How to select the appropriate steam flowmeter for different working conditions

In the future operation of steam flowmeters, the inaccurate measurement or unusable situations caused by incorrect selection should be greatly reduced. The following points should be noted:

1. The heating company should install a meter with high measurement accuracy and wireless meter reading function to prevent problems of underrecording and omission. It can also keep track of the changes in actual pressure, temperature and flow rate of each user at any time, thereby improving economic benefits.

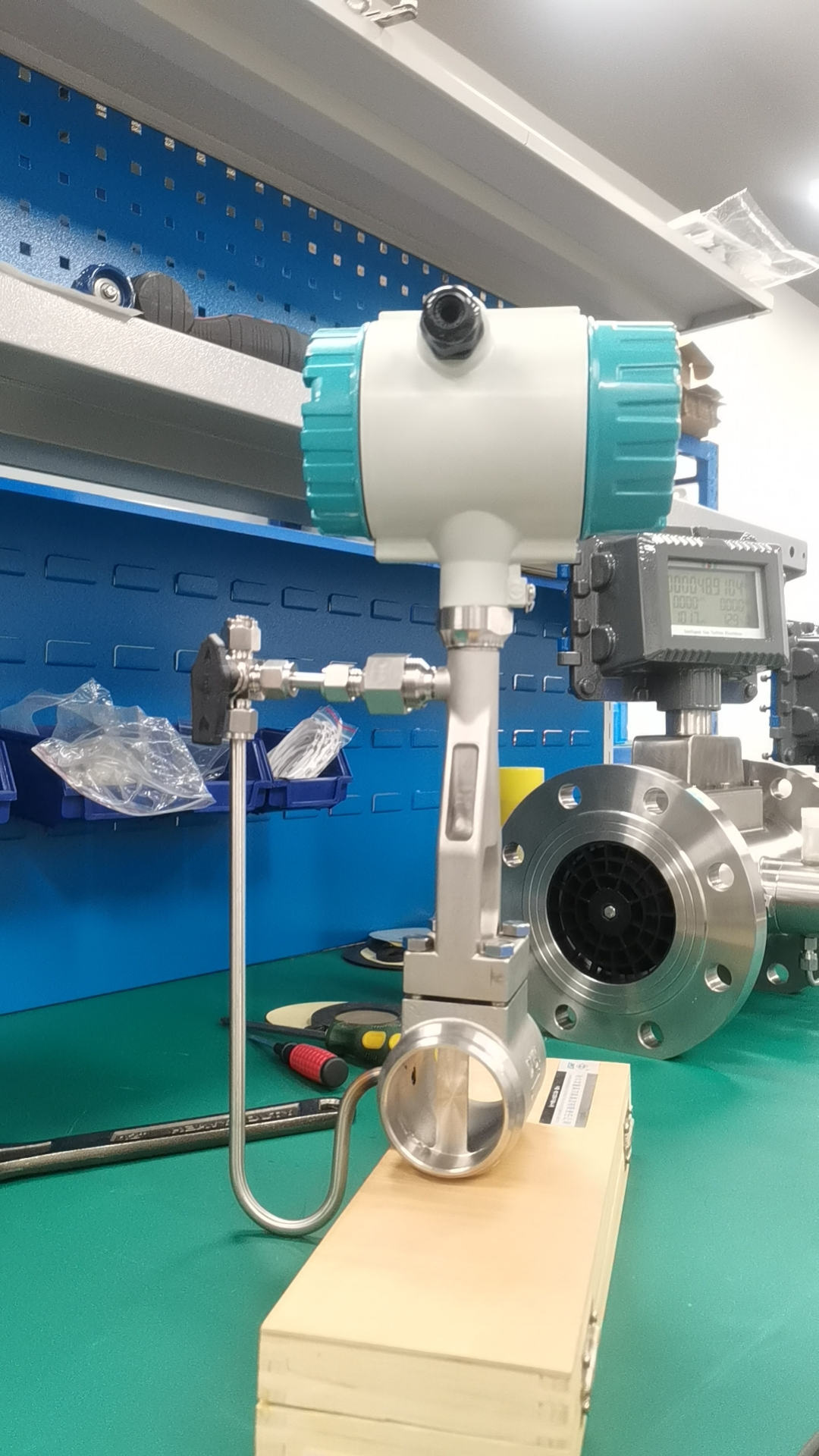

2. Different uses require different surface layers to be selected. The surface of the primary steam-producing equipment and the primary steam-consuming units should be equipped with flow meters with active density compensation. Especially for the flow meters used in trade settlement, they should be as accurate as possible and calibrated regularly. For secondary energy-consuming units such as workshops and canteens in internal accounting, flow meters with fixed value compensation can be used to reduce costs. It can also meet the requirements of dynamic statistical balance.

