Installation requirements of electromagnetic flow meter in sewage treatment

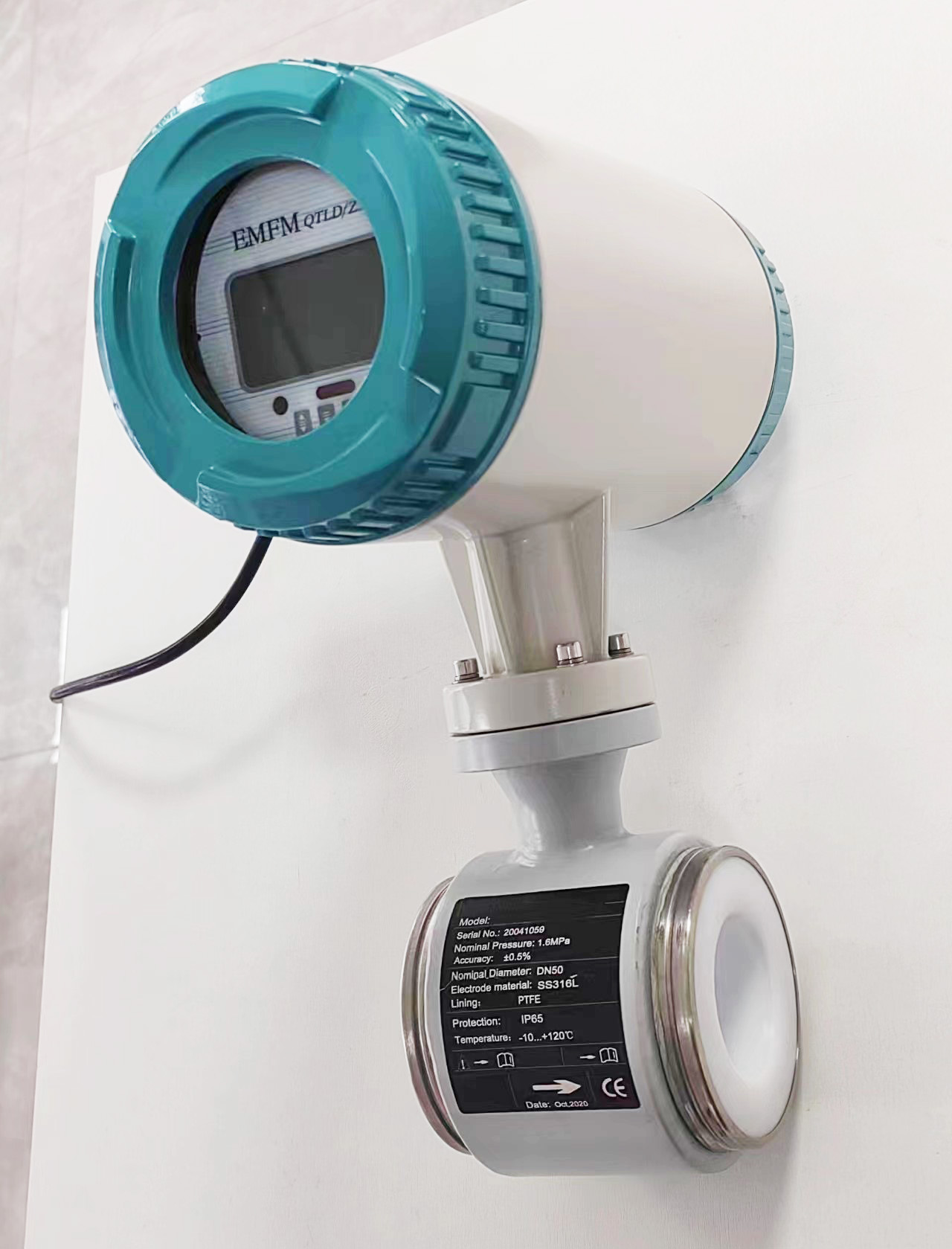

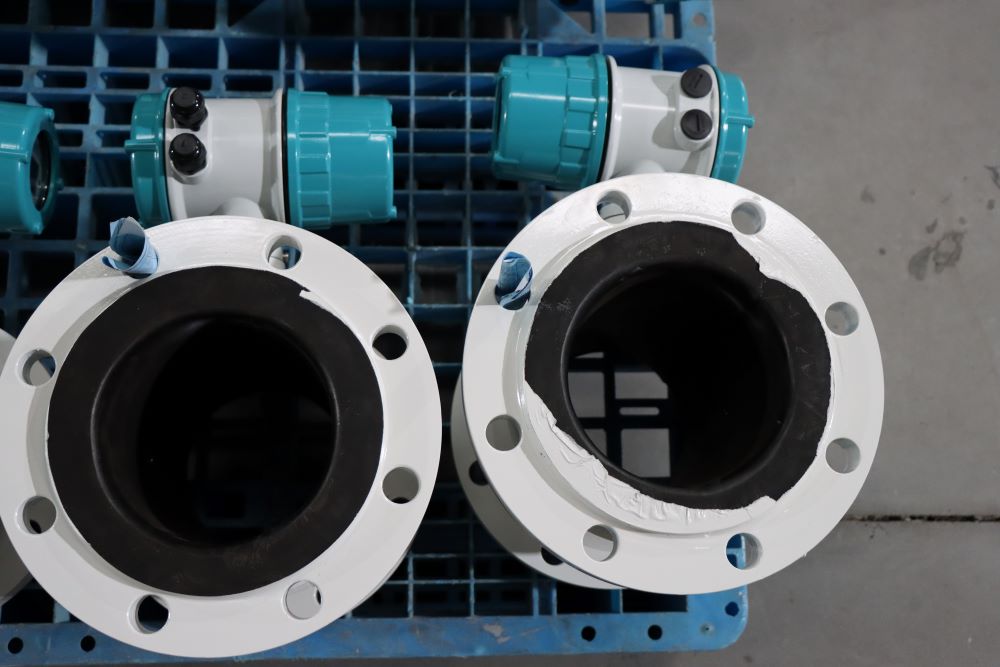

Electromagnetic flowmeters are mainly used to measure the volume flow of conductive liquid and slurry in closed pipelines, including the volume flow of acid, alkali, salt and other highly corrosive liquids.

