Ultrasonic flowmeter can not be ignored maintenance points

Ultrasonic flowmeter installation, use and maintenance is simple and fast, but there are still some points can not be ignored, today the flowmeter manufacturer Aister meter for the maintenance of ultrasonic flowmeter points to make the following explanation.

1, ultrasonic flow meter zero flow check

When the pipeline liquid is stationary, and there is no strong magnetic field interference around, no strong vibration, the meter head is displayed as zero, at this time, the zero point is automatically set to eliminate the zero drift, and small signal cutting must be done during operation, usually, the flow is less than 5% of the full flow, automatic cutting. The zero point can also be adjusted through the menu.

2, ultrasonic flow meter panel keyboard operation

Before moving the instrument, it is necessary to set the parameters effectively, for example, using the unit system, installation mode, pipe diameter, pipe wall thickness, pipe material, pipe roughness, fluid type, two probe spacing, flow rate unit, smaller speed, larger speed, etc. Only when all parameters are entered correctly can the meter correctly display the actual flow value.

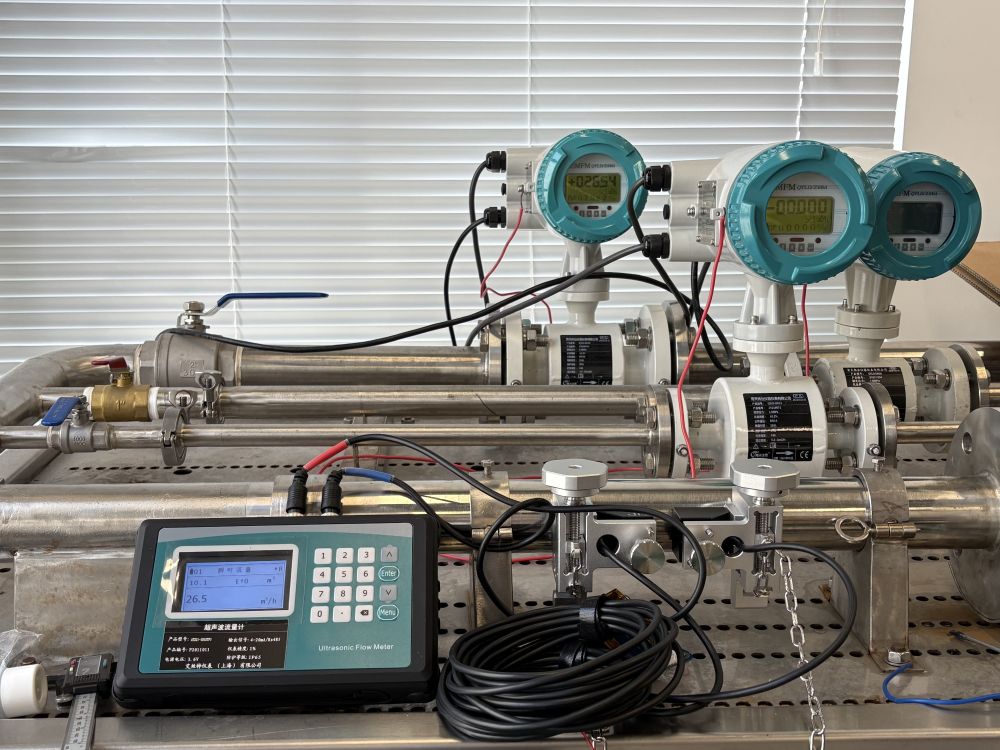

3. Regular calibration of ultrasonic flowmeter

In order to ensure the accuracy of the flowmeter, it is necessary to carry out regular calibration, usually using a portable flowmeter with higher precision for direct comparison, using the measured data to calculate: error = (measured value – standard value)/standard value, using the calculated relative error, correction factor, so that the measurement error meets the error of ±2%, you can meet the measurement requirements.

4, ultrasonic flow meter regular maintenance

For the external transducer ultrasonic flowmeter, there is no water pressure loss after installation, no potential water leakage, just check regularly whether the transducer is loose and whether the adhesive between the pipeline is good; The plug-in ultrasonic flowmeter should regularly clean the impurities, scale and other water leakage deposited on the probe; If it is an integrated ultrasonic flowmeter, it is necessary to check whether the flange connection between the flowmeter and the pipe is good, and consider the impact of field temperature and humidity on other electronic components. Regular maintenance can ensure the long-term stable operation of the ultrasonic flowmeter.