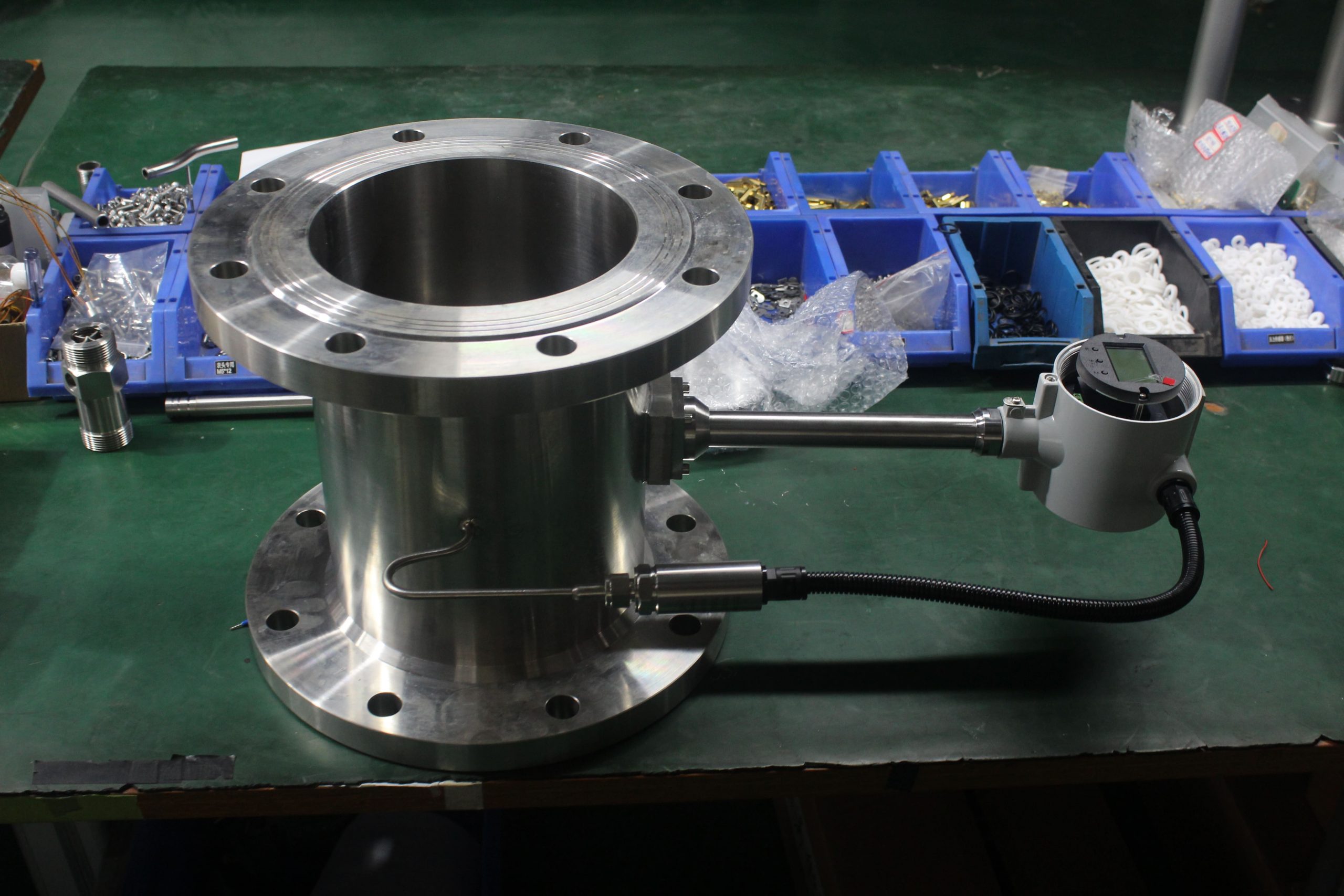

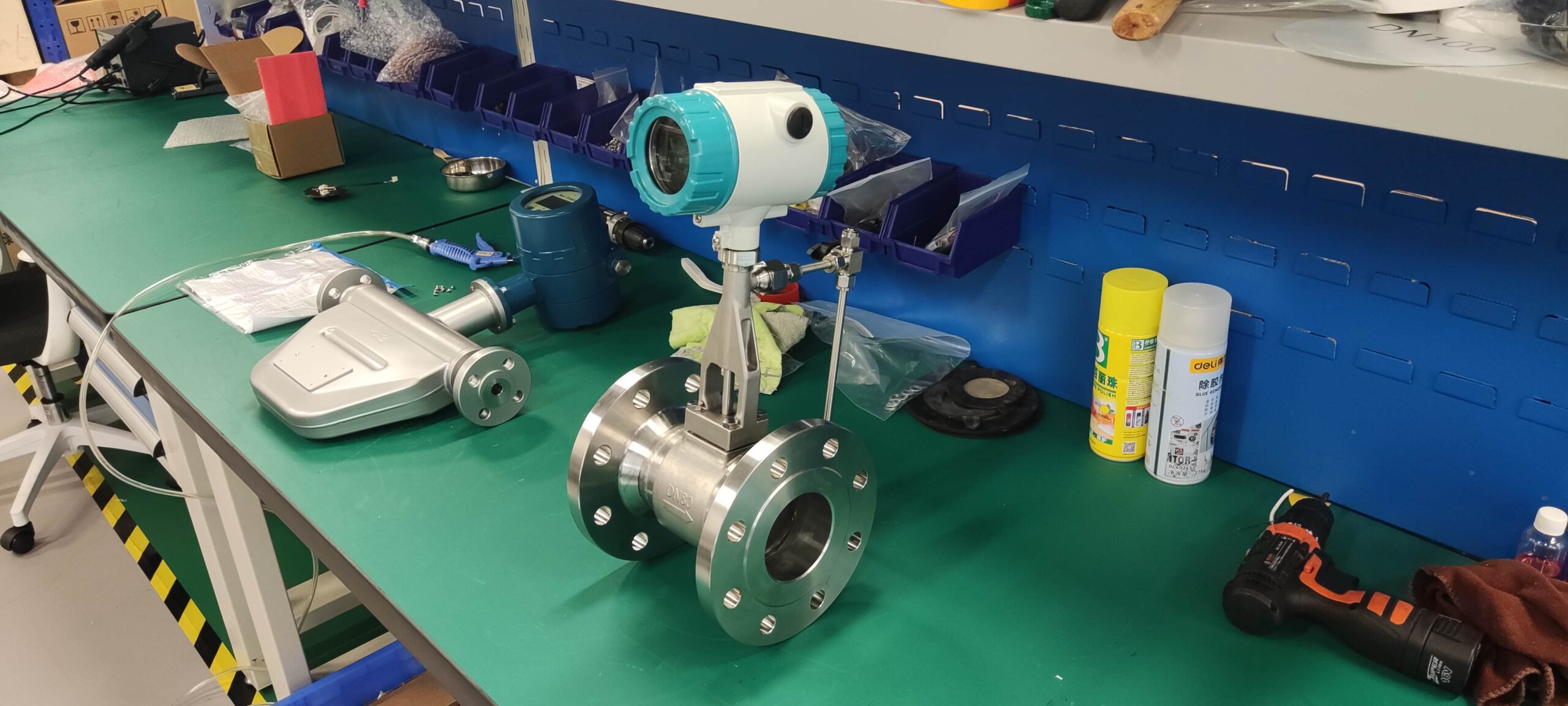

