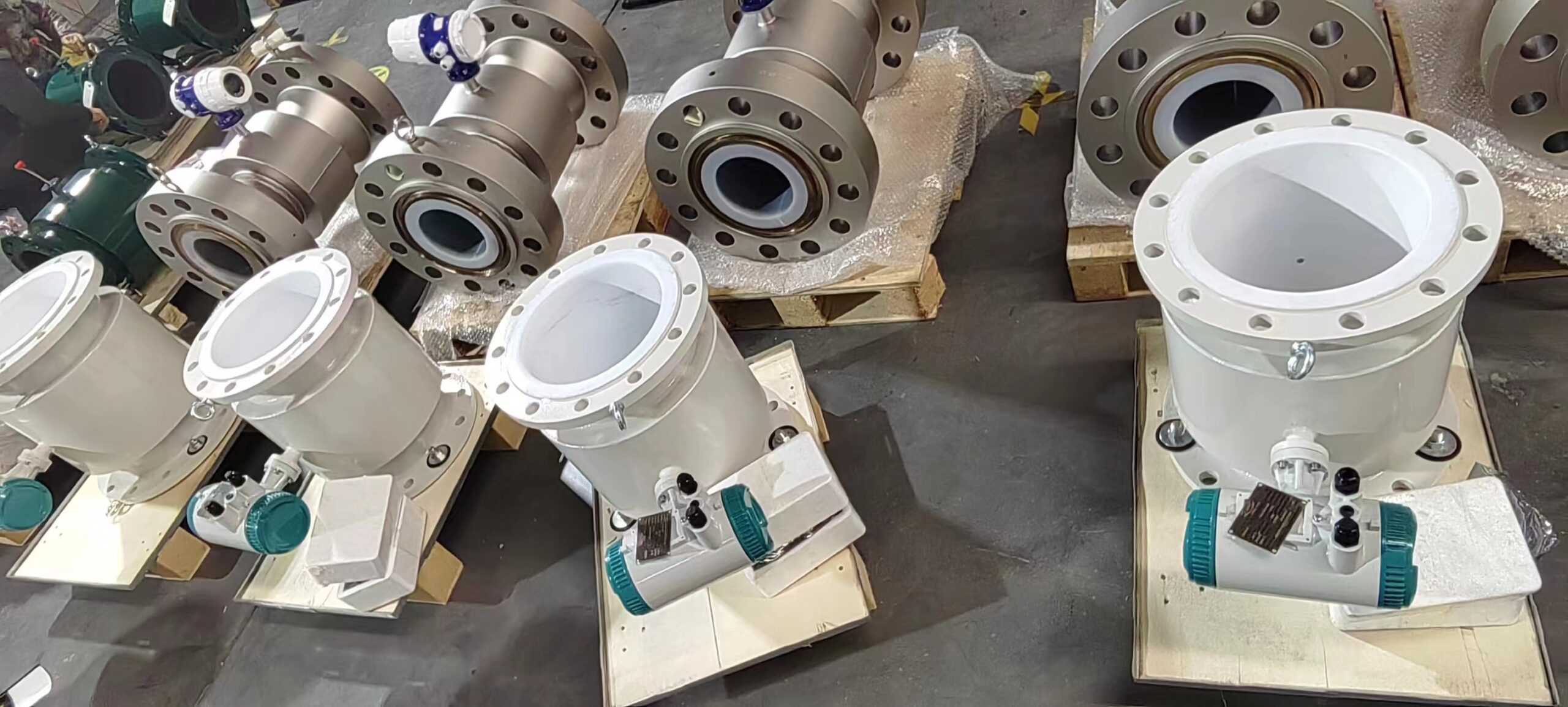

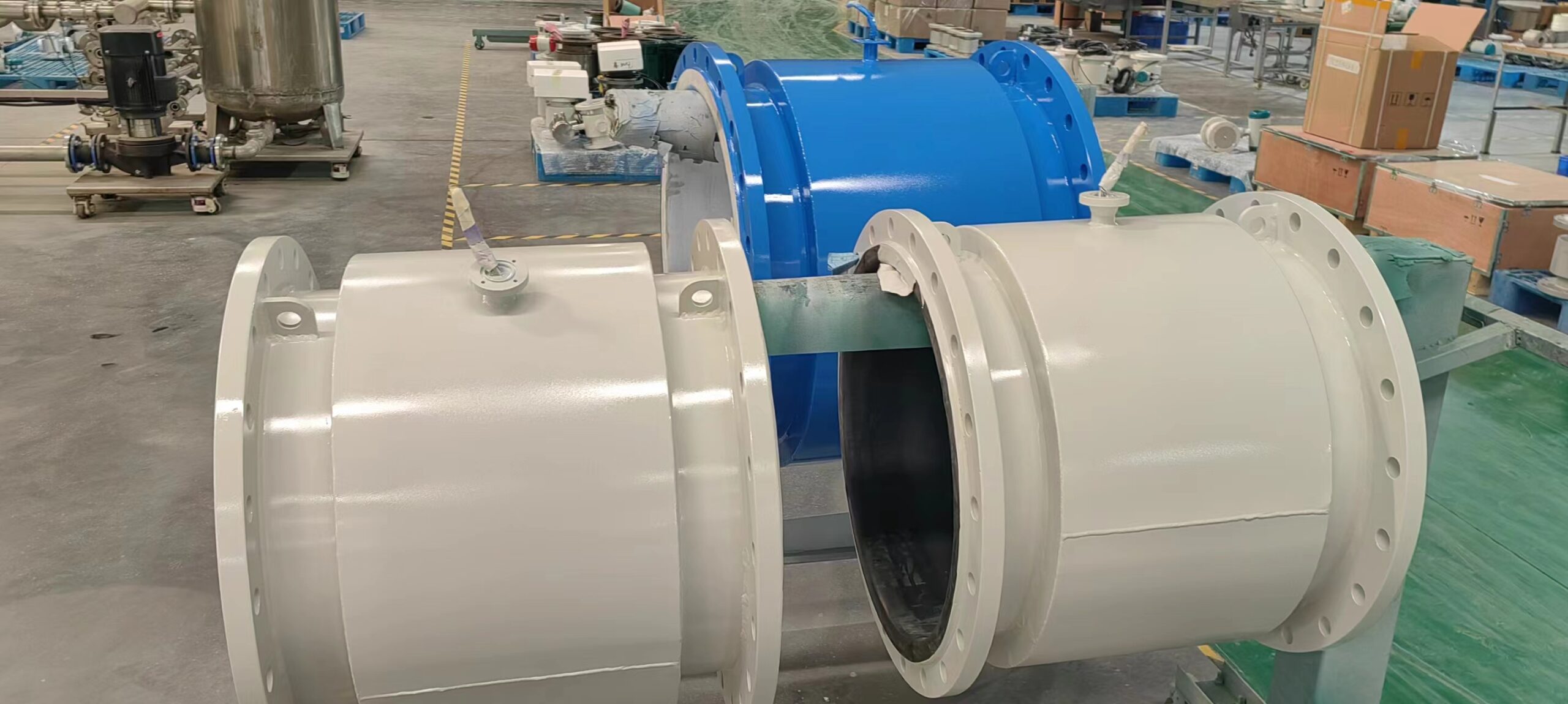

3, the measuring range is large, the diameter of the electromagnetic flow transmitter is from 2.5mm to 2.6m.

4, the electromagnetic flowmeter measures the volume flow of the measured flow body under the working state, the measurement principle does not involve the influence of fluid temperature, pressure, density and viscosity.

The disadvantages of electromagnetic flowmeter are:

1, the application of electromagnetic flowmeter has certain limitations, it can only measure the liquid flow of conductive media, can not measure the flow of non-conductive media, such as gas and water treatment good heating water. In addition, the lining should be considered under high temperature conditions.

2, the electromagnetic flowmeter is to determine the volume flow under the working state by measuring the speed of the conductive liquid. According to the measurement requirements, for the liquid medium, the mass flow rate should be measured, and the measurement of the medium flow rate should involve the density of the fluid, and different fluid media have different densities, and change with temperature. If the electromagnetic flowmeter converter does not consider the fluid density, it is not appropriate to give only the volume flow rate at room temperature.