How to maintain the sensor of a steam flowmeter

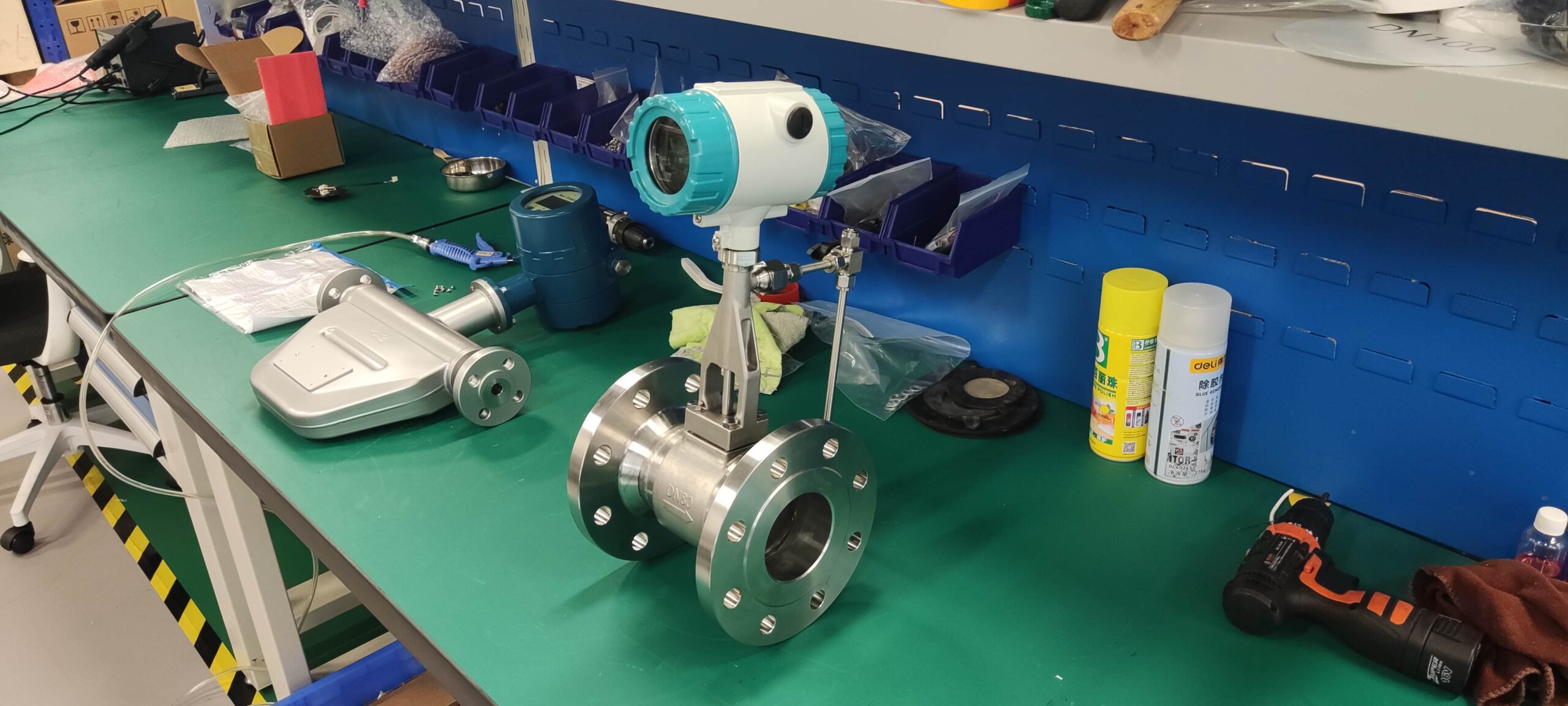

Steam flowmeters are mainly used for measuring the flow of steam medium fluids in industrial pipelines. The product features low pressure loss, wide measurement range, high accuracy, and is almost unaffected by parameters such as fluid density, pressure, temperature, and viscosity when measuring the volume flow under working conditions. There are no moving mechanical parts, so it has high reliability and low maintenance.

How to maintain the sensor of a steam flowmeter

Before installing the sensor, first check if the steam flowmeter shows any display. Install the sensor when there is a display. If it is not displayed, please check the relevant components and troubleshoot.