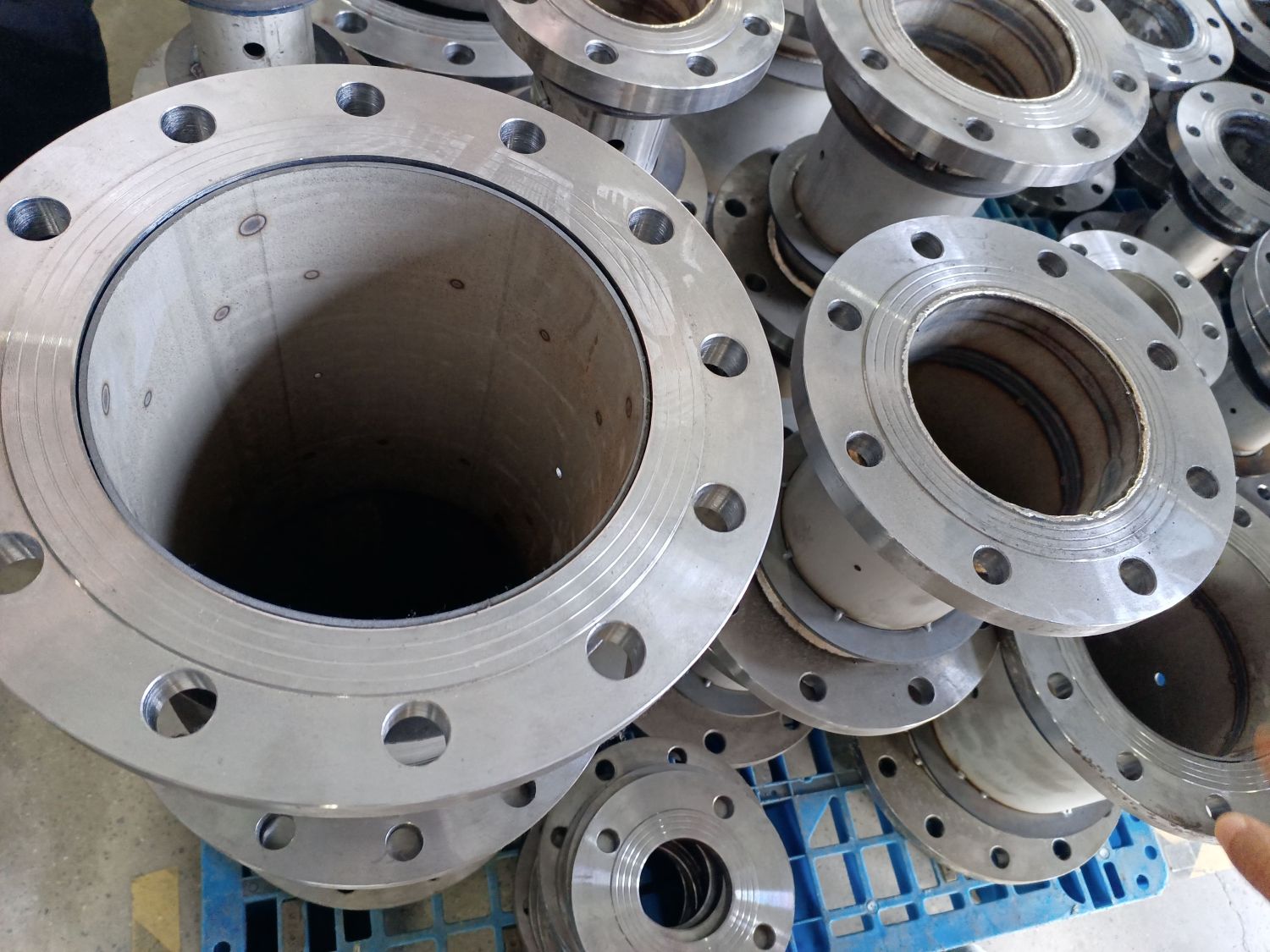

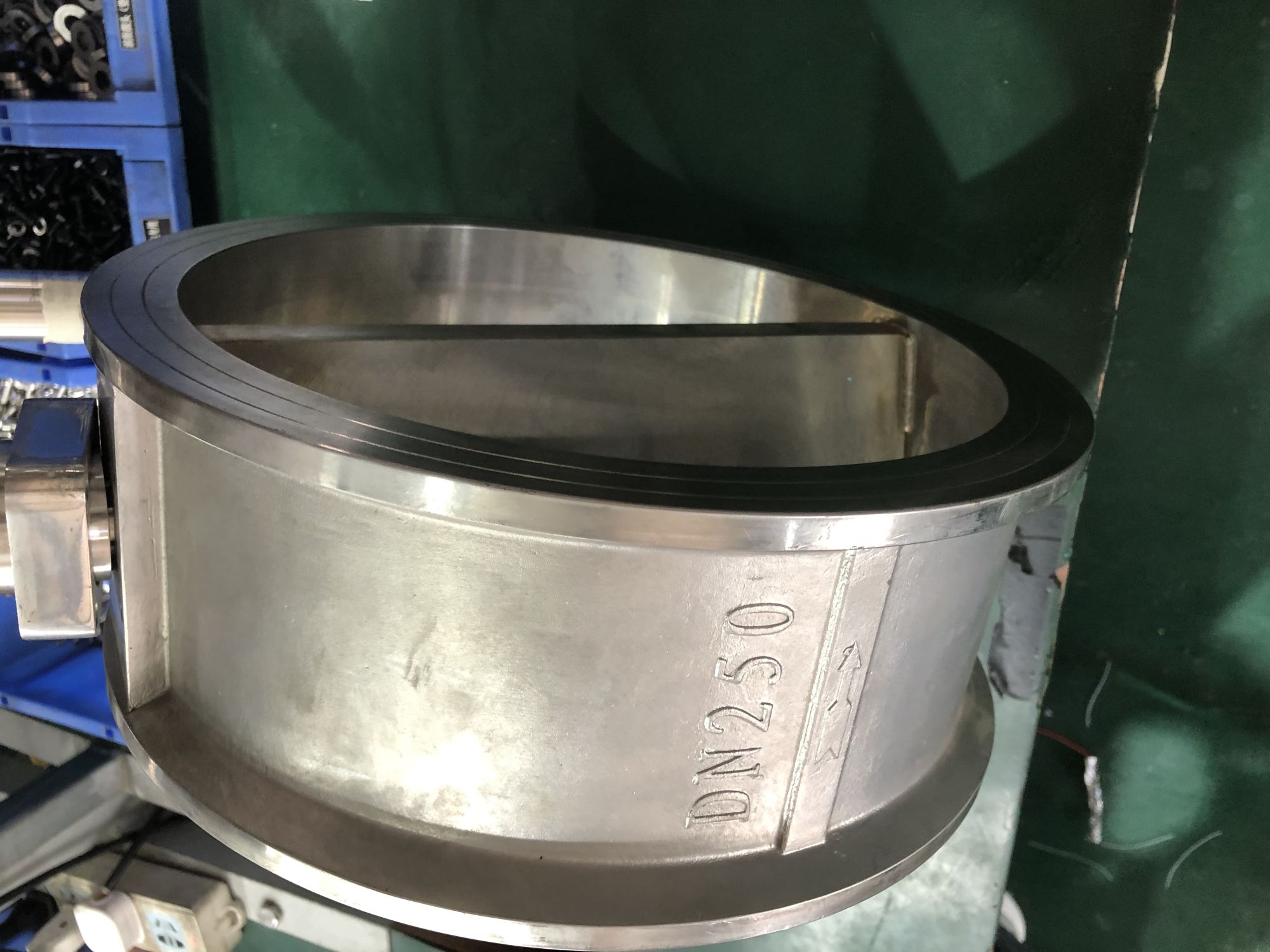