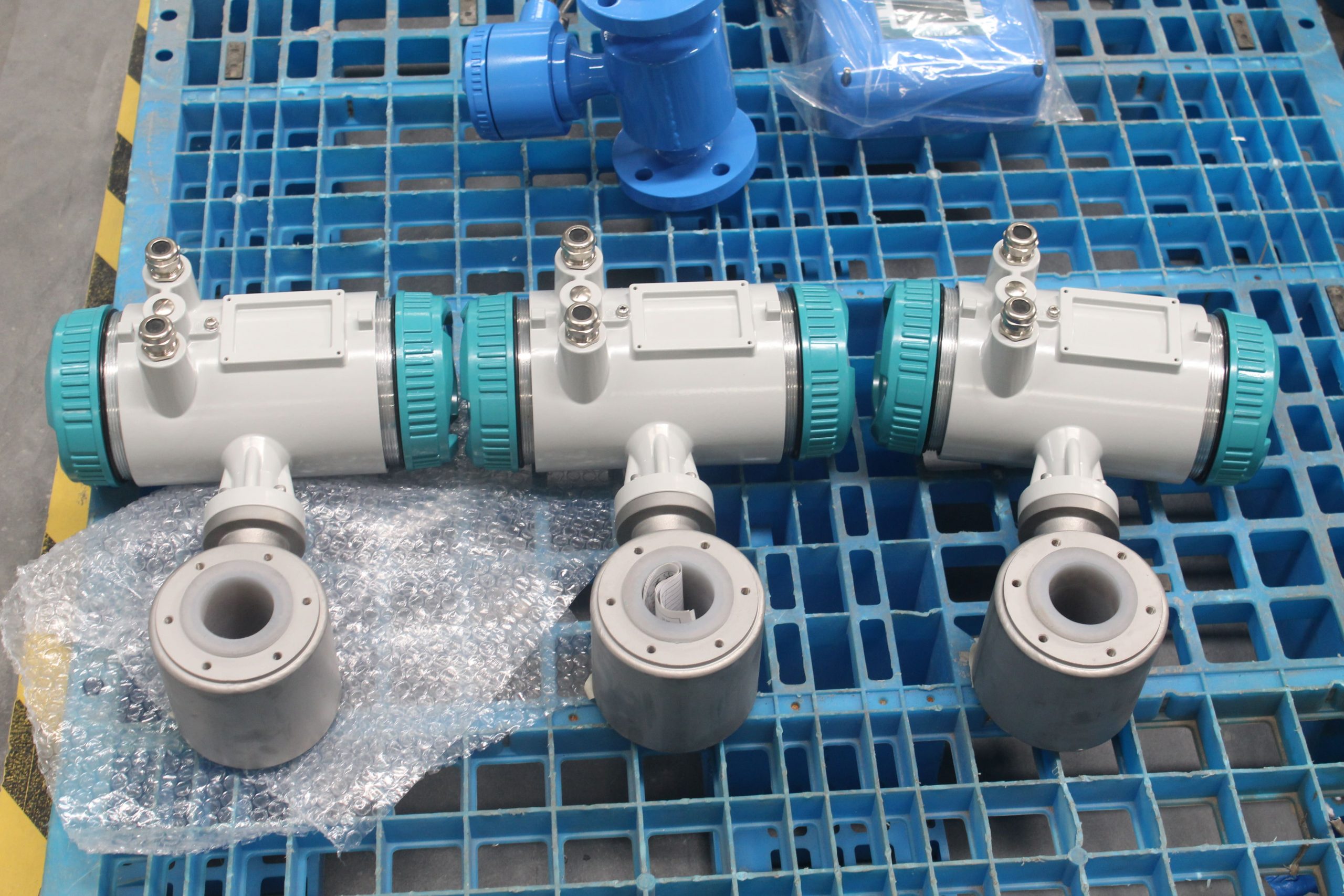

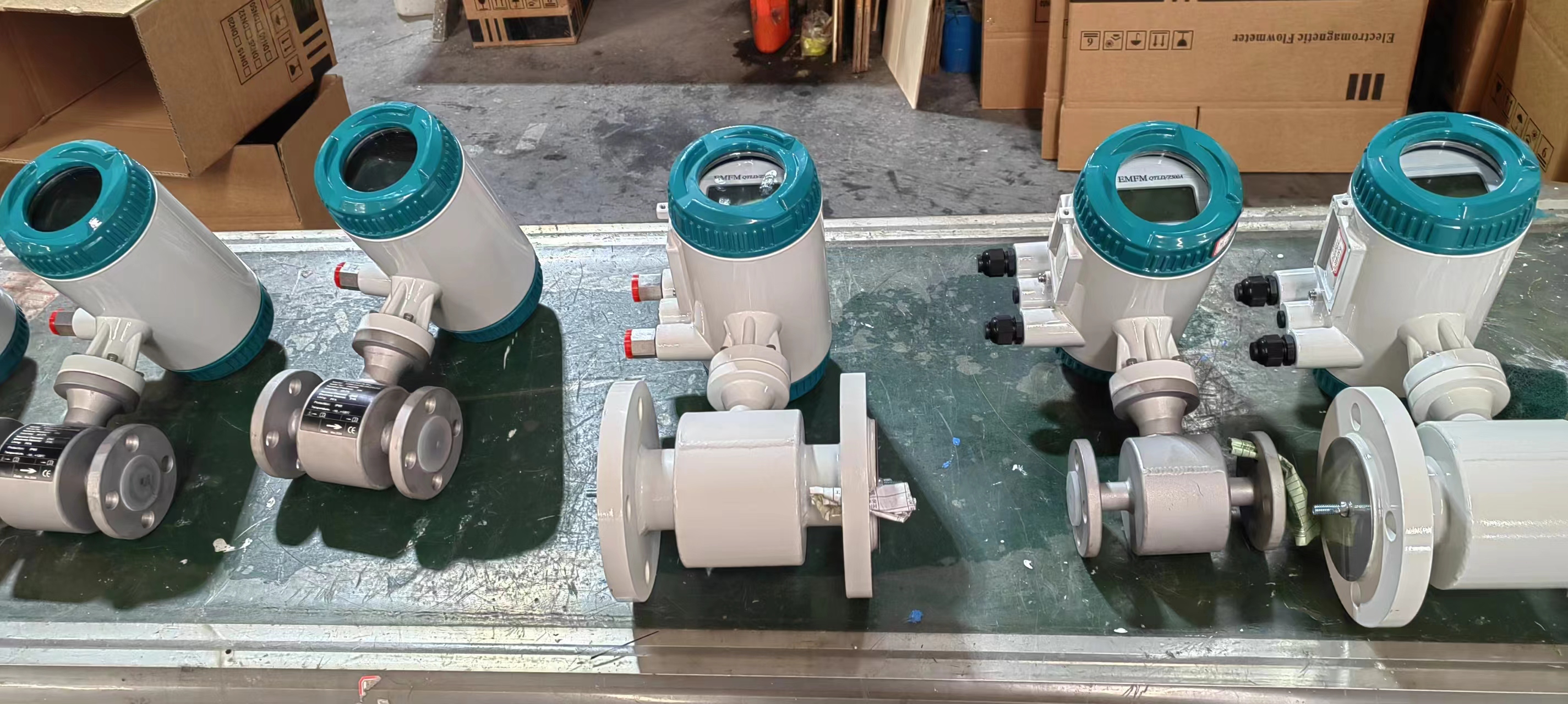

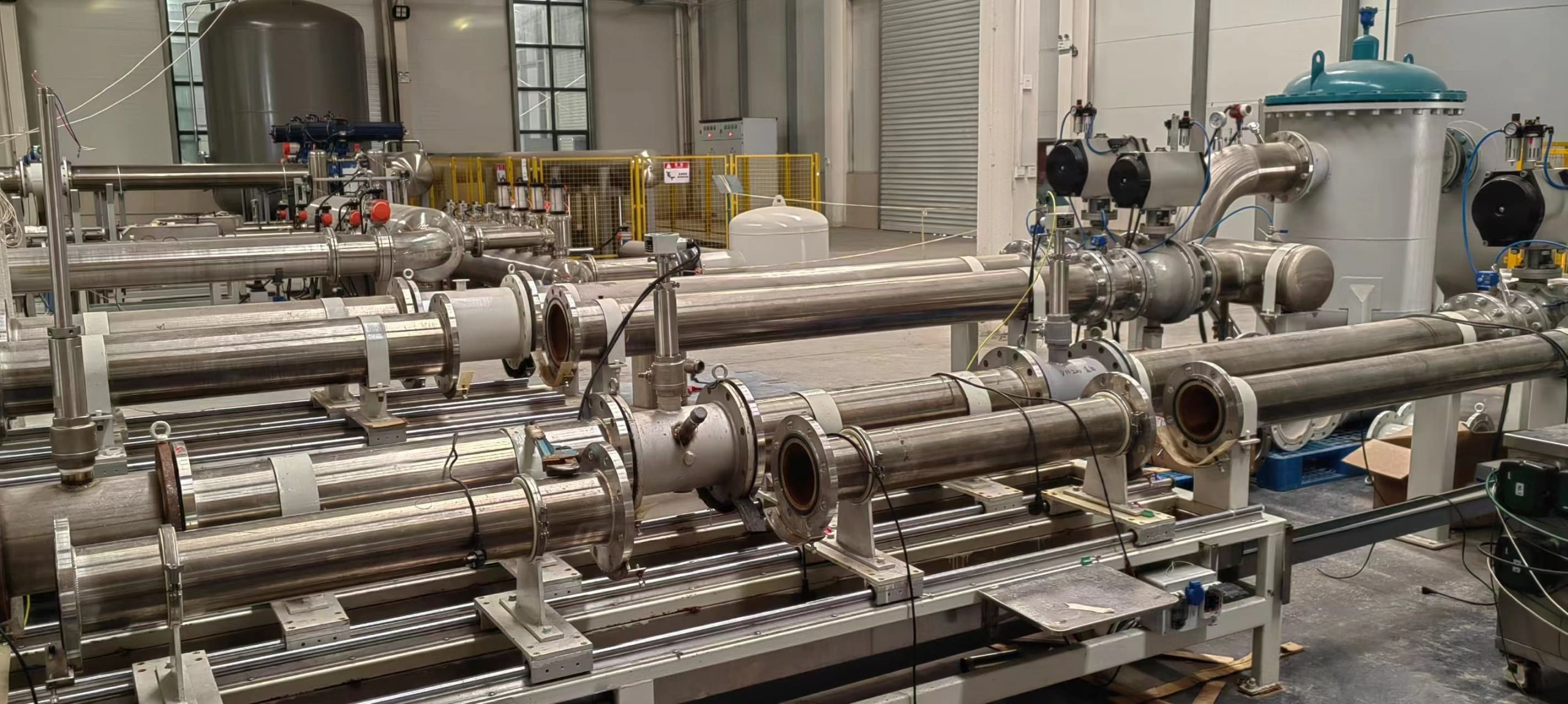

In the sewage industry, electromagnetic flowmeters as small as DN15, as large as DN2000 caliber of a variety of products. The process of sewage treatment is mainly through biological oxidation, flocculation, precipitation and other processes to achieve the purpose of sewage purification, and a certain quantity meter is required at each stage to measure.

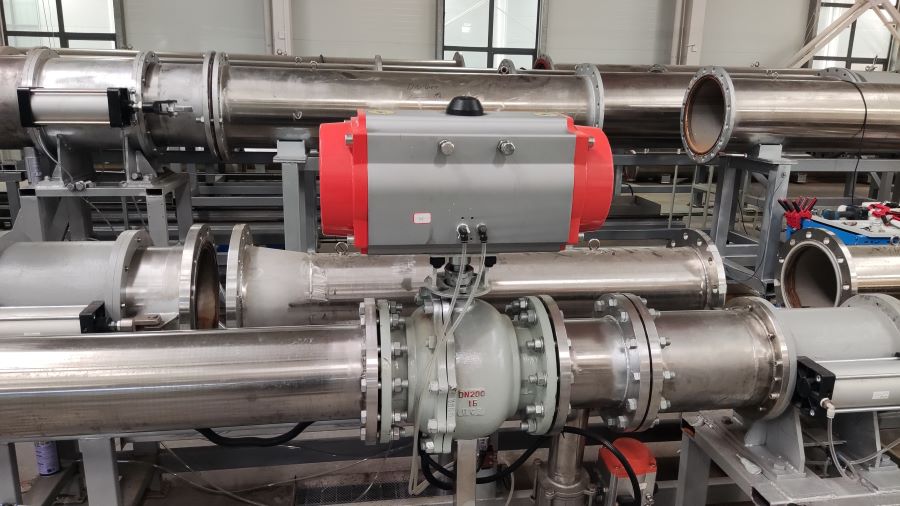

In sewage plants, large diameter flowmeter sensors are mostly installed underground, so it is recommended to choose IP68(dustproof and submersible level).

