Key points of ultrasonic flowmeter selection for different installation methods

In the face of many types of ultrasonic flowmeters, users should choose a reasonable selection according to the actual situation and measurement needs. Today, the flowmeter manufacturer Aister meter gives you a detailed introduction to the selection of ultrasonic flowmeters with different installation methods.

1, Doppler ultrasonic flowmeter

It can only be used to measure fluids containing an appropriate amount of particles or bubbles that can reflect ultrasonic signals, such as factory discharge fluids, untreated sewage, and factory process fluids with stable impurity content. It is more demanding on the measured medium, neither clean water, impurity content should be relatively stable, only in this way can be measured normally, and the performance of the instrument produced by different manufacturers and the requirements of the tested manufacturers are not the same. The selection of this kind of ultrasonic flowmeter must not only know the medium to be measured, but also have an in-depth understanding of the performance, accuracy and requirements of the selected ultrasonic flowmeter.

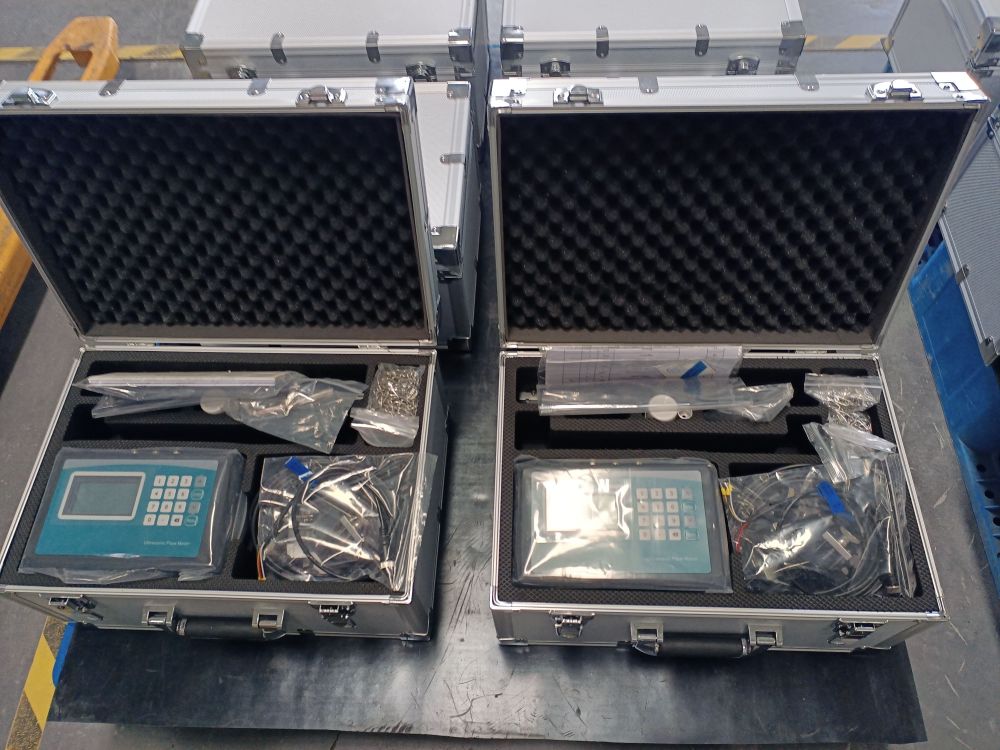

2, portable ultrasonic flowmeter

It is suitable for temporary measurement, mainly used to check the operation status of other flow meters installed on the pipeline, carry out fluid balance test in an area, check the flow situation of the pipeline at that time, etc. If not fixed installation, the choice of portable ultrasonic flowmeter is convenient and economical.