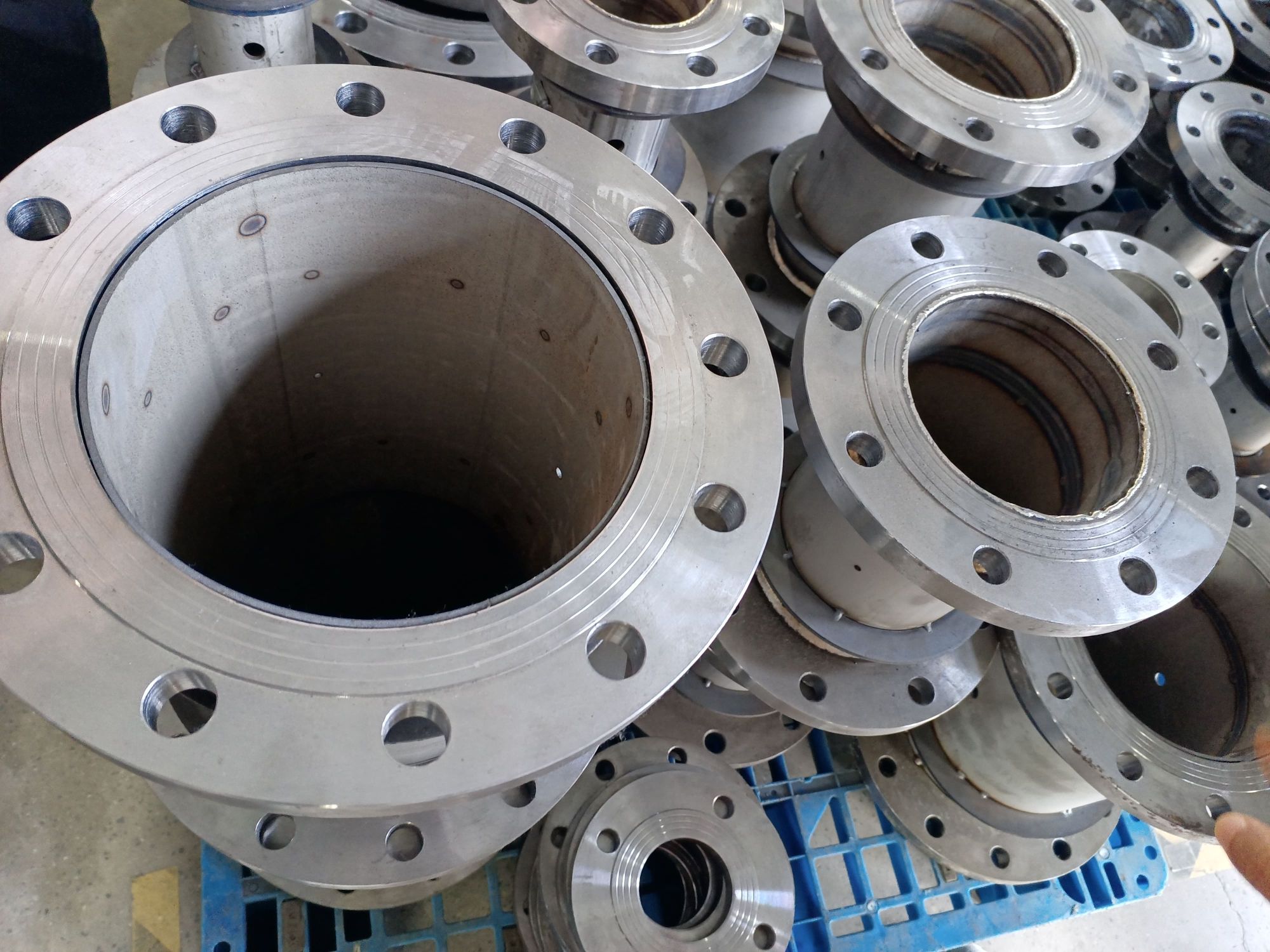

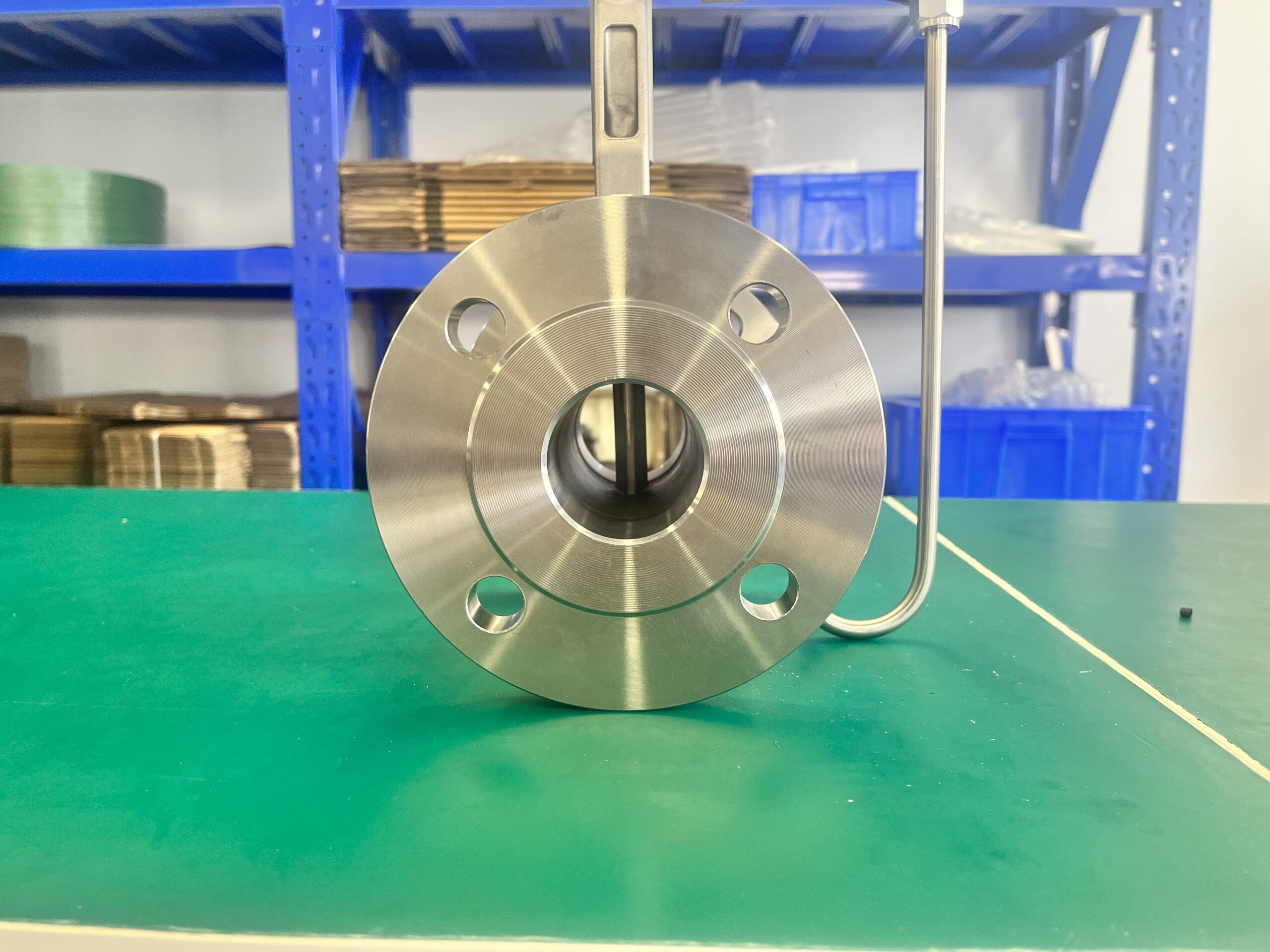

3. Install flowmeters with a diameter of DN200mm or less. When the steam temperature is below 300℃, vortex flowmeters should be installed. Steam flowmeters with a diameter of DN200mm or more and a temperature above 300℃ should be equipped with differential pressure flowmeters.

