The structure of electromagnetic flow meter and the function of each component

According to the composition of the sensor and the converter, the electromagnetic flowmeter can be divided into two types: separation type and one type. The separation type is to set the sensor and the converter independently, and the middle is connected with a cable, so the cable length is limited by the conductivity of the measured current body. One type is the sensor and converter as a whole set, so it is related to the fluid temperature and the ambient temperature, compared with the separation type, the applicable temperature range will be limited.

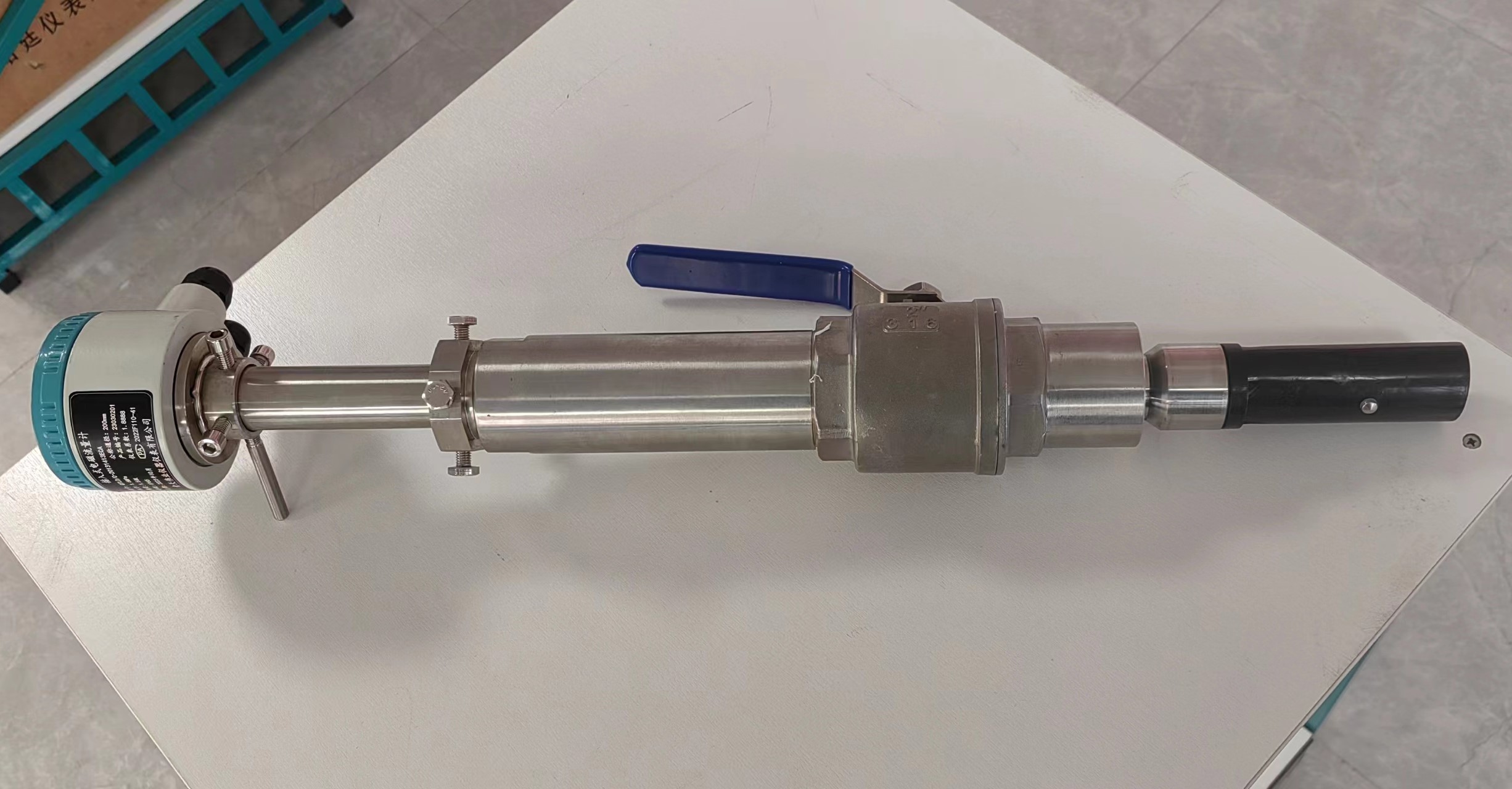

The basic structure of electromagnetic flowmeter

According to the composition of the sensor and the converter, the electromagnetic flowmeter can be divided into two types: separation type and one type. The separation type is to set the sensor and the converter independently, and the middle is connected with a cable, so the cable length is limited by the conductivity of the measured current body. One type is the sensor and converter as a whole set, so it is related to the fluid temperature and the ambient temperature, compared with the separation type, the applicable temperature range will be limited.

The name and function of the main components of the electromagnetic flowmeter are as follows:

1. Shell

Prevent mechanical damage to the excitation coils, core and electrode wires inside the sensor of the electromagnetic flowmeter and protect it from the surrounding environment. Its structure must have sufficient mechanical strength to prevent the intrusion of water and dust, and resist the corrosion of the surrounding environment of the installation site.

2. Measuring tube

The structure must form a conduit that flows through the flow being measured and can mechanically withstand the strength of the fluid pressure.

3. Lining

It is the insulation of the measuring tube lining of the electromagnetic flowmeter to prevent the signal electromotive force from being short-circuited. Because the lining material is in contact with the current being measured, it must be a material that can wear and resist corrosion. In addition, the lining is subject to the upper limit of the fluid temperature according to its material properties.

4. Electrode

Mount on the wall of the measuring tube to remove the electrode voltage. The electrode material must be resistant to fluid wear and corrosion.

5. Connect the liquid ring

It can make the electromagnetic flowmeter sensor and the measured liquid equal potential, and also has the role of protecting the flange end lining. The material must be resistant to fluid wear and corrosion.

6, excitation coil and iron core

It forms a flux density in the measuring tube that is proportional to the excitation current of the sensor.

-.jpg)