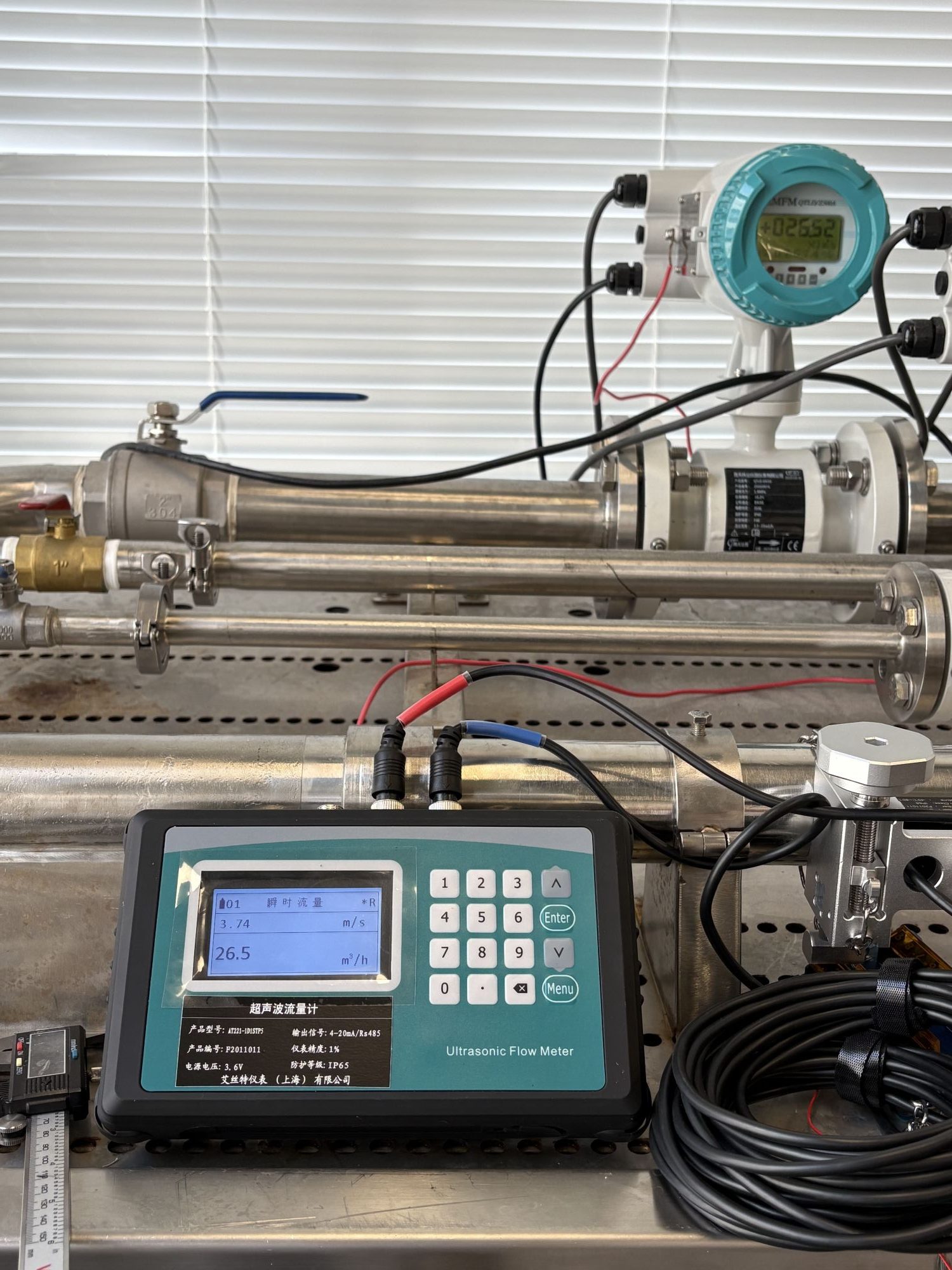

3, time difference ultrasonic flowmeter

At present, the most widely produced and applied ultrasonic flowmeter is the time difference type. It is mainly used to measure clean fluid flow, and is widely used in the field of water supply companies and industrial water. In addition, it can also measure homogeneous fluids with low impurity content (impurity content less than 10g/L, particle size less than 1mm). Such as sewage and other media flow, accuracy up to ±1.5%. The practical application shows that the use of time difference ultrasonic flowmeter can achieve satisfactory results in the measurement of the corresponding fluid.

4, pipe segment ultrasonic flowmeter

The highest accuracy, up to ±0.5%, and is not limited by pipe material, lining, suitable for flow measurement accuracy requirements of high occasions. However, with the increase of pipe diameter, the cost will also increase, usually, the selection of small and medium-sized diameter pipe segment ultrasonic flowmeter is more economical.

5, fixed ultrasonic flowmeter

If there is enough installation space, the plug-in transducer is used instead of the external transducer, and the fixed ultrasonic flowmeter can completely eliminate the influence of pipe lining, scaling and pipe wall on the attenuation of ultrasonic signal, and the measurement stability is higher, and the maintenance workload is greatly reduced. Moreover, because plug-in transducers can be installed without interruption, their applications are becoming more and more widespread.