Usually the electromagnetic flowmeter has the following requirements for the installation site:

1) When measuring mixed phase fluids, choose a place that will not cause phase separation; When measuring two-component liquids, avoid loading downstream where the mixture has not been uniform; When measuring the chemical reaction pipe, it should be installed downstream of the reaction fully completed section; Try to meet the front and back straight pipe segments are not less than 5D and 2D respectively;

2) As far as possible to avoid the measurement tube into negative pressure;

3) Choose a place with small vibration, especially for a type instrument;

4) Avoid large motors and transformers nearby, so as not to cause electromagnetic field interference;

5) A place where the sensor is easily grounded separately;

6) Avoid high-concentration corrosive gases in the surrounding environment as much as possible;

7) Avoid direct sunlight if possible

In the sewage treatment process, it is necessary to configure the corresponding detection instrument according to the process requirements to form a reliable control system. Many parts of the wastewater treatment plant are equipped with electromagnetic flowmeters in the following process inspection processes:

1. Water inlet pipe;

2, the initial sedimentation tank to the mud storage tank mud amount detection;

3. Measurement of sludge discharge from digester;

4, digestion tank sludge amount detection;

5, sludge pump room surplus, sludge flow detection;

6, sludge pump room return sludge flow test;

7. Water flow detection of the distribution well of the secondary sedimentation basin;

8, flocculation tank reagent intake detection and so on.

The above is about the installation requirements of electromagnetic flowmeters in sewage treatment, and I hope it will be helpful to you.