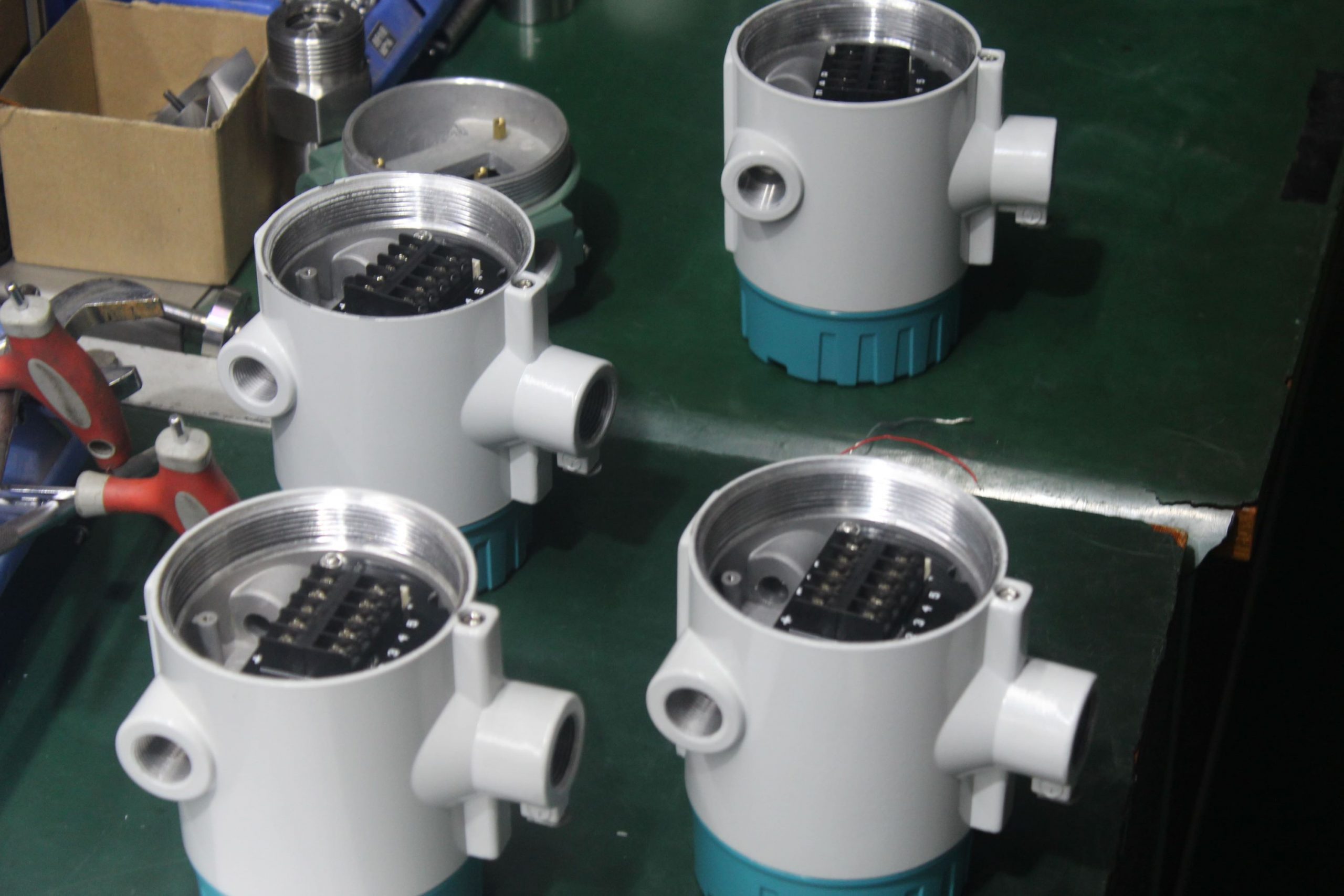

4. When choosing a surface supplier, it is necessary to check whether they have a verification device. Factories without verification equipment cannot ensure the accuracy and reliability of the surface.

5. It is necessary to clarify the nature of the steam, whether it is saturated steam or superheated steam. Under unstable conditions of pressure and temperature, to ensure the accuracy of measurement, temperature and pressure gauges should be added to the surface equipment for active density compensation.

6. A differential pressure flowmeter should be installed for the total steam production of the power generation boilers in the power plant.

7. The size of the outer diameter should be selected based on the flow rate, not the pipe diameter. Since steam pipes are generally selected with larger diameters to minimize pipe resistance as much as possible. To prevent forgetting at low flow rates, it is advisable to choose a suitable surface diameter as much as possible. The principle is to choose the smaller rather than the larger.

In conclusion, when purchasing a steam flowmeter, do not only consider the quotation. Instead, based on the actual situation of your own unit, choose the best one. The principle of proximity and location should be adhered to. As steam flow measurement is a dynamic measurement, some doubts and malfunctions are inevitable. To ensure the normal operation of the measurement and eliminate malfunctions in a timely manner, purchasing a steam flowmeter nearby can prevent many troubles from occurring.