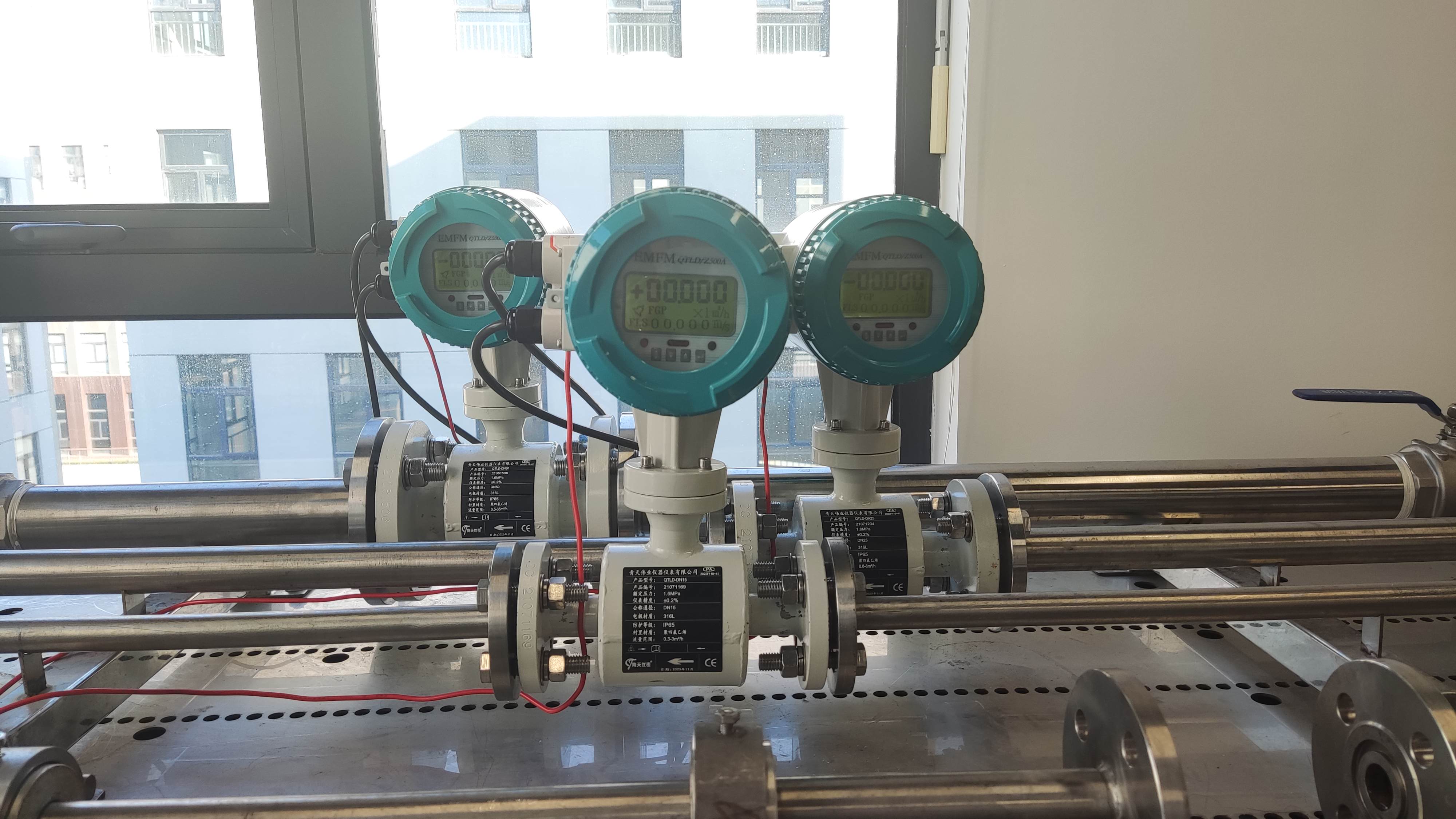

The straight pipe sections before and after the electromagnetic flowmeter

The requirements for the straight pipe sections before and after the electromagnetic flowmeter are crucial for ensuring the accuracy and stability of the measurement results. The following is a detailed analysis of the requirements for the straight pipe sections before and after the electromagnetic flowmeter:

Requirements for the straight pipe section before the electromagnetic flowmeter

Length requirement:

Generally speaking, the length of the straight pipe section before an electromagnetic flowmeter should be at least 2 to 5 times the pipe diameter, depending on the model of the flowmeter, the accuracy requirements, and the characteristics of the fluid inside the pipe. Longer straight pipe sections help ensure that the fluid has reached a stable flow state before flowing through the electromagnetic flowmeter, reducing the influence of vortices and pulsations on the measurement results.

In certain specific circumstances, such as when the fluid medium is relatively viscous or the flow rate is low, a longer front straight pipe section may be required to ensure the accuracy of the measurement.

Other requirements:

The straight pipe sections should be ensured to have no obvious bends, manifolds or throttling devices to avoid the disorder of fluid flow and the generation of vortices.