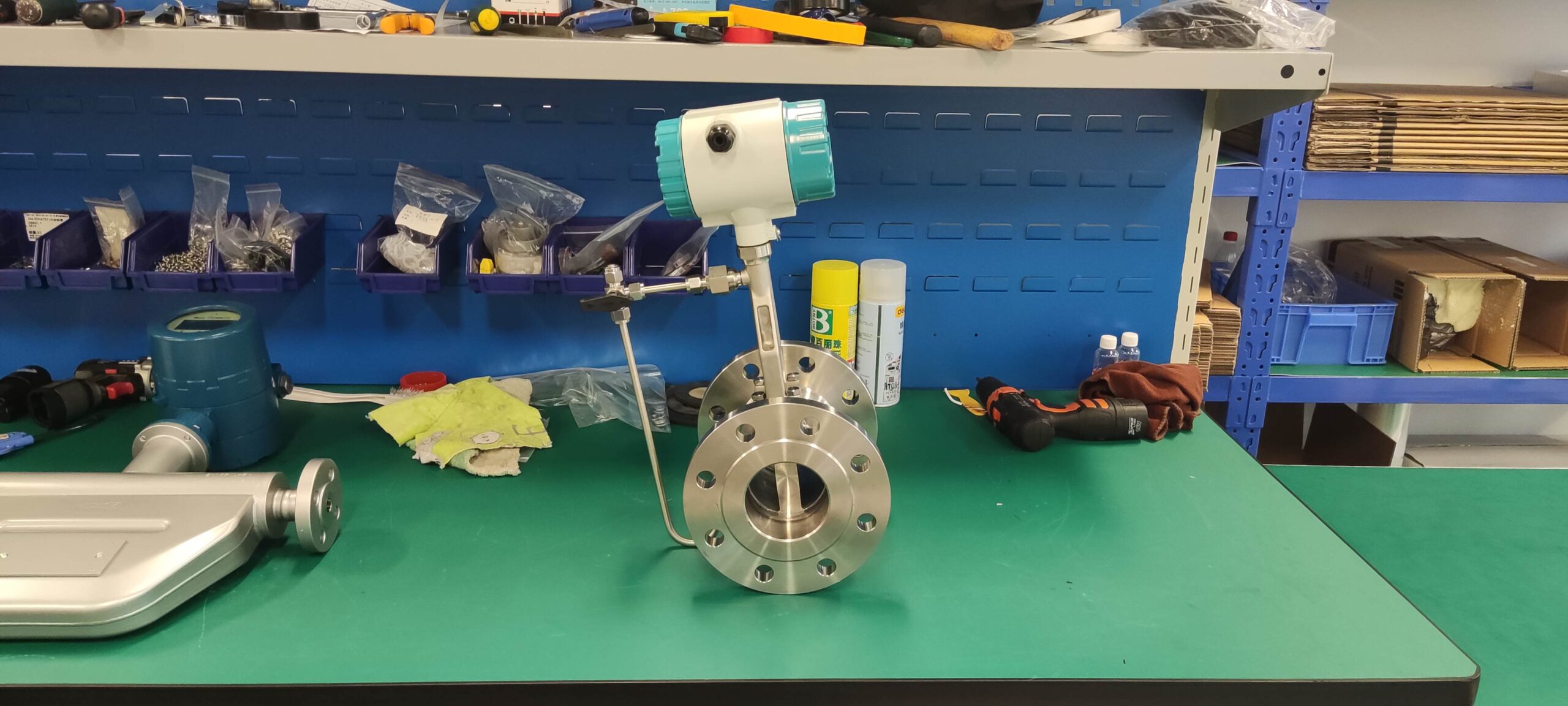

2. When in use, keep the medium being measured clean and free of impurities such as fibers and particles.

3. When in use, the sensor should be slowly filled with medium, and then the outlet valve (the valve should be installed at the rear end of the flowmeter) should be opened. When the sensor is in a state without medium, it must not be affected by high-speed fluid.

5. When not in use, the internal medium should be cleaned. After drying, protective covers should be added to both ends of the sensor to prevent dust from entering, and then it should be stored in a dry place.

6. The filters used in the steam flowmeter should be cleaned regularly. When not in use, the internal medium should be cleaned. Like the sensor, add a dust cover and store it in a dry place.