Flowmeter manufacturers teach you how to quickly select ultrasonic flowmeter installation position

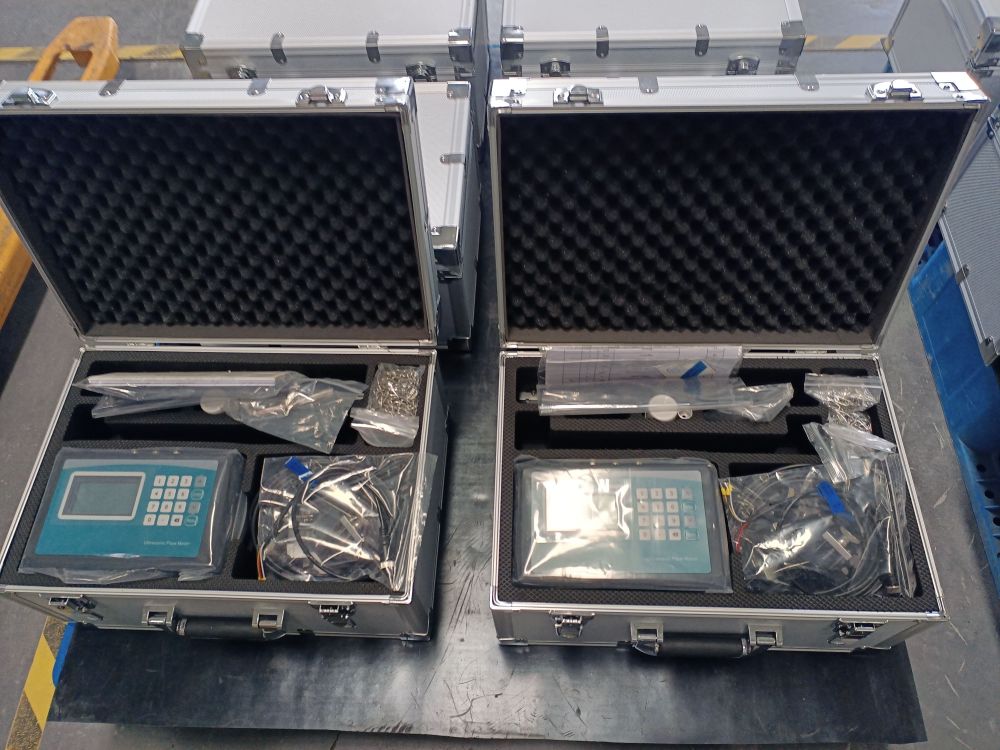

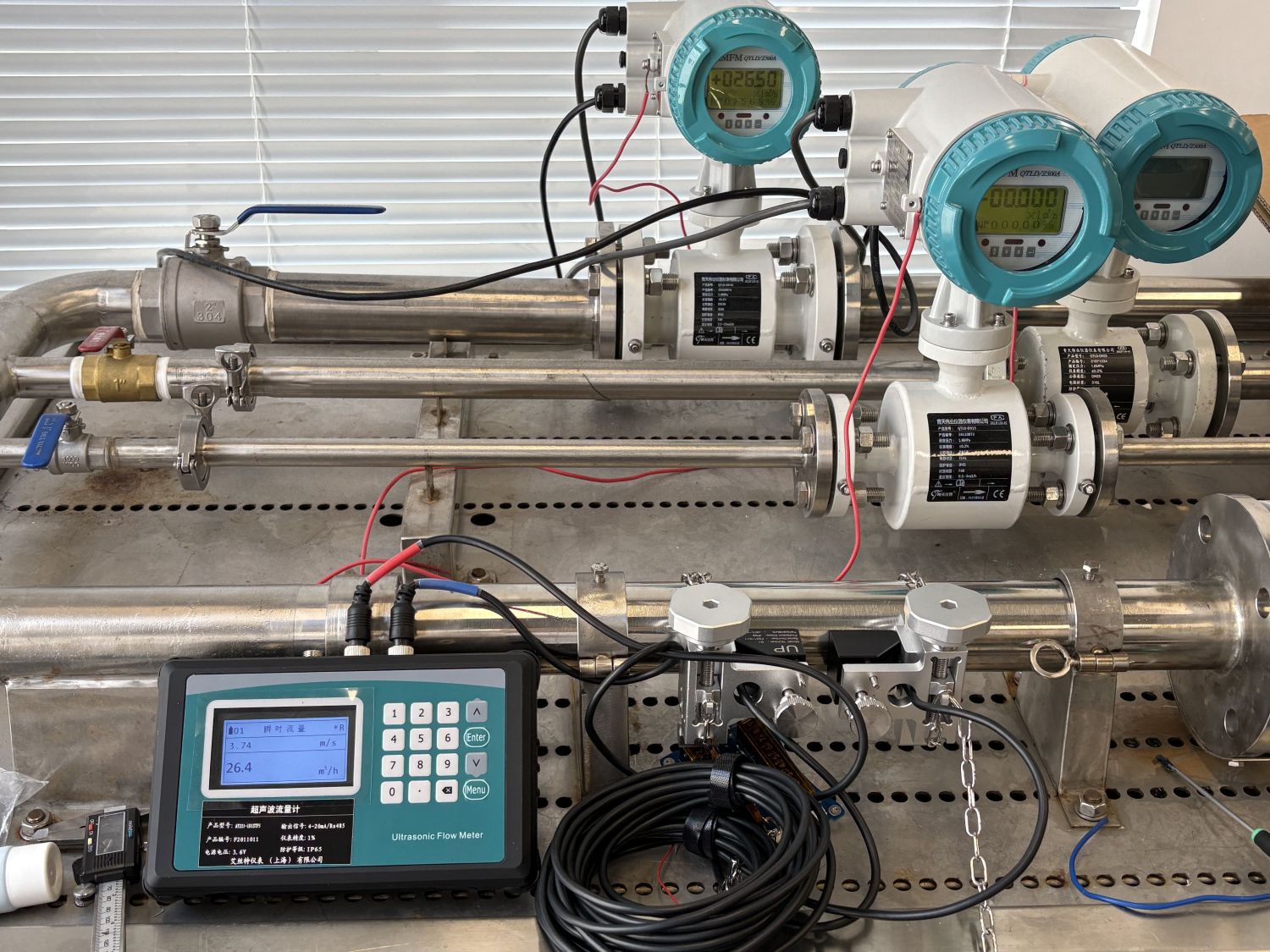

The installation of the ultrasonic flowmeter is simple and convenient in the installation of all flowmeters, as long as you choose a suitable measuring point, input the pipe parameters at the measuring point into the flowmeter, and then fix the probe on the pipe. Today, flowmeter manufacturer Aister instrument makes the following analysis for you on this topic.

In order to ensure the measurement accuracy, the selection of measuring points requires the selection of uniform parts of the fluid flow field, generally should follow the following principles:

1, choose a pipe segment full of fluid with uniform material and dense quality and easy ultrasonic transmission, such as a vertical pipe segment (fluid flow upward) or a horizontal pipe segment.

2, the installation distance should be selected upstream greater than 10 times the straight pipe diameter, downstream greater than 5 times the straight pipe diameter without any valve, elbow, diameter reduction and other uniform straight pipe section, the installation point should be fully away from the valve, pump, high voltage and frequency converter interference sources.

3, avoid installation at the high point of the pipeline system or vertical pipe with free outlet (fluid flow down)

4, for open or half-full pipes, the flow meter should be installed in the U-shaped pipe section

5, fully consider the scale of the inner wall of the pipe, as far as possible to choose a non-scale pipe section for measurement. If it cannot be satisfied, it is necessary to consider the scaling as the lining for better measurement accuracy.

6, to ensure that the temperature and pressure at the measurement point can be within the working range of the sensor.

7. The two sensors are installed in the horizontal direction of the axial surface of the pipeline, and are installed within the range of ±45o at the horizontal position of the axis to prevent the phenomena such as unsatisfactory pipes, bubbles or precipitation at the bottom from affecting the normal measurement of the sensor. If it is not possible to install horizontally and symmetrically due to the space limitation of the installation site, the sensor can be installed vertically or at an Angle under the condition that the upper part of the tube is free of bubbles.

8. Select a pipe segment with uniform and dense pipes and easy ultrasonic transmission.