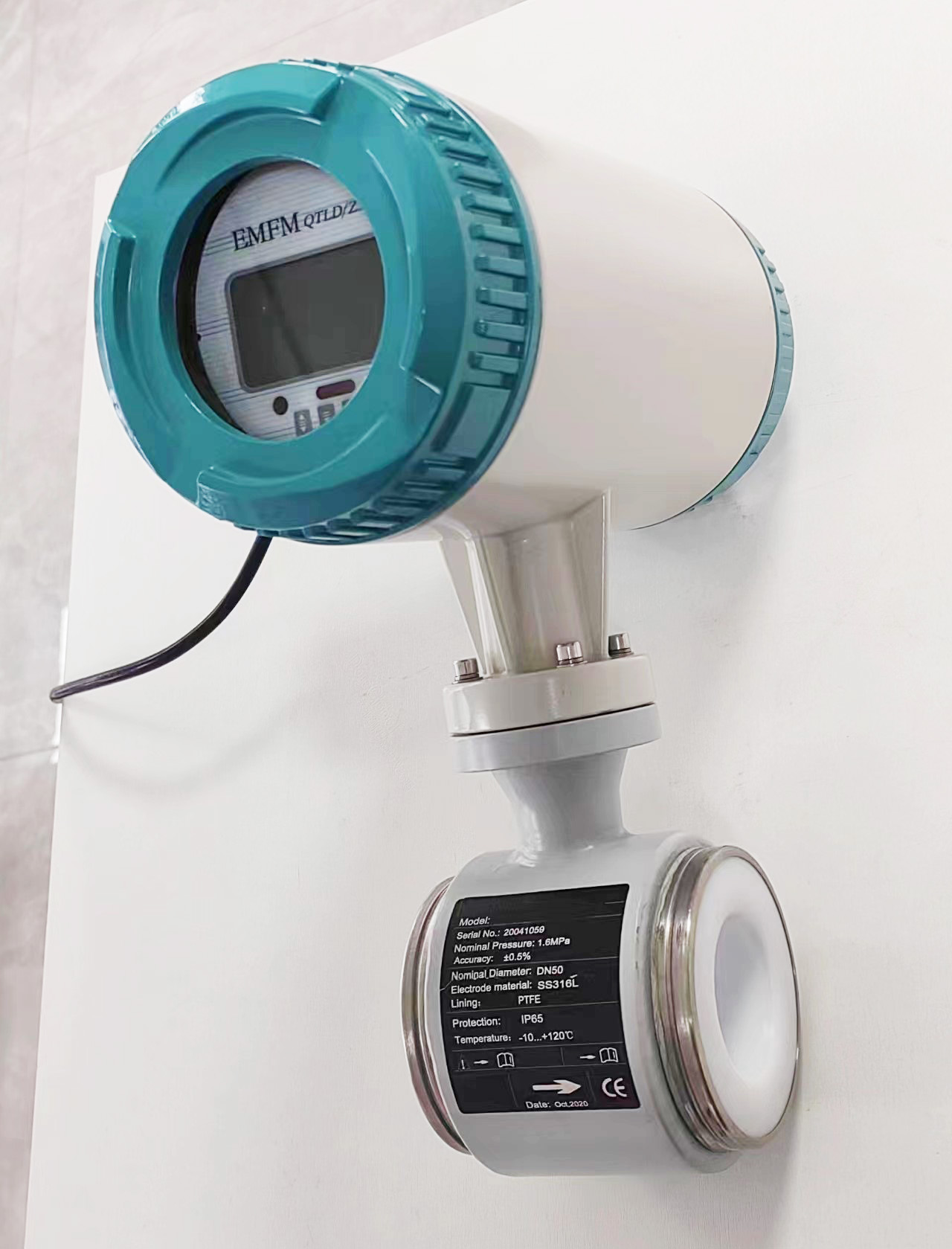

The inner wall of the pipe should be kept smooth to reduce frictional resistance and the resistance of fluid flow, and improve the measurement accuracy.

Before installation, the pipes should be cleaned to ensure there are no impurities or dirt inside, so as to avoid clogging the pipes or affecting the stability of fluid flow.

2. Requirements for the straight pipe section behind the electromagnetic flowmeter

Length requirement:

The length of the straight pipe section after the electromagnetic flowmeter should generally be at least 1 to 3 times the pipe diameter to ensure that the fluid can maintain a stable flow state after passing through the electromagnetic flowmeter and avoid the influence of uneven flow velocity distribution on the measurement results.

The length of the straight pipe section at the back should also be adjusted according to the model and accuracy requirements of the flowmeter to ensure the stability and accuracy of the measurement results.

Other requirements:

It is also necessary to avoid unfavorable factors such as bending, manifolds or truncation in the rear straight pipe section to reduce the resistance of fluid flow and the generation of vortices.

Maintain the stability of the rear straight pipe section to avoid instability in fluid flow due to vibration and other reasons, which may affect the measurement results.

Summary: The requirements for the straight pipe sections before and after the electromagnetic flowmeter mainly include length requirements and other special requirements. The accuracy and stability of flow measurement can be improved by ensuring a sufficient length of straight pipe sections and avoiding the existence of unfavorable factors such as bending, manifolds and truncation. At the same time, the pipeline should be cleaned before installation, and the electromagnetic flowmeter should be inspected and calibrated after installation to ensure its measurement accuracy and reliability.